Panel display and protecting structure for same

A flat-panel display, protective structure technology, applied in instruments, identification devices, etc., can solve problems such as the defective rate of optical films

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The invention provides a protective structure, which can slow down the pressure on the backlight module caused by the withstand voltage test and reduce the defective rate of product functions.

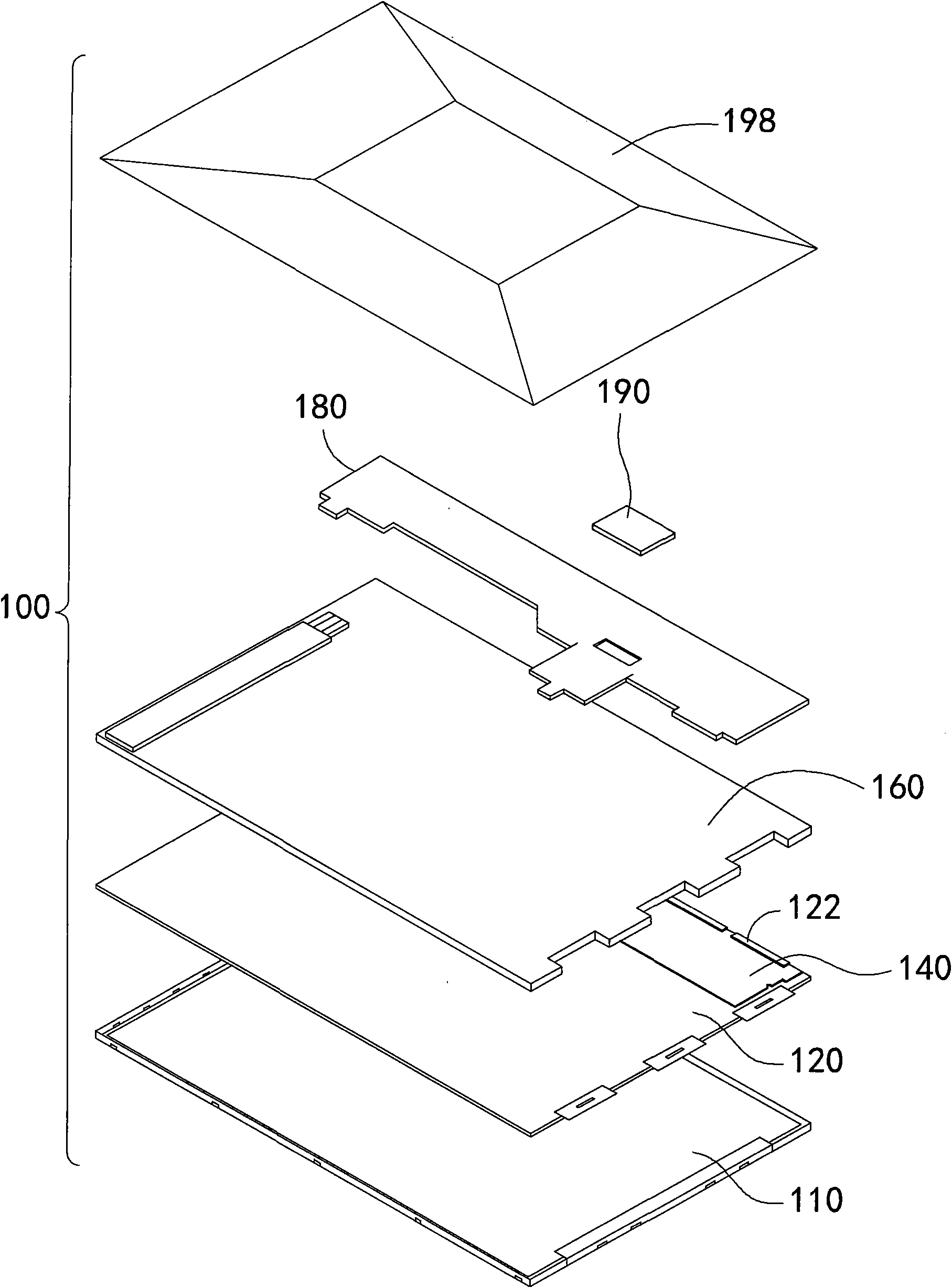

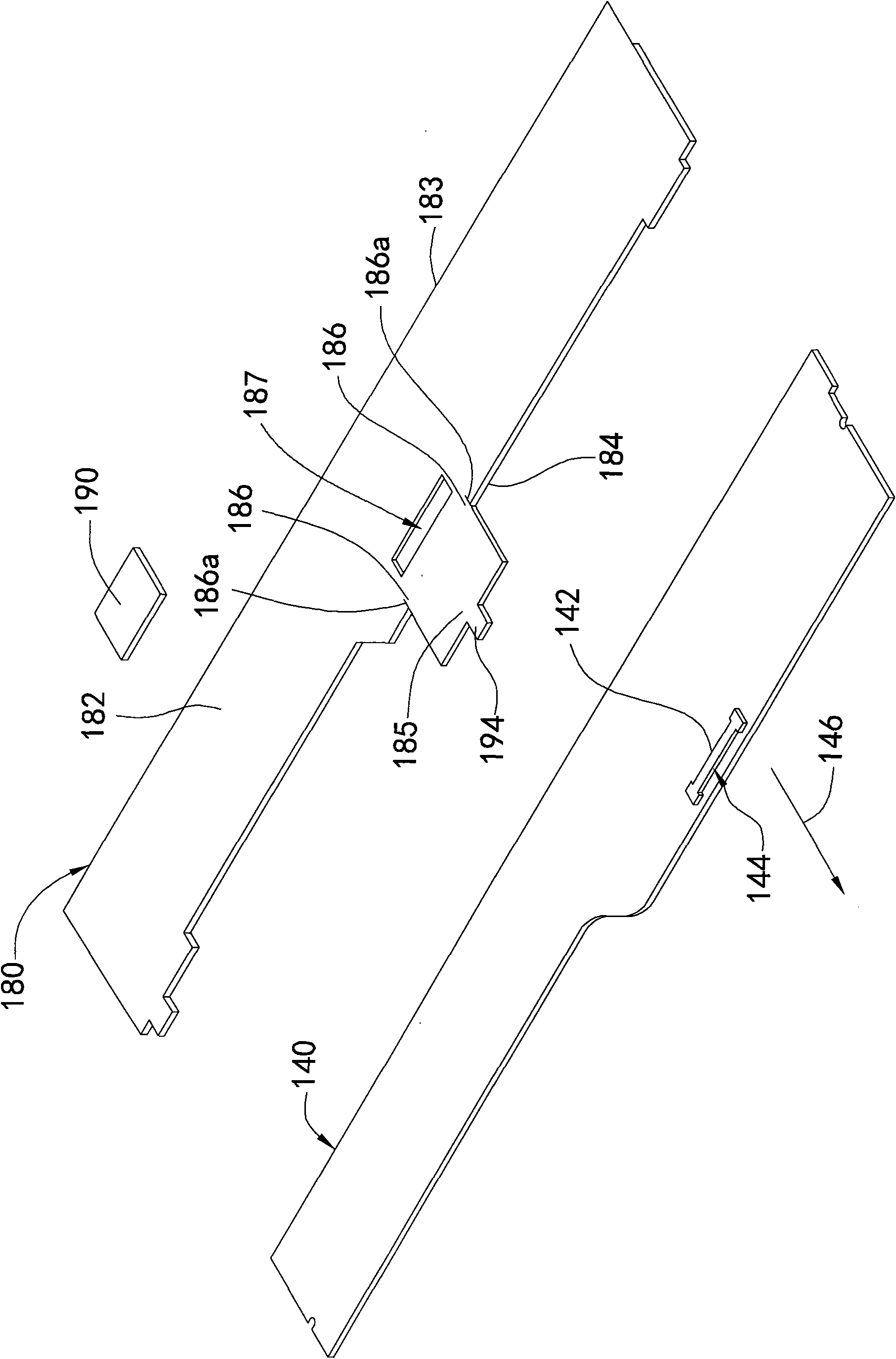

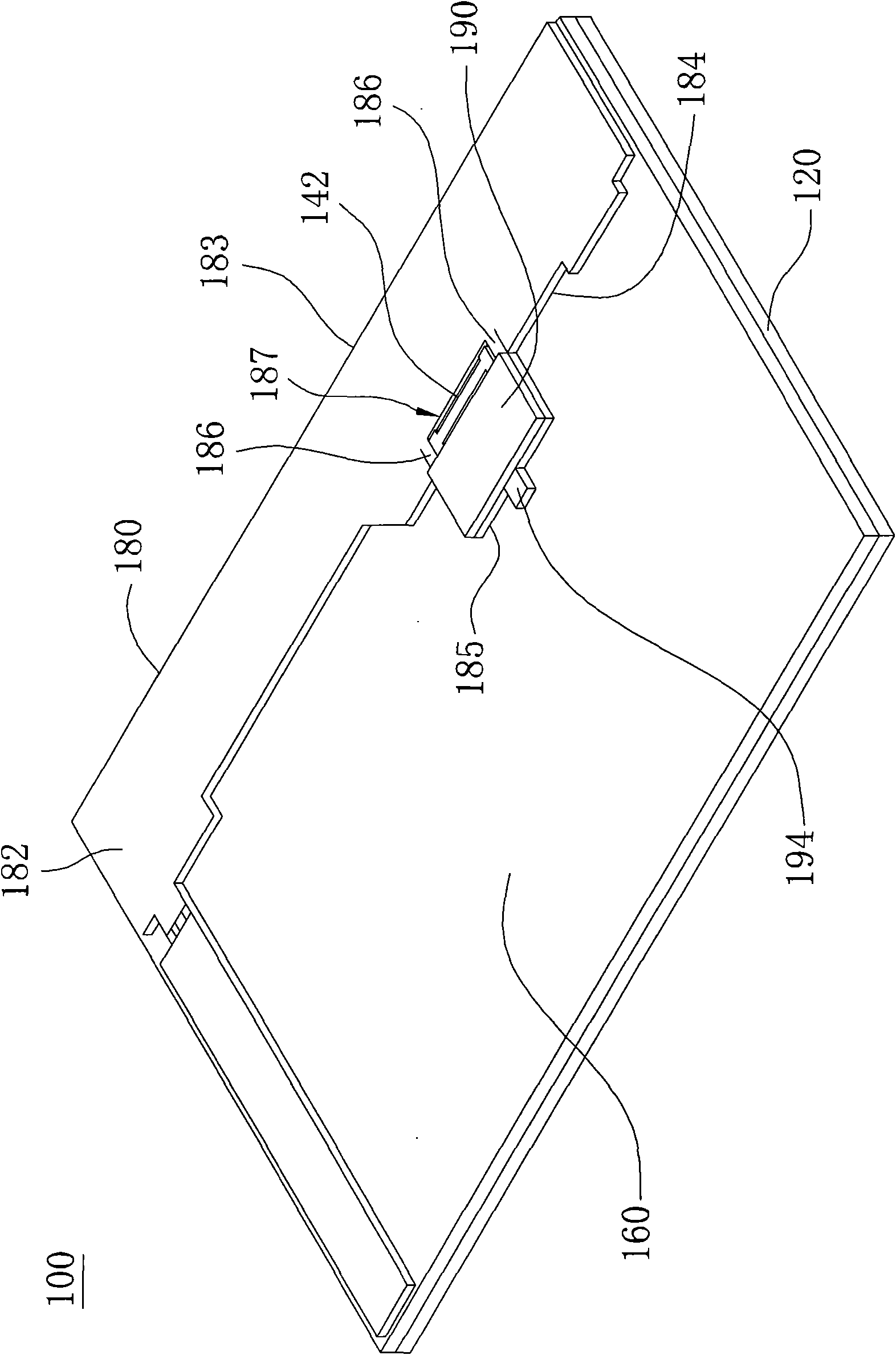

[0052] figure 1 An exploded view of a flat panel display according to a preferred embodiment of the present invention is shown. exist figure 1 Among them, the flat panel display 100 includes a front iron frame 110 , a display panel 120 , a circuit board 140 , a backlight module 160 , a protective structure 180 and a back shell 198 . In this embodiment, the front iron frame 110 is located on the display side of the display panel 120 . The circuit board 140 is connected to the display panel 120 through a chip on film (COF) 122 . When the backlight module 160 is assembled between the display panel 120 and the back case 198 , the circuit board 140 needs to be turned up and placed between the backlight module 160 and the back case 198 . The protective structure 180 is covered on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com