Rotating cathode roll roller for electrolysis

A technology of rotating cathodes and rollers, which is applied in the direction of electrodes, electrolysis, electroforming, etc., can solve the problems of not being able to ensure sufficient and effective filling, not being able to achieve normal and uniform conduction, and not being able to effectively suppress hot spots, so as to suppress the generation of hot spots, The effect of avoiding unstable contact and stabilizing the contact state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

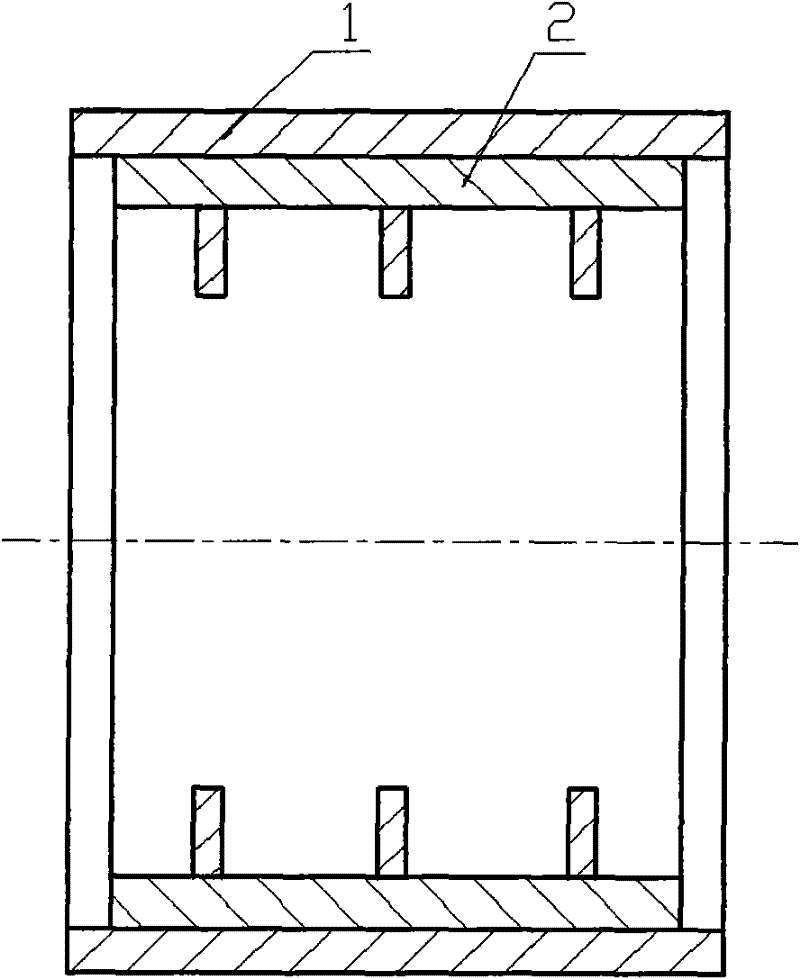

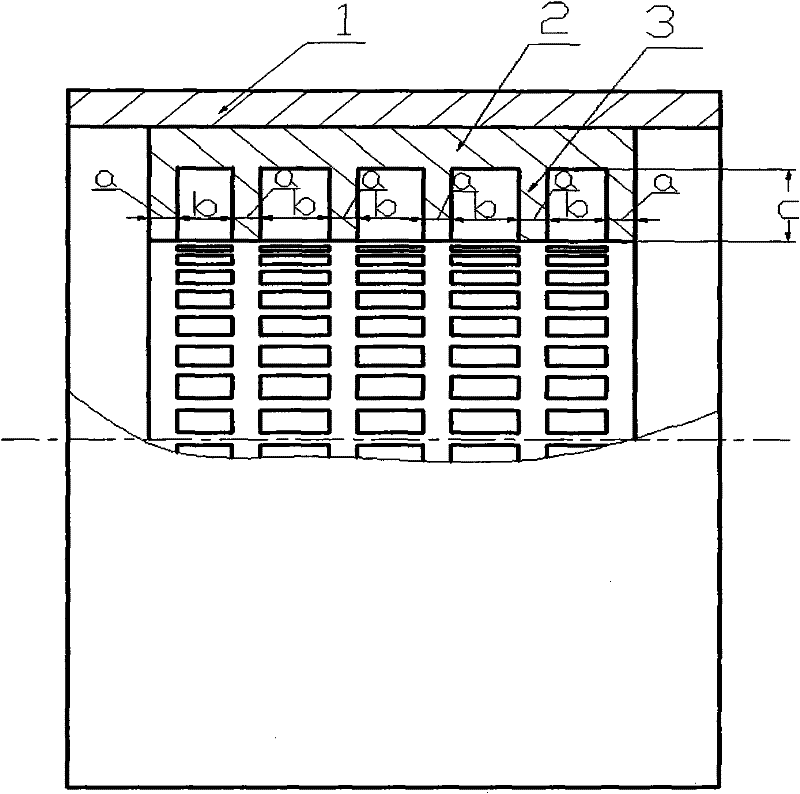

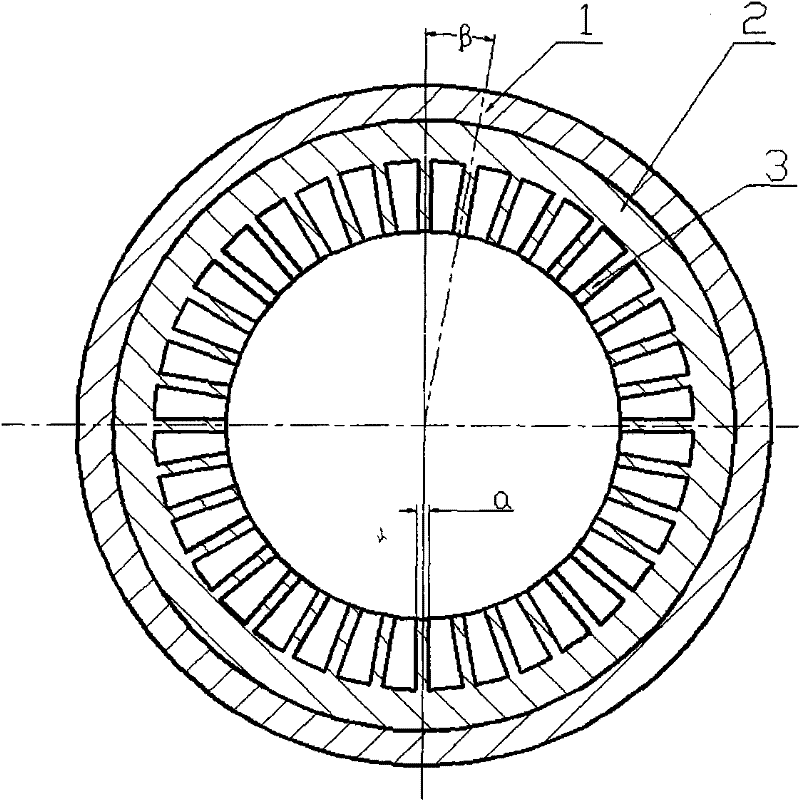

[0019] A rotating cathode roller for electrolysis, comprising an outer cylinder 1, an inner cylinder 2 and a conductive plate 3. The outer diameter of the drum is φ2700mm, and the maximum conduction current is 60KA.

[0020] Such as Figure 2 ~ Figure 4 shown. After the outer surface of the inner cylinder 2 and the inner surface of the outer cylinder 1 are machined and silver-plated, they are shrink-fitted to form a rotating cathode roll for electrolysis. The inner surface of the inner cylinder 2 is distributed with mesh-shaped conductive plates 3 .

[0021] The outer cylinder 1 is a thin-walled cylinder made of pure titanium TA0. The wall thickness of the outer cylinder 1 is 8 mm; the inner diameter of the outer cylinder 1 is 3 mm smaller than the outer diameter of the inner cylinder 2, and fits in an interference manner. The expansion rate of the pure titanium used in the outer cylinder 1 is 10.6×10 -6 (1 / °C).

[0022] The inner cylinder 2 is a thin-walled cylinder cas...

Embodiment 2

[0026] A rotating cathode roller for electrolysis, comprising an outer cylinder 1, an inner cylinder 2 and a conductive plate 3. The outer diameter of the drum is φ2020mm, and the maximum conductive current is 35KA.

[0027] Such as Figure 2 ~ Figure 4 shown. After the outer surface of the inner cylinder 2 and the inner surface of the outer cylinder 1 are machined and silver-plated, they are shrink-fitted to form a rotating cathode roll for electrolysis. A mesh-shaped conductive plate 3 is distributed on the inner surface of the inner cylinder 2 .

[0028] The outer cylinder 1 is a thin-walled cylinder made of pure titanium TAO. The wall thickness of the outer cylinder 1 is 8mm; the inner diameter of the outer cylinder 1 is 2mm smaller than the outer diameter of the inner cylinder 2, and fits in an interference manner. The expansion rate of the pure titanium used in the outer cylinder 1 is 10.6×10 -6 (1 / °C).

[0029] The inner cylinder 2 is a thin-walled cylinder cast f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| coefficient of linear thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com