Thermal circulation type elevated heatable brick bed

An overhead kang, thermal cycle technology, applied in the heating mode, furnace combustion air/flue gas circulation, household heating and other directions, can solve problems such as poor convection heat transfer, improve thermal efficiency, save energy, simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

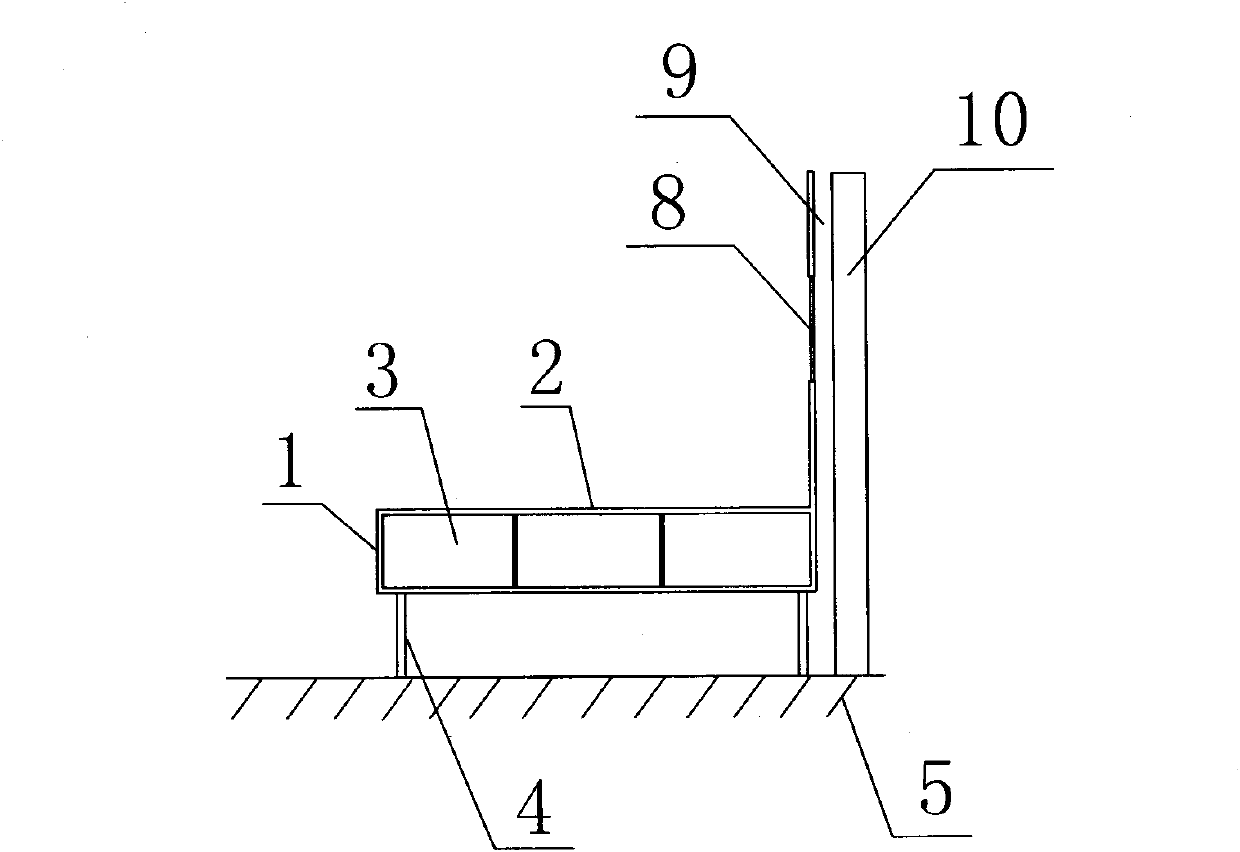

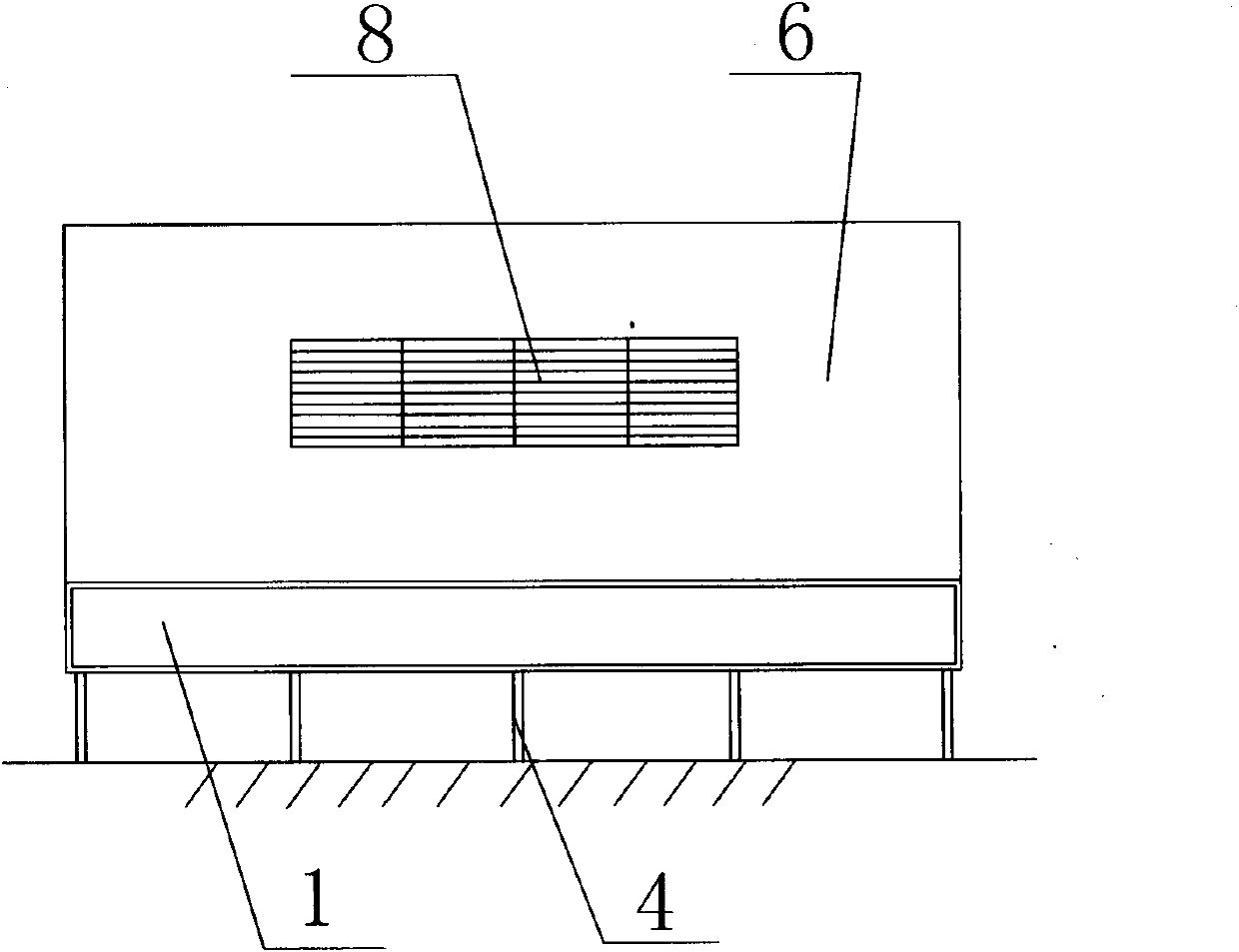

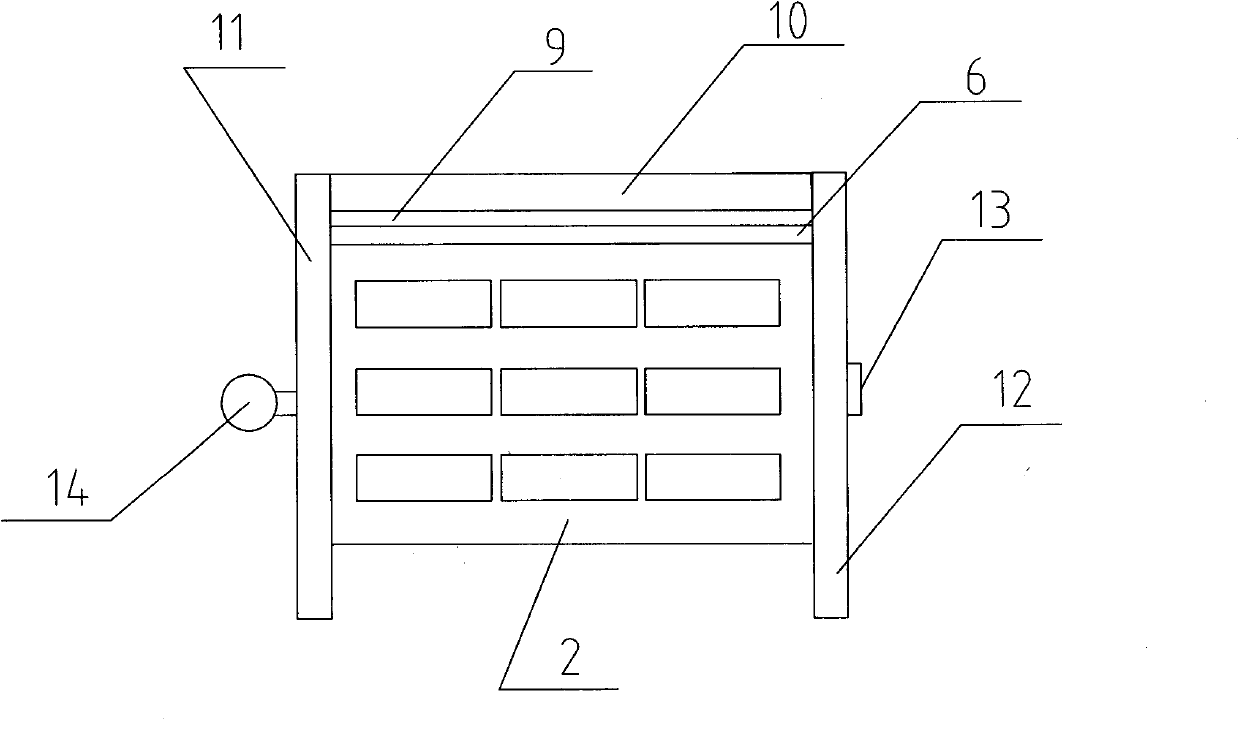

[0018] to combine figure 1 , figure 2 , image 3 As shown, there is a flue 3 in the body 1 of the thermal cycle overhead kang, and the body 1 contacts the ground 5 through the support column 4, and the support column 4 supports the body 1 away from the ground 5, so that the bottom surface of the body 1 An air channel is formed between the ground 5, the left and right sides of the kang body 1 are respectively built with the left side wall 11 and the right side wall 12, and the back of the kang body 1 is a heat dissipation wall 6, and the heat dissipation wall 6 stands on the kang surface 2, Behind the cooling wall 6 is the back wall 10 of the room, the cooling wall 6 is separated from the back wall 10, the space between the two is the air flow channel 9, the top of the air flow channel 9 is the outlet of the circulation port, the air channel and the The air flow passage 9 is connected, and the two form a right-angle passage. The heat dissipation wall 6 is made of heat dissi...

Embodiment 2

[0020] Figure 4 It is a side sectional view of Embodiment 2 of the present invention. As shown in the figure, the difference between this heat-circulating overhead kang and the thermal-circulation overhead kang in Embodiment 1 is that there is a row of support columns 4 on the front of the kang body 1, and the kang body There is also a row of supporting columns 4 behind the 1, wherein the supporting columns 4 at the back directly lean against the back wall 10 of the room, and the kang body 1 is seated on the supporting columns 4, and the upper end surface of the supporting columns 4 is partially exposed outside the kang body 1. This way is more stable because the support column 4 leans against the back wall 10 , and the part of the support column 4 exposed outside the kang body 1 is formed as the air flow channel 9 between the heat dissipation wall 6 and the back wall 10 .

[0021] The present invention designs the structure of heated kang according to the principle of chimne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com