High lighting effect pattern substrate and manufacturing method thereof

A graphics substrate, high light efficiency technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of low luminous efficiency of LED light sources, achieve the effects of enhancing reflection efficiency, reducing defect density, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

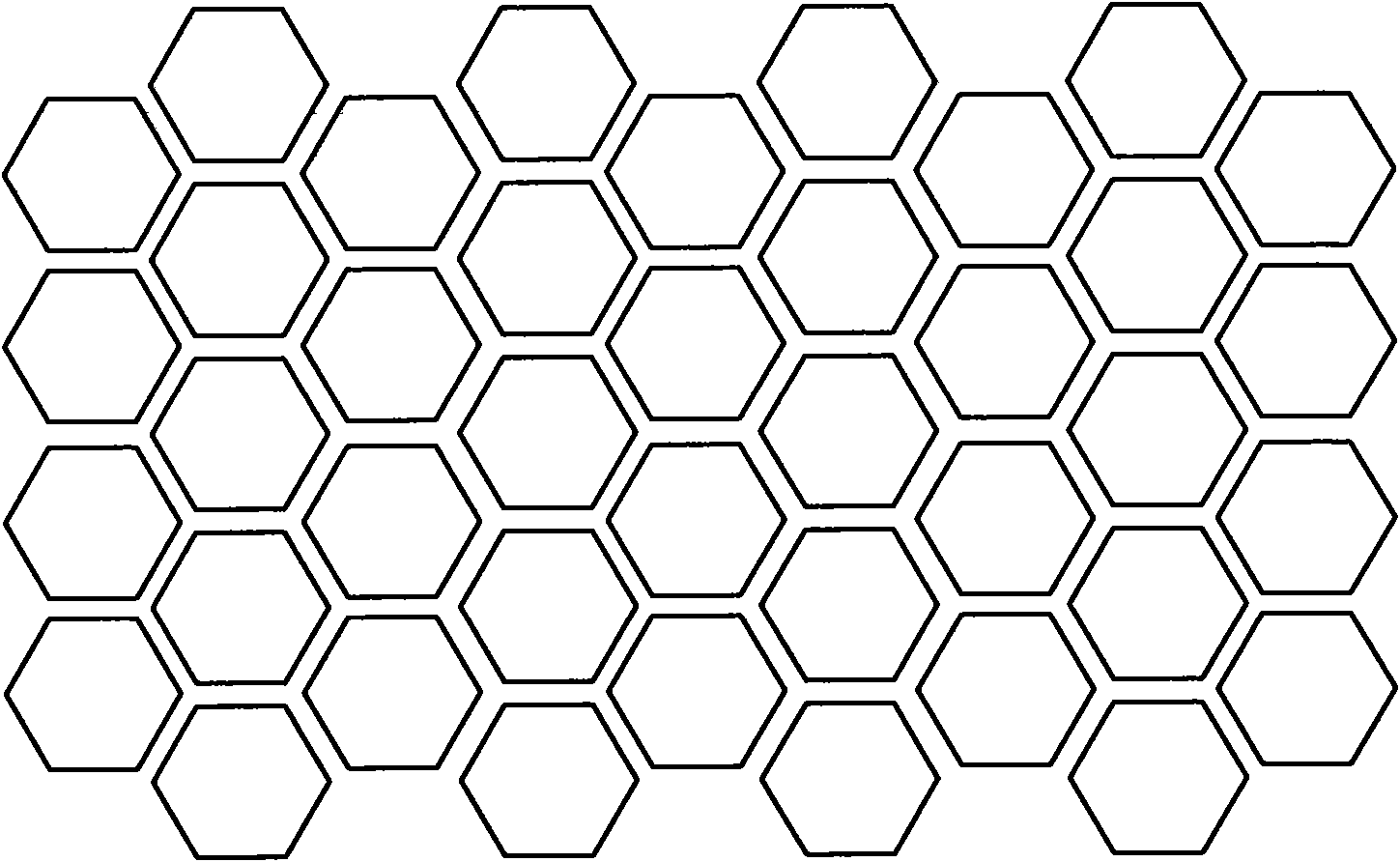

[0033] Such as figure 1 As shown, the arrangement of the centrally symmetric figures as regular hexagons is as follows: another regular hexagon equal to the side lengths of the above regular hexagons is respectively arranged at an equal vertical distance from the outside of the six sides of each regular hexagon. The adjacent side lengths of the adjacent regular hexagons are parallel to each other, and extend around the substrate based on the above-mentioned centrosymmetric figure, so that the vertical distance between the side lengths of two adjacent regular hexagons is the same, which is 0.2-2um , the side length of the regular hexagon is 0.2-2.5um.

no. 2 example

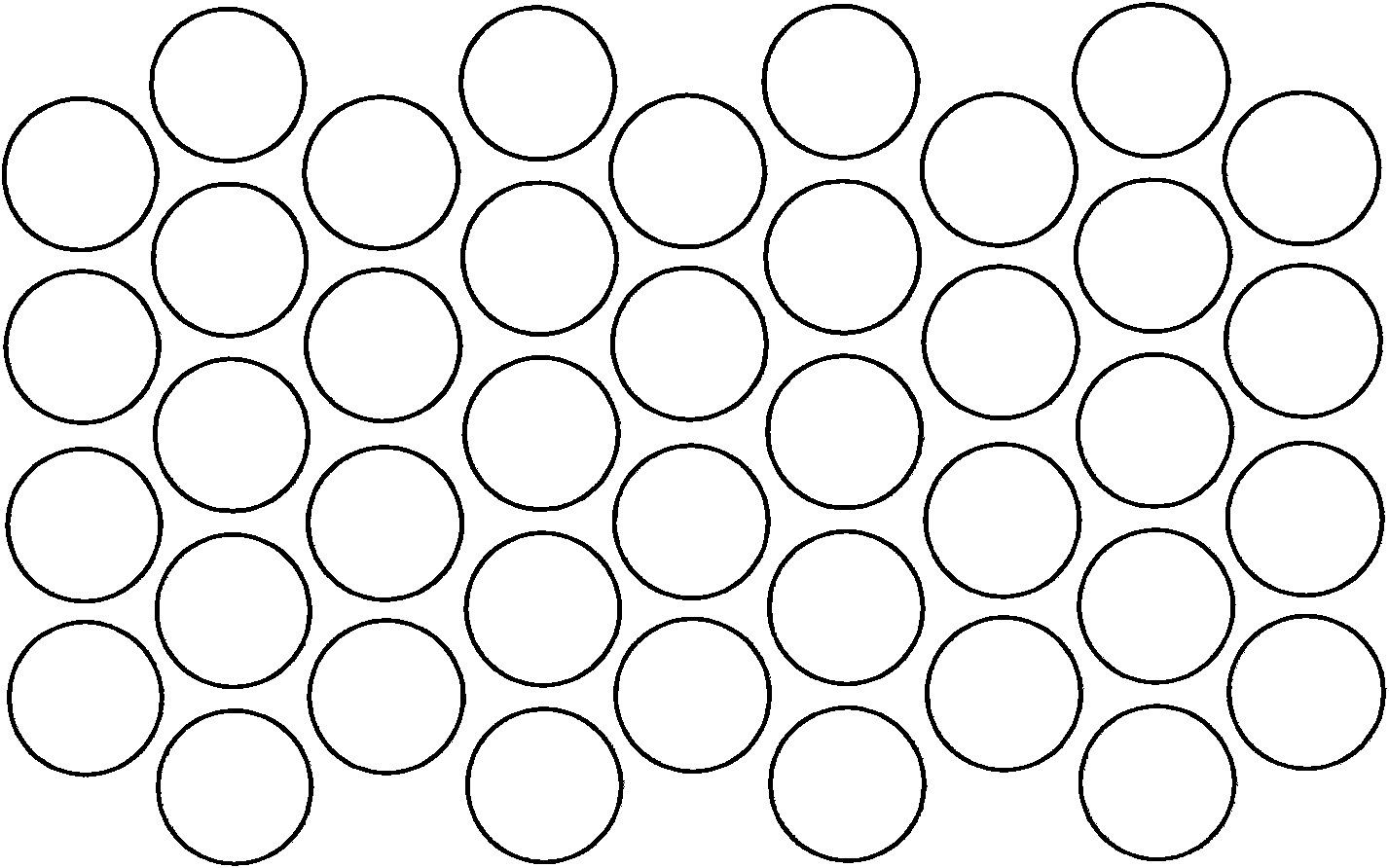

[0035] Such as figure 2 As shown, the arrangement of the centrally symmetrical figure as a circle is as follows: the radius of two adjacent circles is the same and the distance between the centers of the two circles is equal, and the above-mentioned centrally symmetrical figure is used as the reference unit to extend around the substrate. The lengths of adjacent circles are parallel to each other, and extend around the substrate with the above-mentioned centrosymmetric figure as a reference unit, so that the shortest distance between the circumferences of two adjacent circles is the same, which is 0.2-1.5um. The radius of its circle is 0.2-4um.

no. 3 example

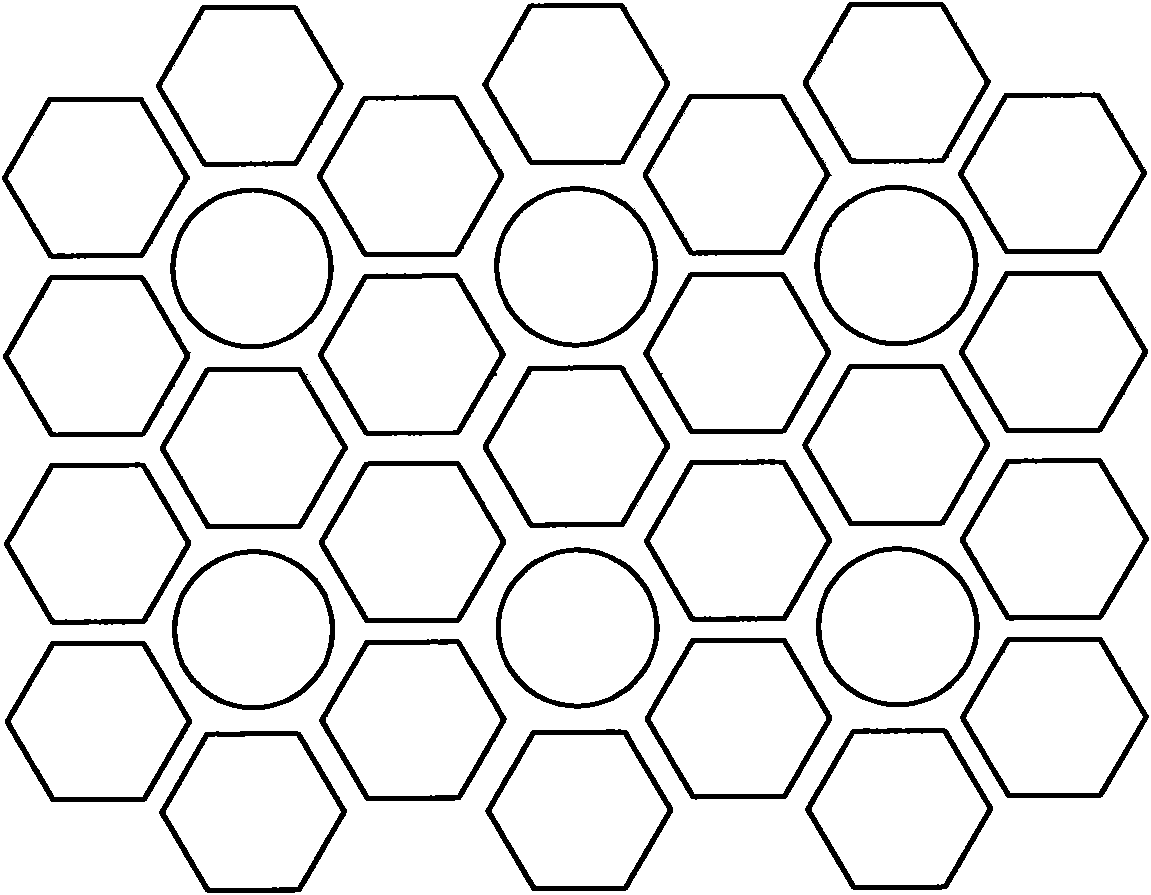

[0037] Such as image 3 As shown, the centrosymmetric figure is a regular hexagon composed of a circle in the center and six symmetrically distributed identical regular hexagons separated from the circle. Another regular hexagon that is equal to the side length of the regular hexagon circumscribed by the above-mentioned circle, the adjacent side lengths of adjacent regular hexagons are parallel to each other, and the radius of the circle is 1 / 2 of the side length of the regular hexagon Times, using the above-mentioned centrosymmetric figure as the reference unit to extend around the substrate, so that the vertical distance between the side lengths of two adjacent regular hexagons and the shortest distance between the circle and the adjacent regular hexagons are the same, both It is 0.2-2um, and the side length of its regular hexagon is 0.2-2.5um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com