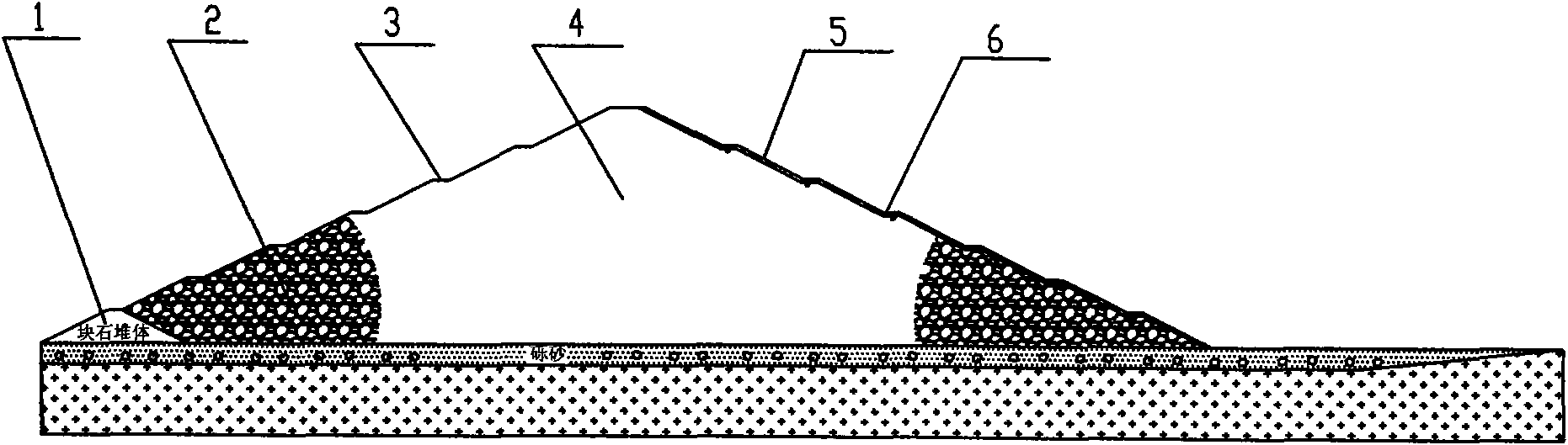

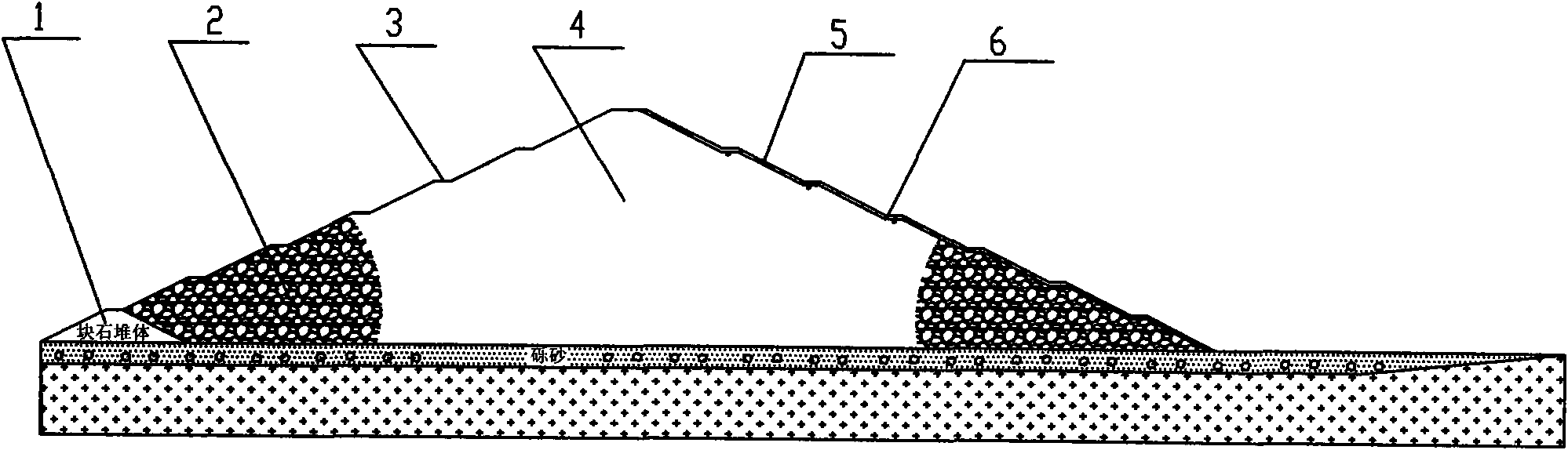

Method for building high roller compaction water-permeable tailing dam by rock dumping

A technology of tailings dam and rock discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0052] Take the concentrator of an iron mine as an example:

[0053] The height of the permeable tailings dam is 144 meters.

[0054] The parameter cohesion is 5MPa.

[0055] The said parameter internal friction angle is 36°.

[0056] The stated dry bulk density is 2.2g / cm 3 .

[0057] The invention effectively combines the mine dump and the tailings pool of the ore dressing plant, which can improve the utilization rate of the existing land in the mine, further increase the volume of the mine dump, solve the problem of insufficient volume of the dump in the long-term mining of iron mines, and reduce The newly acquired land area of the dump site can also increase the volume of the tailings pond and prolong the service life of the tailings pond. Its economic benefits: Taking the tailings dam of a concentrator of an iron mine as an example, the present value of economic benefits of the project during the entire calculation period is 4,941.56 million yuan, and the annual ave...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Average density | aaaaa | aaaaa |

| Average density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com