Remote pumping system for cisterns

a remote pumping and cistern technology, applied in the direction of pumping plants, machines/engines, transportation and packaging, etc., can solve the problems of inconvenient re-use of water, and insufficient volume necessary to salvage burning objects, etc., and achieve the effect of avoiding human and mechanical failures with an undesirable frequency, physical limitation of the proximity of the tank to the drafting apparatus, and avoiding the effect of wasting water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The following description of the preferred embodiment(s) is merely exemplary in nature and is in no way intended to limit the invention, its application, or uses.

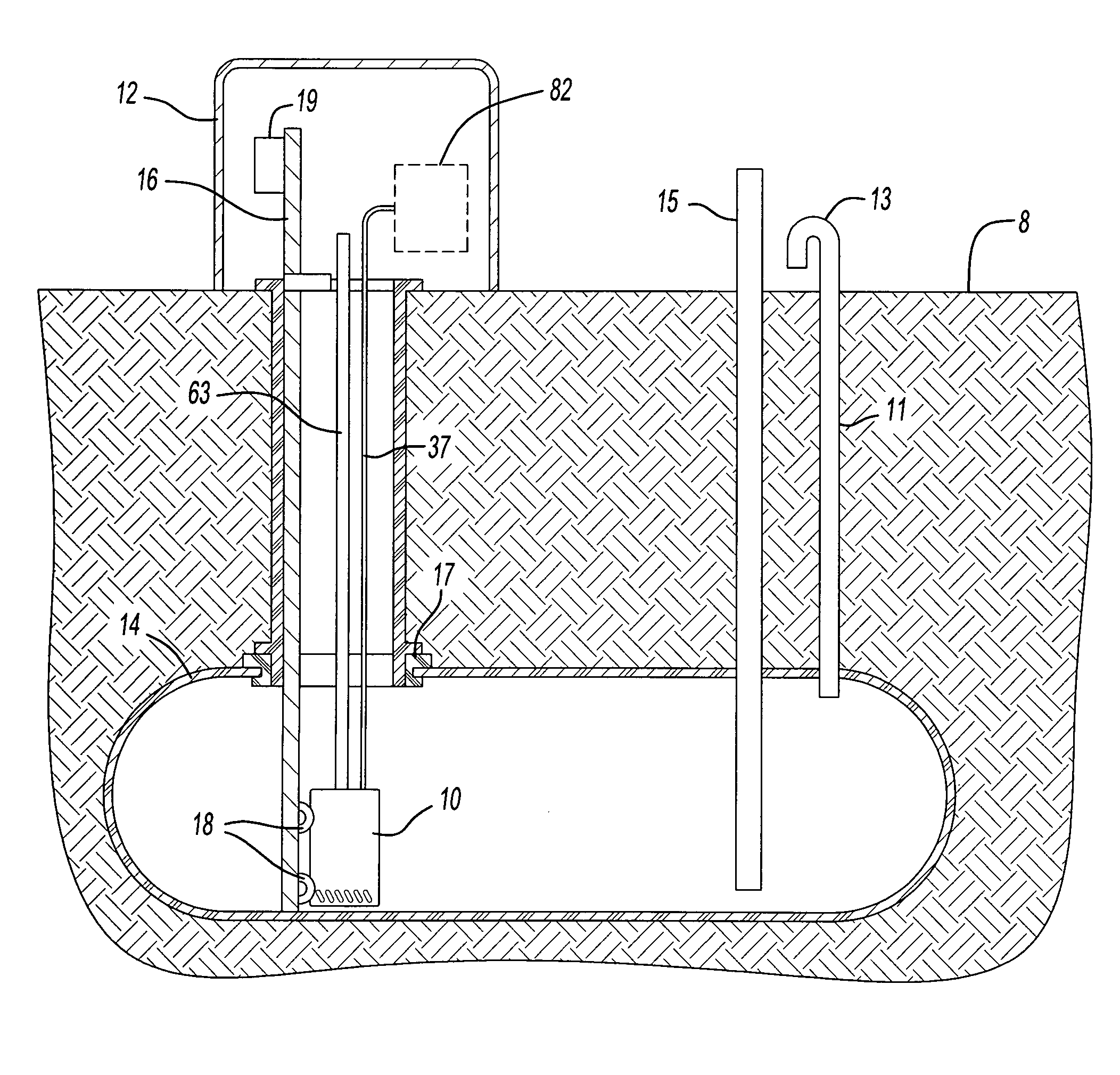

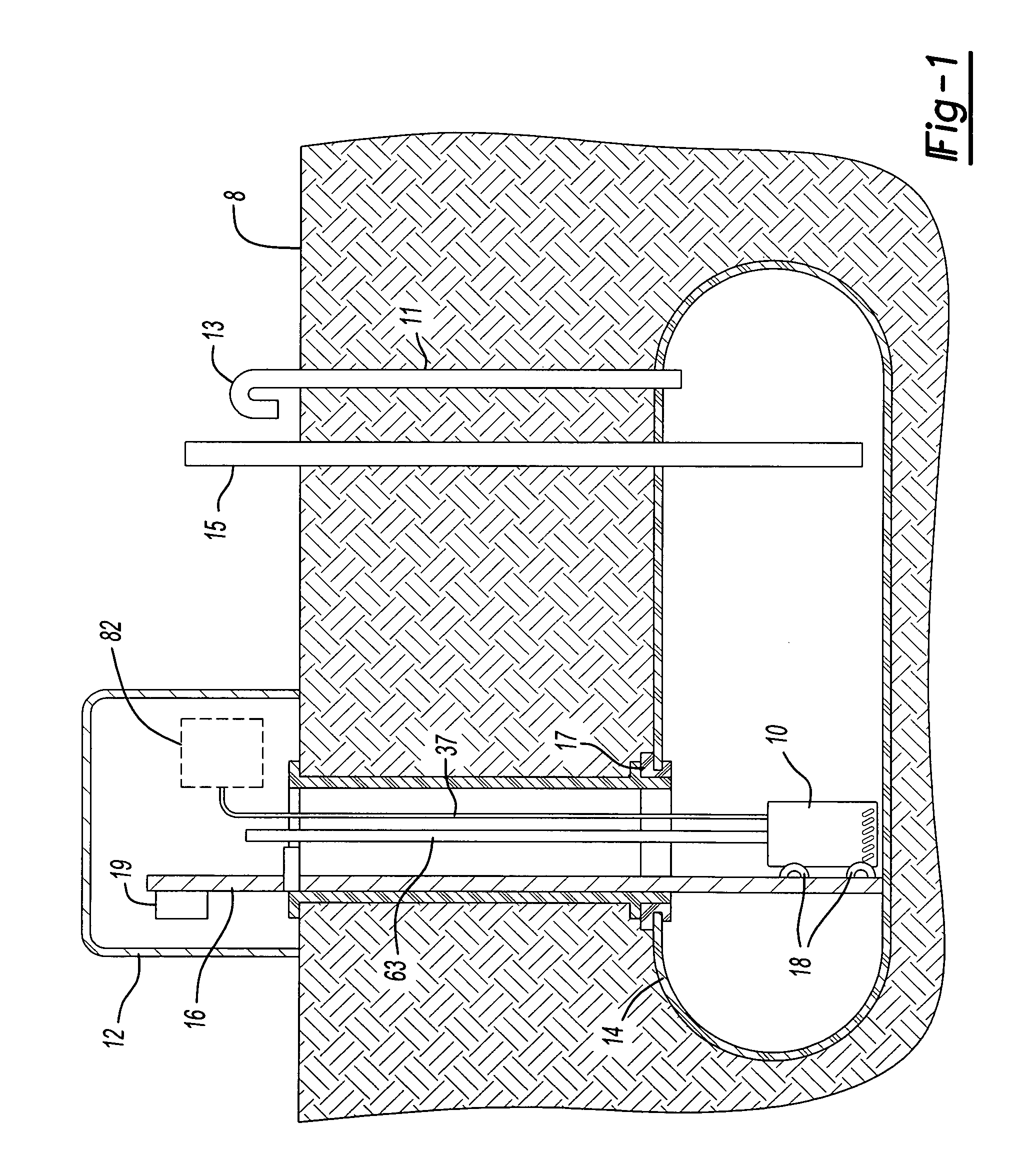

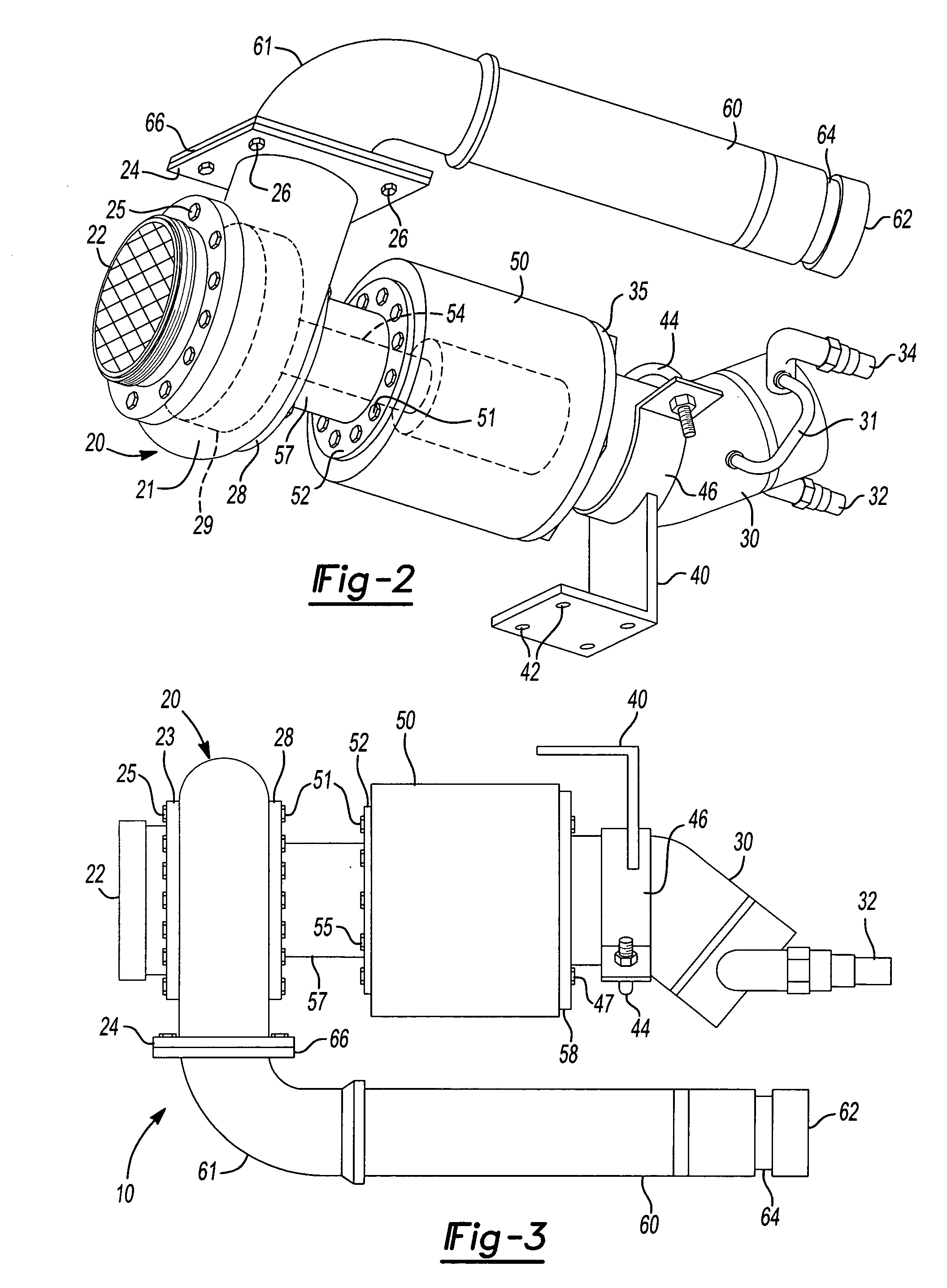

[0024]Referring now to the figures, in particular FIG. 1 the overview schematic of the remote pumping system for use in conjunction with a cistern 14 or water storage vessel is shown. In some embodiments, the water storage vessel or cistern 14 can include any water storage vessel that can be built for storage of water for various purposes commonly encountered, for example, in rural or urban locations. One such purpose is for the storage of water for fire fighting applications, for storage of potable water and the like. In general, the cistern 14 or water storage vessel can be any water containment device and can include a pond, a pool, a portable basin, a municipal hydrant, or a cistern capable of holding from about 10,000 L to about 100,000 L. In some embodiments, the cistern 14, commonly found buried below the groun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com