Lock

A lock head and lock cylinder technology, which is applied to building locks, lock shells, cylinder pin locks, etc., can solve problems such as cramped layout of parts, damage to the overall strength of the lock cylinder, and unfavorable service life of the lock head, so as to improve the overall strength , the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

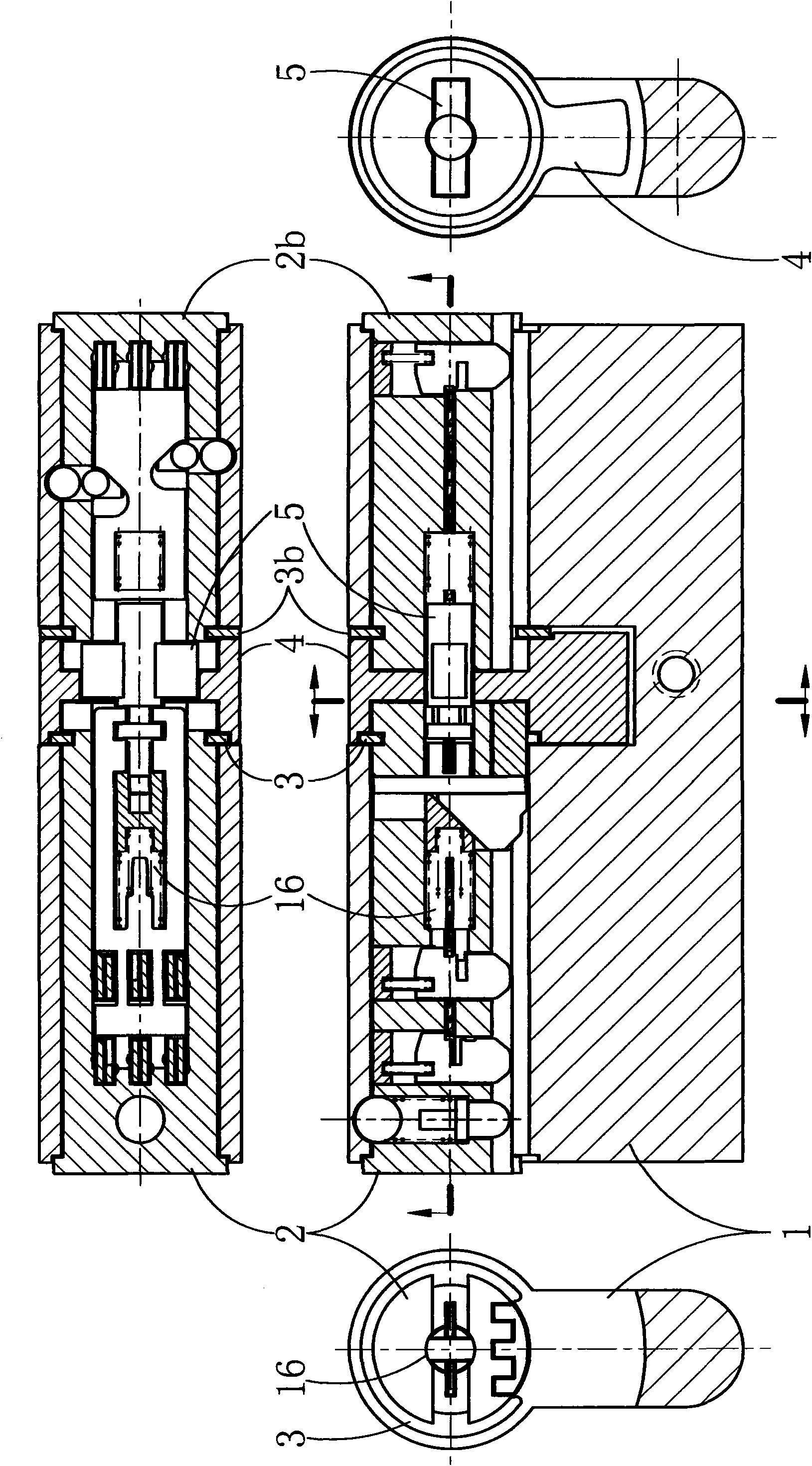

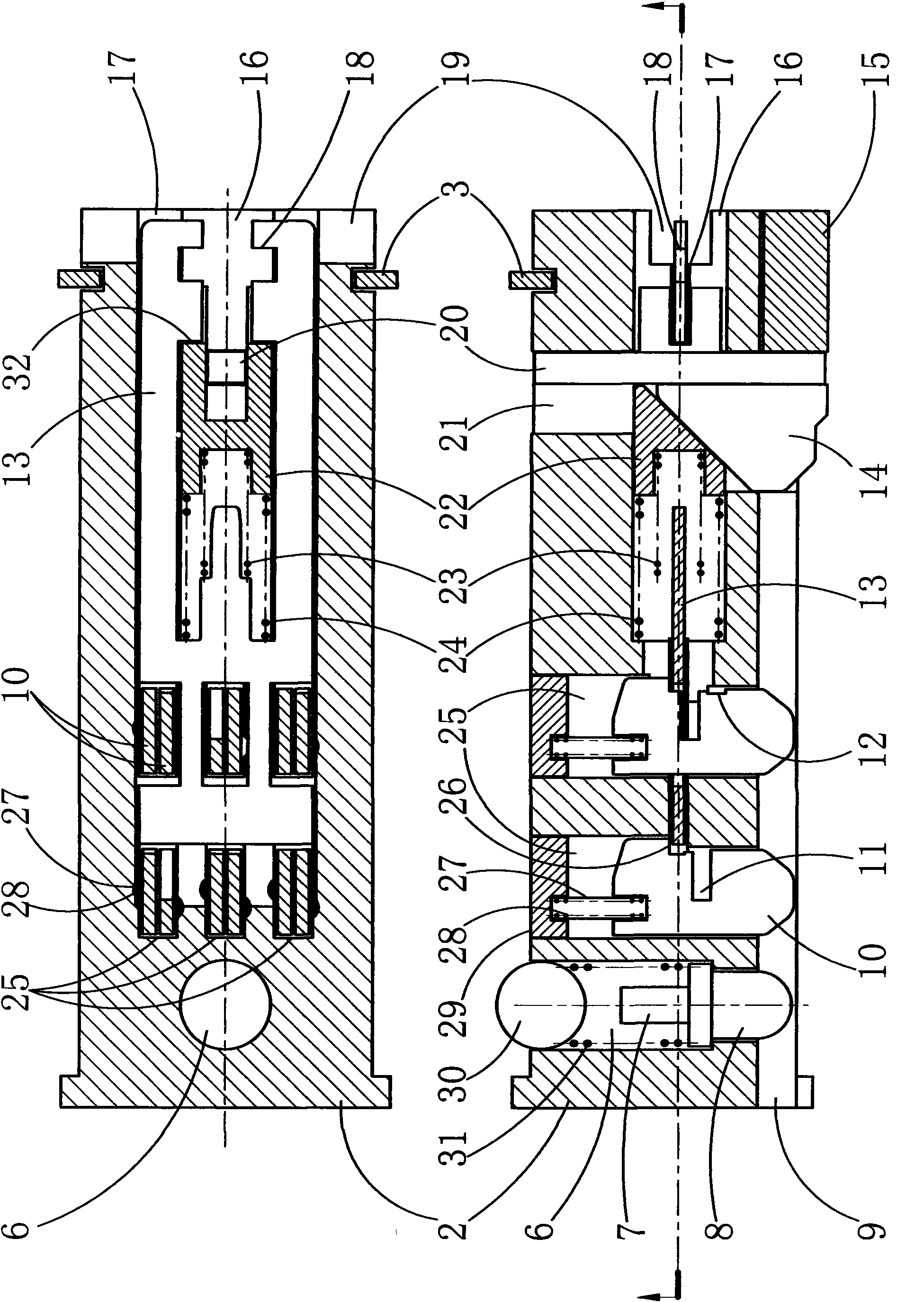

[0030]The outer door lock cylinder in this embodiment adopts an axial normally open code disc, a key drive device including a wire tooth key, and a pull-on clutch bolt, and is equipped with an anti-misoperation device; the door inner lock in this embodiment The lock cylinder adopts an axially normally open code discriminator and a beaded lock cylinder pin (the beaded lock core pin is also used as a driving device—a twisting drive device for an axially normally open code discriminator); in this embodiment The outer door lock cylinder in the door and the inner marbles in the door inner lock cylinder are arranged radially.

[0031] see first figure 1 and figure 2 , the lock body 1 is respectively provided with the door outer lock core 2 and the door inner lock core 2b, which are respectively blocked by the snap ring 3 and the snap ring 3b so that they cannot be drawn out from the lock body. In the middle part of lock body, be provided with dial 4 between the outside lock cyli...

Embodiment 2

[0035] In the present embodiment, a camouflage identification chip for improving the difficulty of technical opening is arranged in the lock cylinder. see Figure 10 , the camouflaged code identification sheet 13c and the code identification sheet 13 are installed side by side in the raised chute 17c, the camouflaged code identification sheet is provided with a positioning hook 32c, and the outer ring of the code identification push spring 23 is provided with a propelling spring for the camouflaged code identification sheet 23c, due to the effect of the positioning hook 32c and the propelling spring 23c of the fake code identification piece, the fake code identification piece 13c can move back and forth along the axis of the lock cylinder following the central slide block 22. As can be seen from the figure, when the key for technical opening or insertion is not the key of the lock, the identification code piece 13 and the fake code identification piece 13c will be respectively...

Embodiment 3

[0037] The lock head in this embodiment adopts an axially normally open code discriminator, a twisting drive device and a rigid lock cylinder pin; the inner pins in this embodiment are arranged radially.

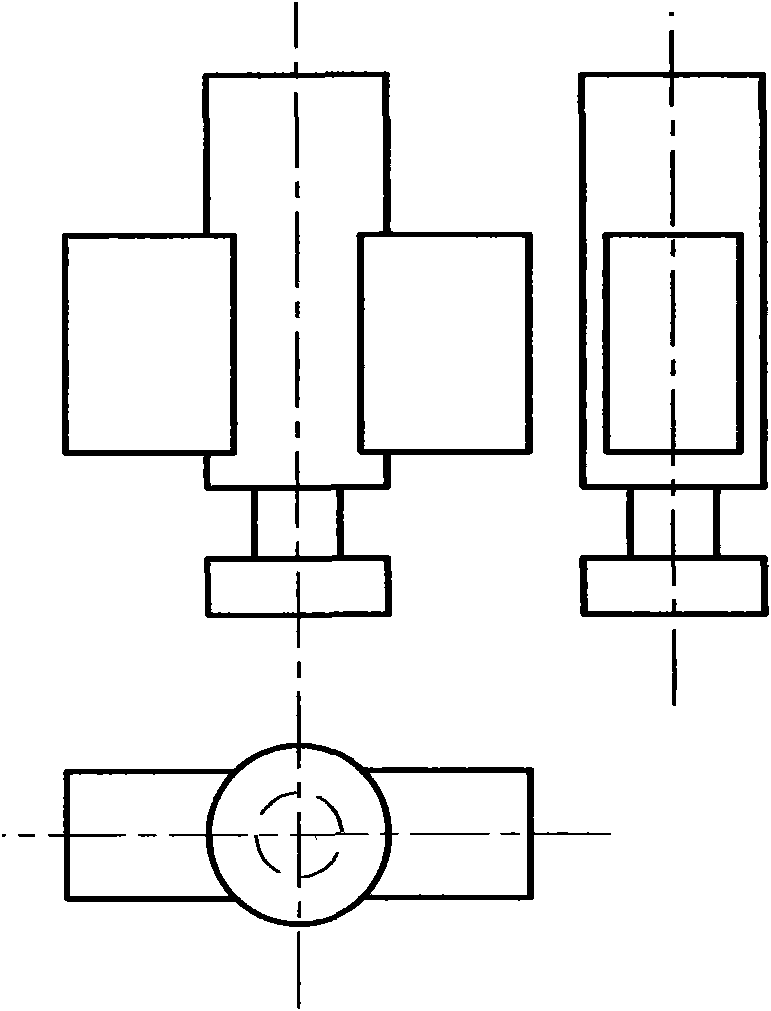

[0038] see Figures 11 to 13 , In this embodiment, a torsion driving device composed of a push-pull plate 41 and a steel ball 40 is provided. A lock core 2d is provided in the lock body 1d, and a snap ring 3d prevents the lock core 2d from being pulled out from the lock body. Inner pins 10d arranged radially are arranged in the lock cylinder 2d. A code identification piece 13d is arranged in the chute coaxial with the lock core, and the above-mentioned push-pull plate 41 is also arranged in the groove. On code identification piece 13d, be provided with linkage hook 42 and lock core pin control piece 45, because the effect of linkage hook 42 and code identification push spring 23d and snap ring 43, code identification piece 13d can follow push-pull plate 41 along the direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com