Packaging method of soft-package lithium ion battery

A lithium-ion battery and packaging method technology, applied in the direction of non-aqueous electrolyte storage battery, electrolyte storage battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of polluted batteries, electrolyte extraction volume deviation, electrolyte retention volume deviation, etc., to achieve Effects of reducing contamination and corrosion, reducing extraction volume, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

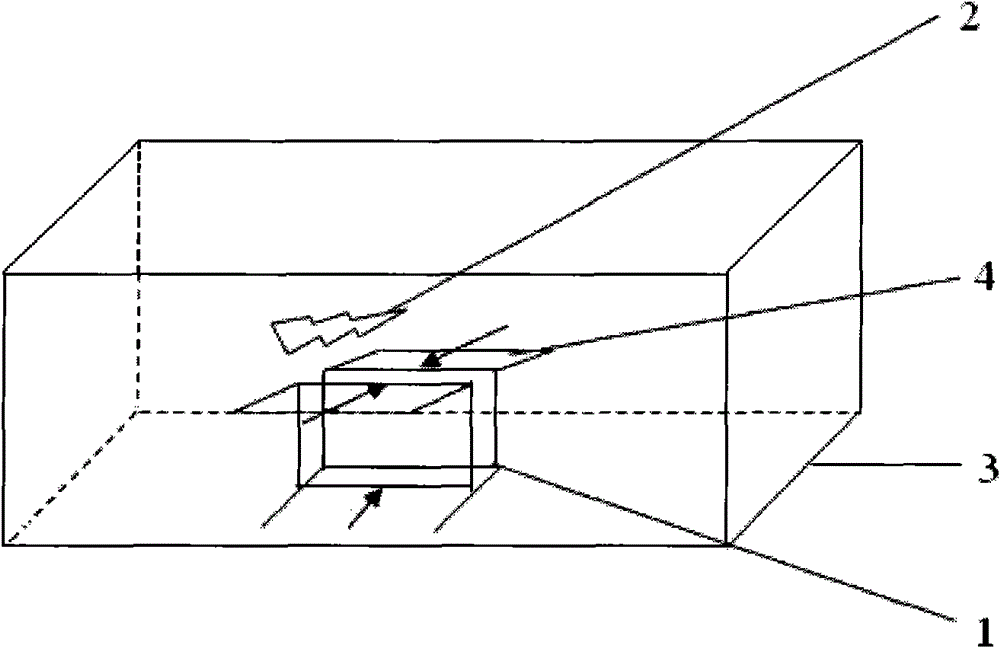

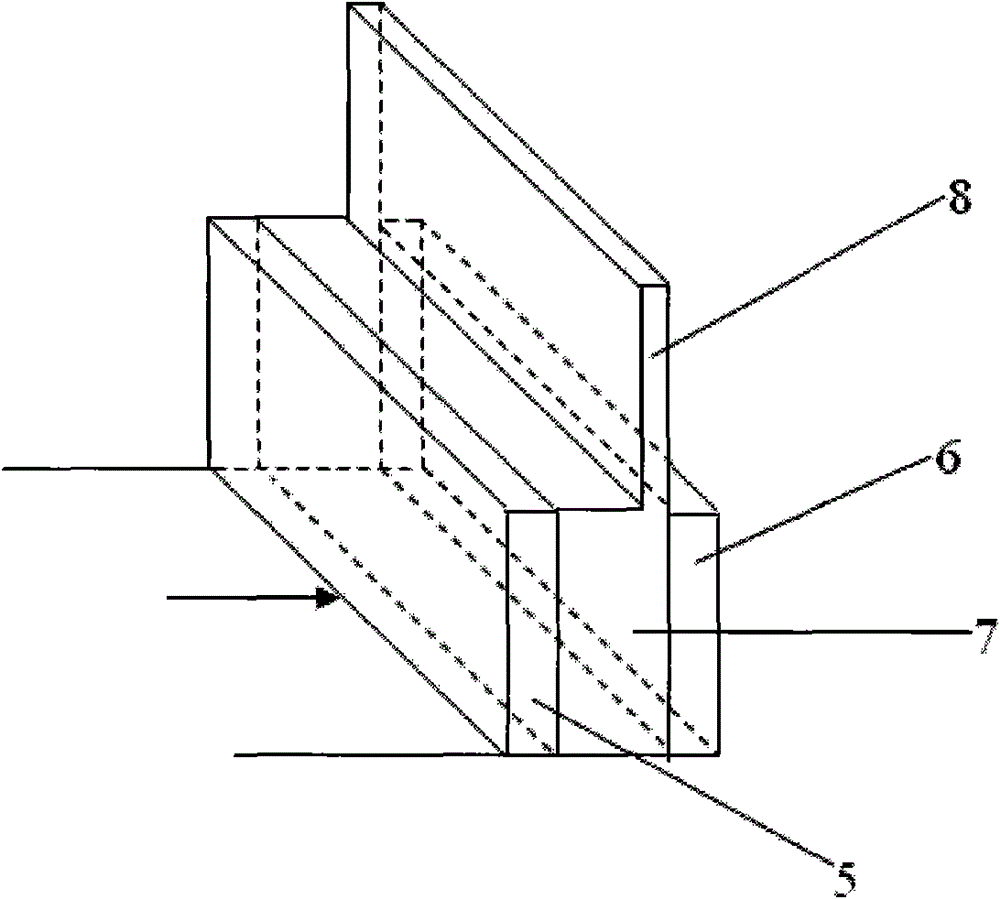

[0024] First, place the battery to be packaged between the front clamp 5 and the rear clamp 6 of the battery fixing fixture 1 with the air bag 8 facing upwards. The angle between the battery body 7 and the horizontal plane is 90 degrees, and the air bag 8 and the battery body 7 The connection part of the battery is always higher than the battery body 7; then, the battery fixing fixture 1 and the battery to be packaged are sent into the vacuum chamber 3 together, the air bag 8 is pierced with the bayonet 2, and the vacuum chamber 3 is evacuated in a vacuum pumping manner , to reach a vacuum degree of -90KPa; finally, the battery is thermally sealed with the heat sealing jig 4, thereby completing the exhaust packaging process of the battery to be packaged.

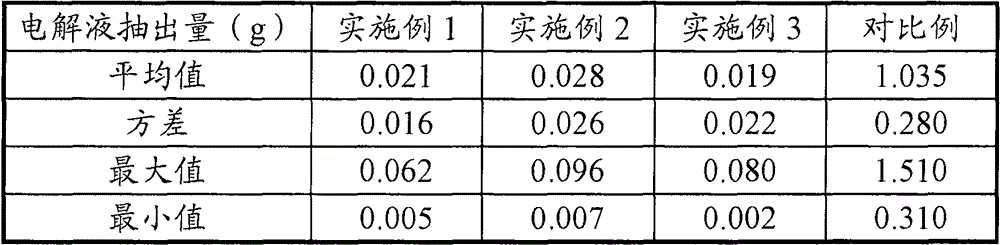

[0025] By weighing the weight of the battery before and after venting packaging, the electrolyte extraction amount can be calculated, that is, the electrolyte extraction amount = the weight of the battery before venting packa...

Embodiment 2

[0028] The steps of exhausting the battery to be packaged in this embodiment are basically the same as those in Example 1, the only difference being that when the battery to be packaged is fixed between the front clamp 5 and the rear clamp 6, the angle between the battery body 7 and the horizontal plane is 45 degrees, The air bag 8 is at the higher end of the battery body 7 . Moreover, the vacuuming of the vacuum chamber 3 is carried out in three incremental steps, and the vacuum degrees achieved three times are respectively -10Kpa to -40Kpa, -40Kpa to -70Kpa and -70Kpa to -101.325Kpa.

[0029] According to the method of this embodiment, the packaging of 30 batteries to be packaged is completed, and the data of the amount of electrolyte extracted is calculated and recorded.

Embodiment 3

[0031] The steps of degassing and packaging the battery to be packaged in this embodiment are basically the same as those in Embodiment 1, the only difference being that the vacuuming of the vacuum chamber 3 is carried out in three incremental steps, and the degree of vacuum achieved three times is from -30Kpa to - 40Kpa, -60Kpa to -70Kpa and -80Kpa to -90Kpa.

[0032] According to the method of this embodiment, the packaging of 30 batteries to be packaged is completed, and the data of the amount of electrolyte extracted is calculated and recorded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com