Filter device of sand blaster

A filter device and sandblasting machine technology, which is applied in the direction of used abrasive processing devices, gravity filters, abrasives, etc., can solve problems such as increased probability of defective products, unreasonable filter devices, and scratches on the appearance of products. Achieve the effect of saving labor costs and production costs, high production efficiency, and maintaining normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

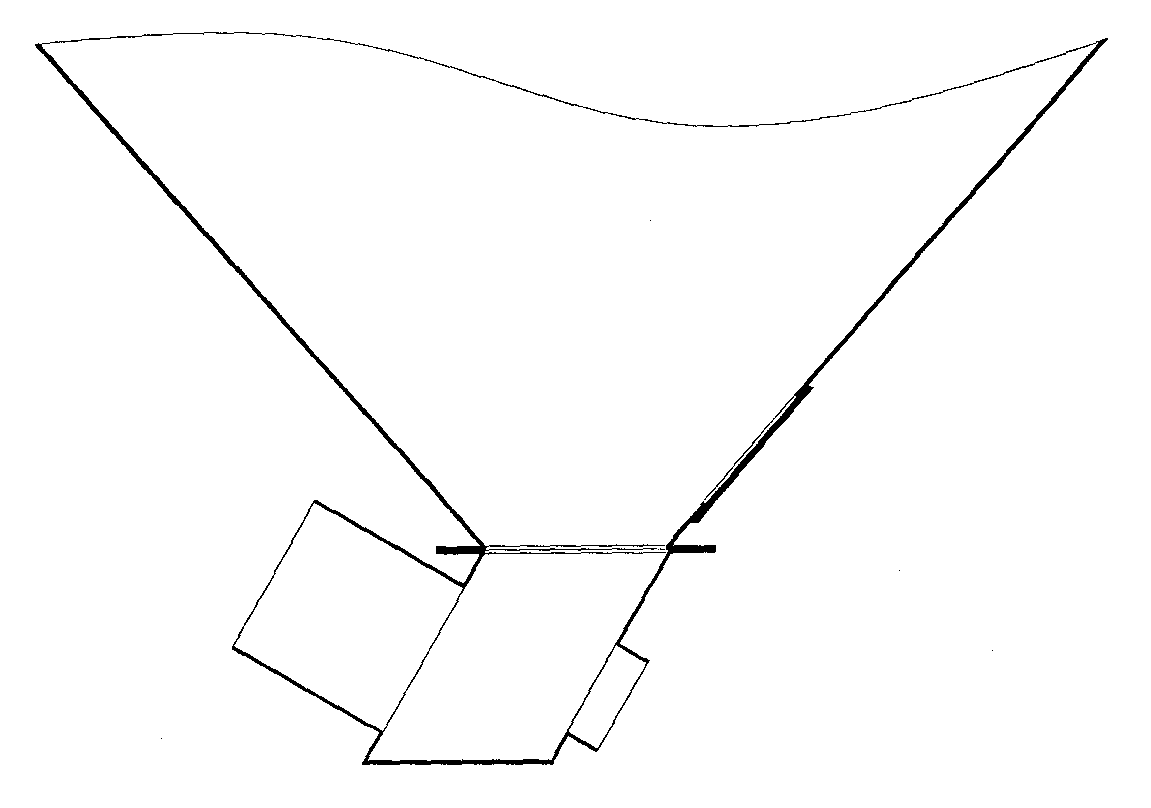

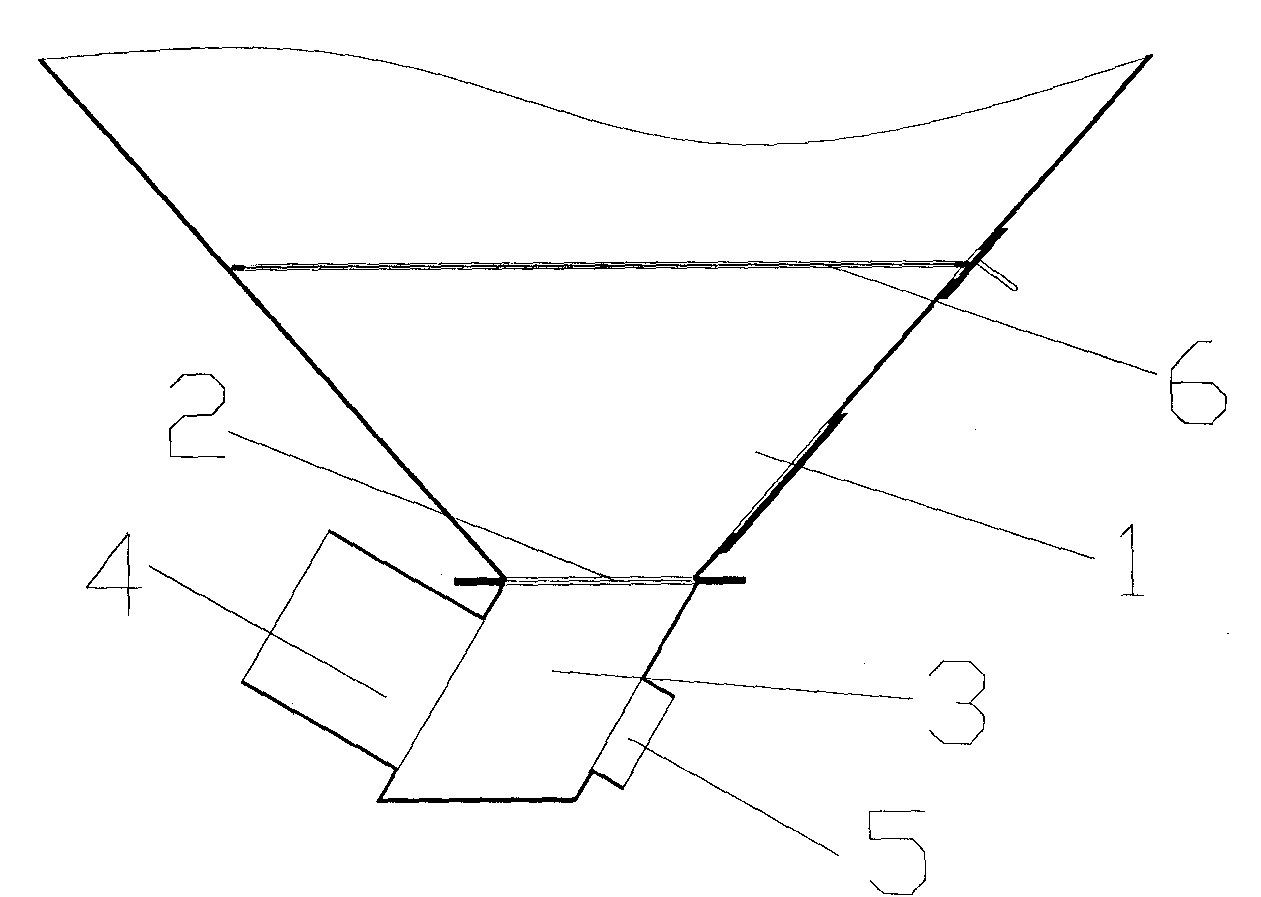

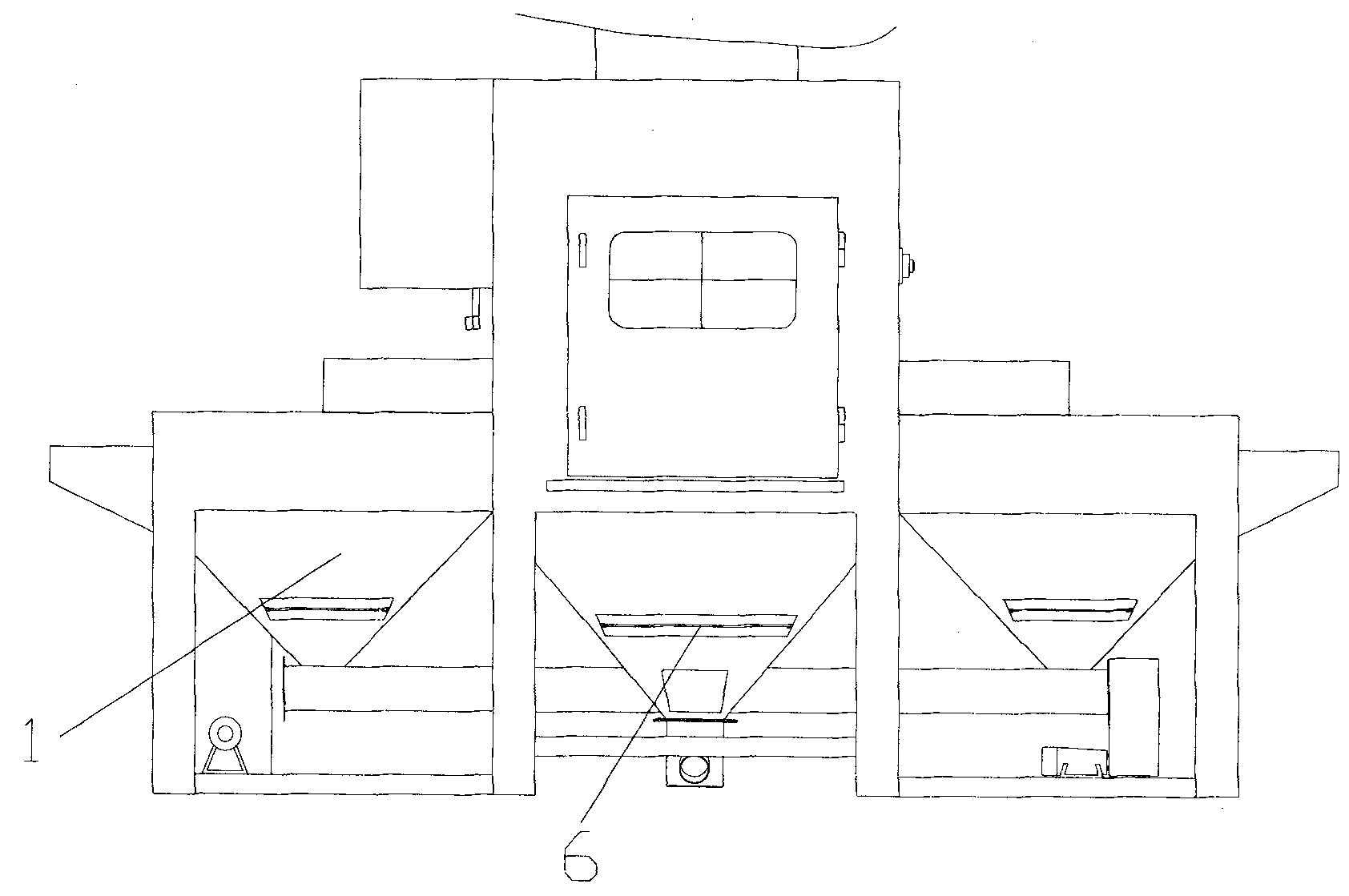

[0011] Such as figure 2 and 3 As shown, a filter device for a sandblasting machine includes a sand collecting bucket 1, a layer of filter screen 2 is arranged at the bottom of the sand collecting bucket 1, a channel 3 is provided below the filter screen 2, and a suction filter is provided on one side of the channel 3 upwards. Abrasive holes 4, dredging holes 5 are arranged downwards on the other side of the channel 3, and a pull-out filter 6 is arranged above the filter 2 in the middle of the sand collection bucket 1. The abrasive material passed through the filter screen 2 is sucked into the spray head through the abrasive material suction hole 4 for spraying.

[0012] The basic principles and main features of the invention and the advantages of the invention are shown and described. Those skilled in the industry should understand that the present invention is not...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap