Floating ball sliding sleeve device of energy accumulator

A technology of accumulators and floating balls, applied in the direction of mechanical equipment, etc., can solve problems such as loss of function and low pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

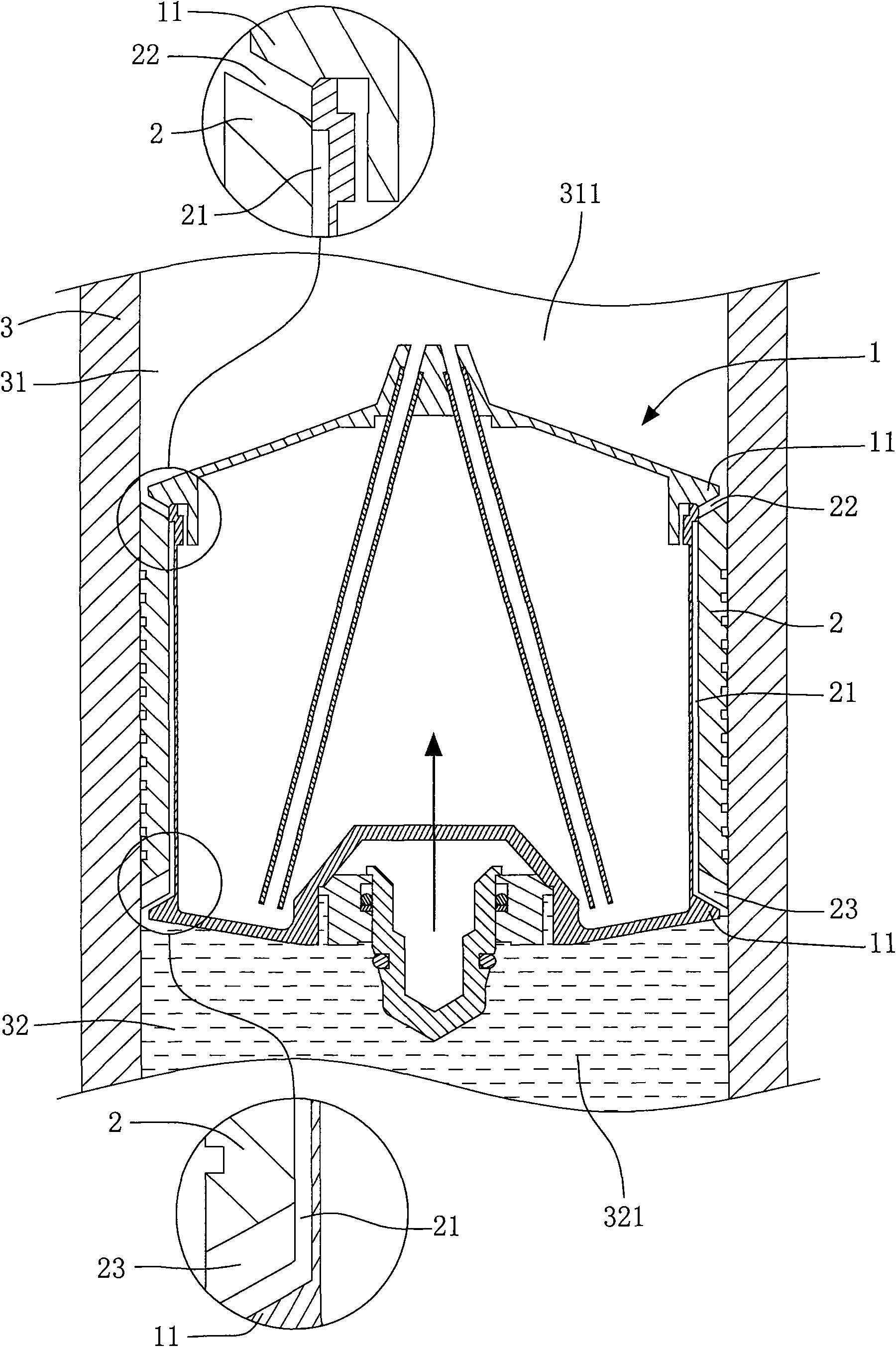

[0022] The above and other technical features and advantages of the present invention will be described in more detail below in conjunction with the accompanying drawings.

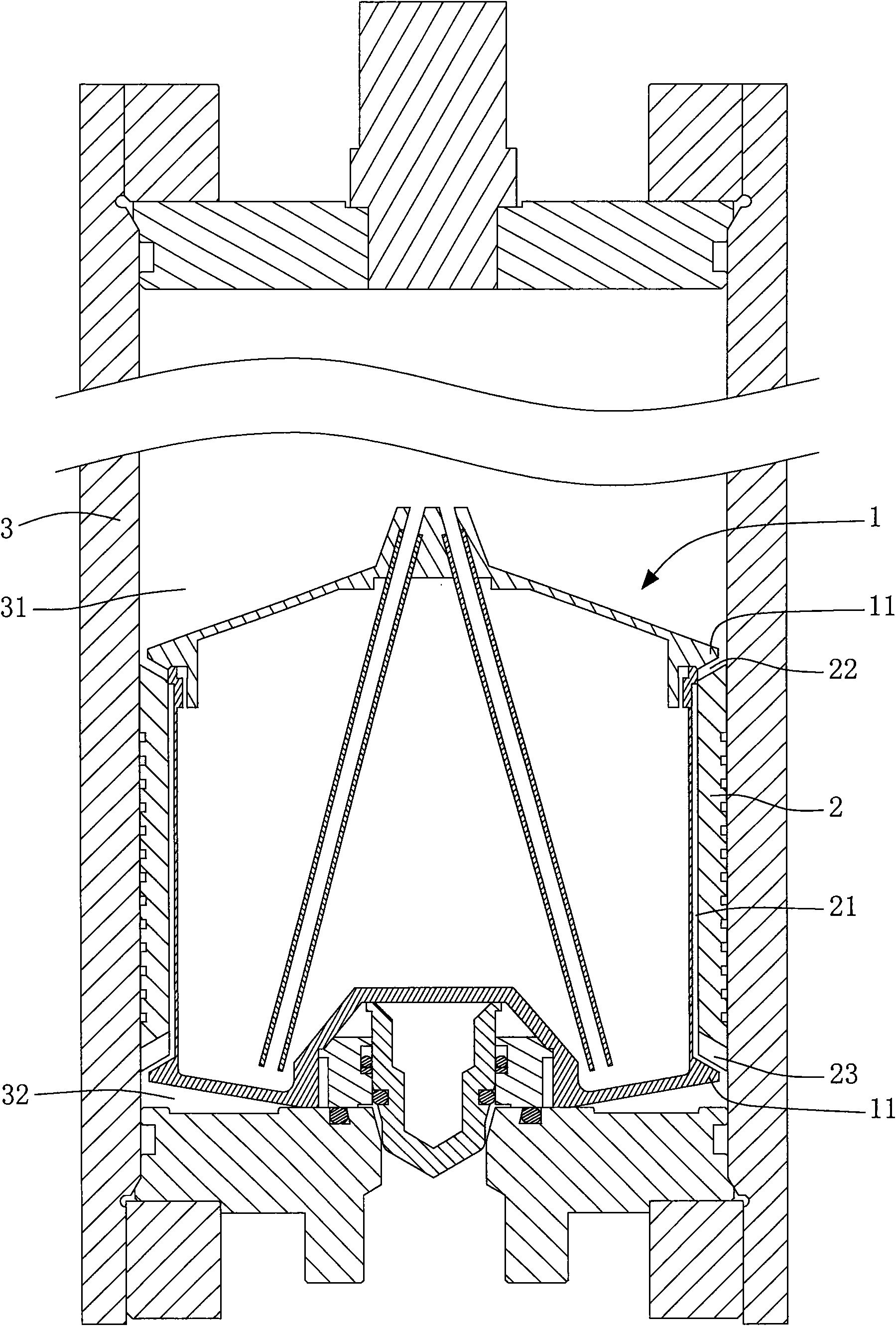

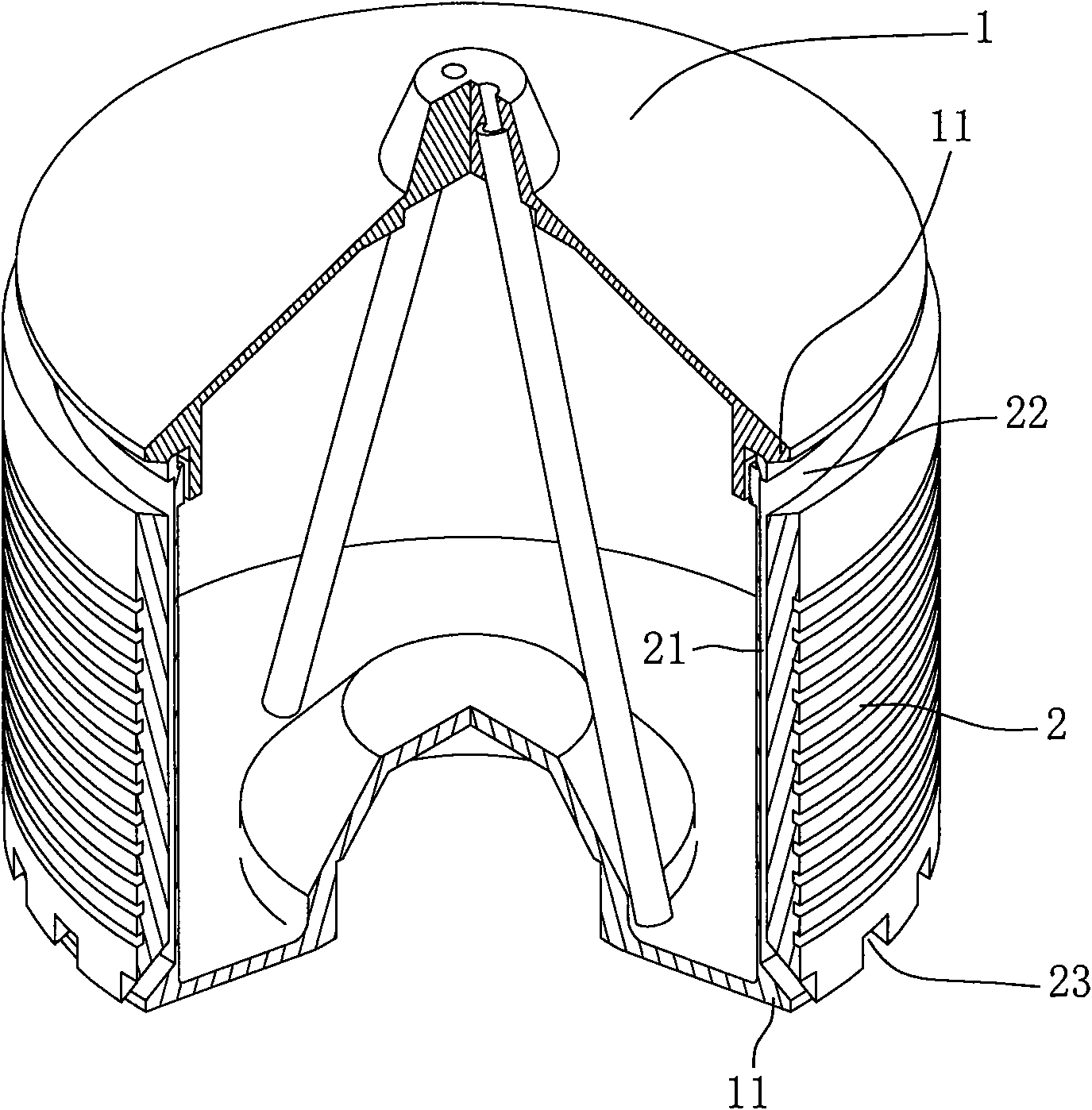

[0023] See first figure 1 and figure 2 As shown, the "accumulator floating ball sliding sleeve device" of the present invention includes a floating ball body 1, a ring sleeve 2 and a cylinder tube 3, wherein:

[0024] The floating ball body 1 is a hollow cylinder, and a ring 11 protrudes from its upper and lower edges.

[0025] The ring sleeve 2 is a ring cylinder combined on the vertical side periphery of the floating ball body 1, and the length of the ring sleeve is shorter than the floating ball body 1 and can slide between the upper and lower ring edges 11 without coming out. There is a gap 21 between the floating ball body 1 and the ring sleeve 2, and an annular upper opening 22 is formed at the upper end of the floating ball body 1 and the ring sleeve 2 to communicate with the gap 21; the lower en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com