Method for cutting off brittle material substrate

A brittle material substrate, substrate technology, applied in the direction of stone processing equipment, glass cutting equipment, stone processing tools, etc., to achieve the effect of inhibiting the generation of micro-cracks or glass shavings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation methods, methods, steps, Features and their functions are described in detail below.

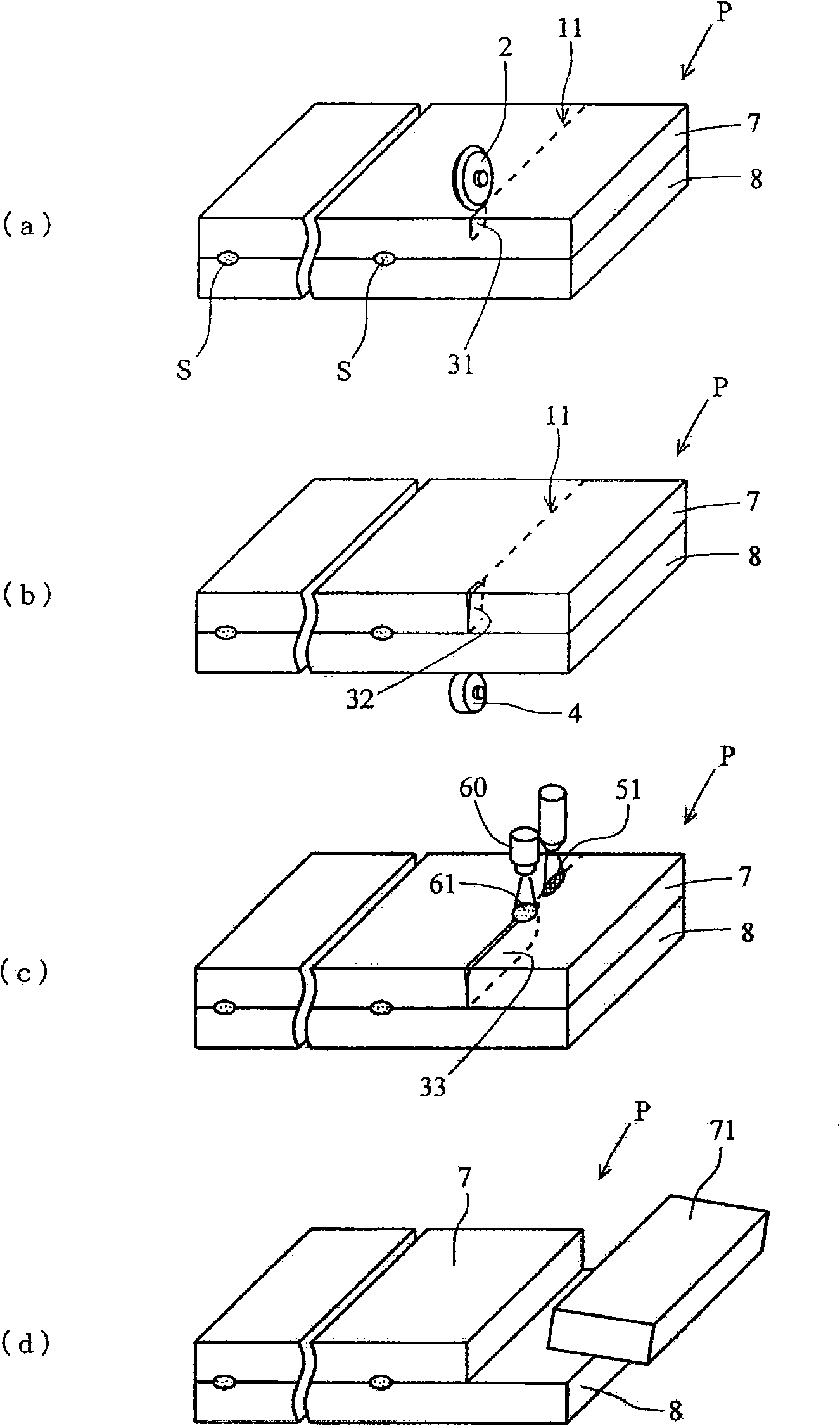

[0037] figure 1 (a) to figure 1 (c) is a process diagram showing an embodiment of the cutting method of the brittle material substrate of the present invention. figure 1 It is a process diagram in the case of cutting the glass substrate 1 which is a brittle material substrate with the line 11 to cut. as figure 1 As shown in (a), an initial crack 31 is first formed at the cutting start end As of the surface 10a of the glass substrate 1 by the cutter wheel 2 . The length and depth of the initial cracks 31 are not particularly limited, but usually the length of the initial cracks 31 is preferably in the range of 1 to 30 mm, more preferably in the range of several mm. In addition, the depth of the initial crack 31 is prefer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com