Self cleaning grease lubricated spline

A spline and spline tooth technology, used in lubricating parts, engine lubrication, key connections, etc., can solve problems such as increasing the cost and complexity of rotating machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

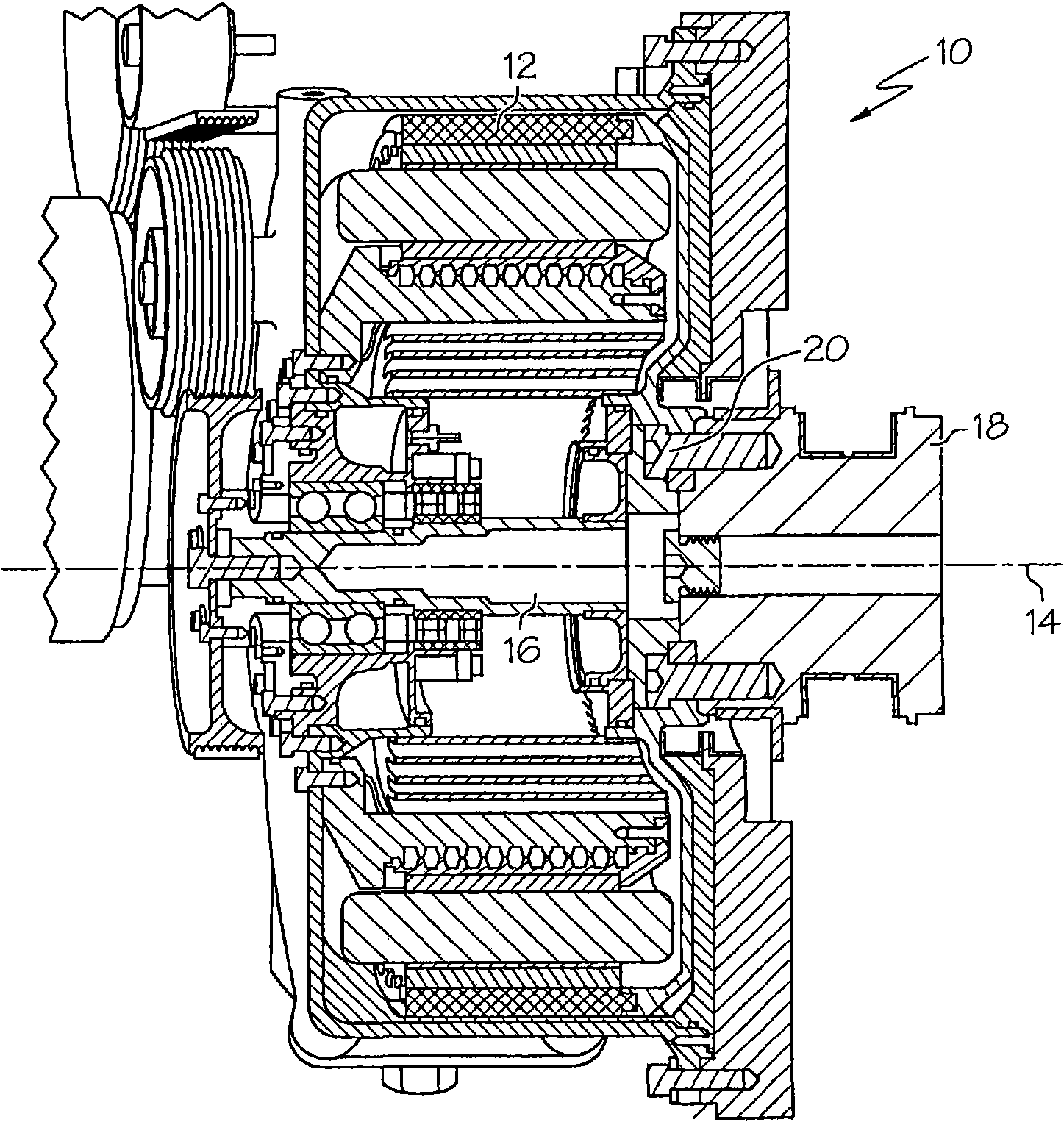

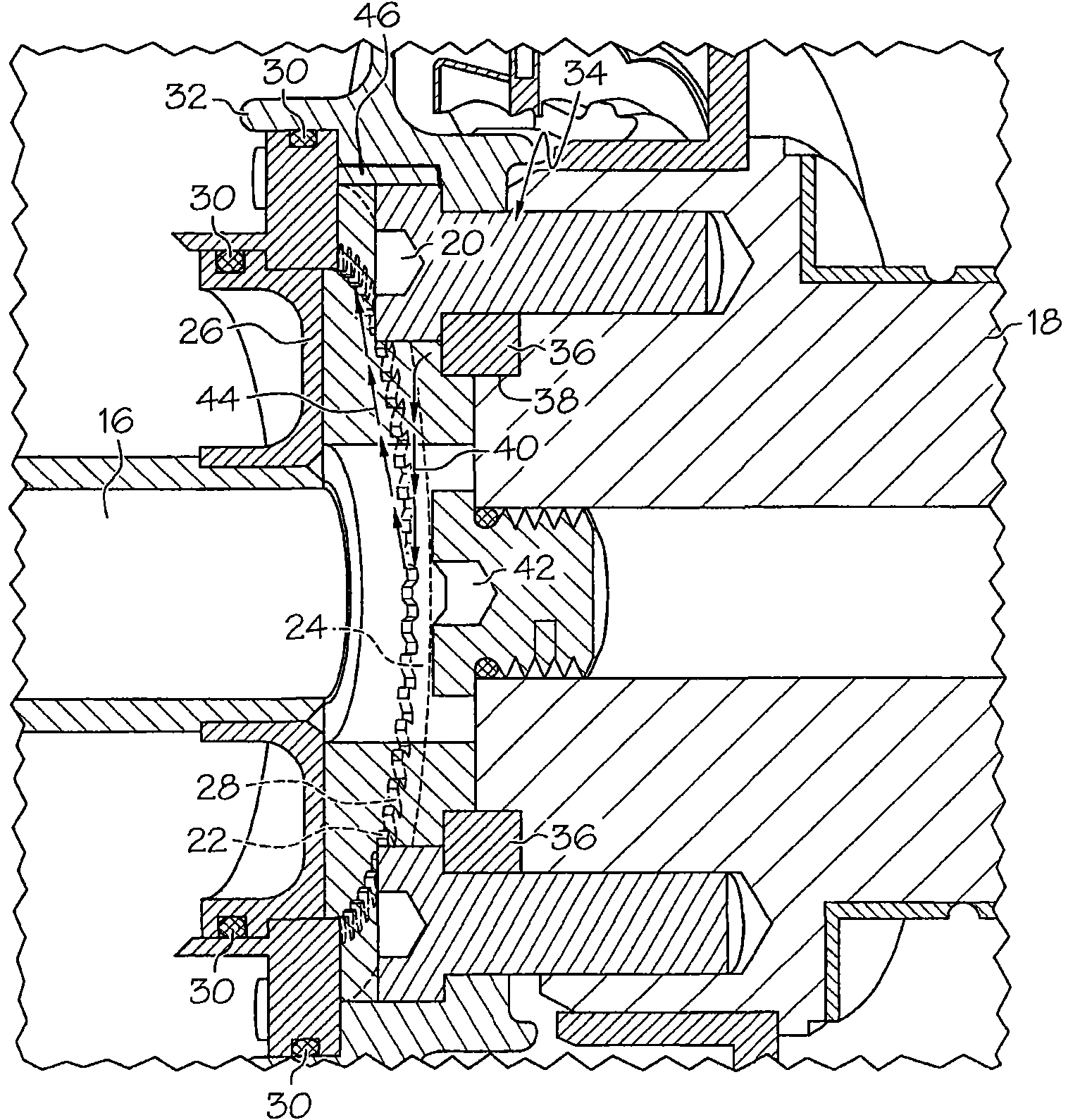

[0011] figure 1 Shown in is a section of a rotating machine, in this case a generator 10 . The generator 10 includes at least one rotor 12 rotatable about a central axis 14 . The electric machine 10 includes a generator shaft 16 disposed at a central axis 14 and connected to, for example, an engine crankshaft 18 via one or more splined interfaces 20 . now refer to figure 2 , in some embodiments, the spline interface 20 is defined by a plurality of generator shaft teeth 22 meshing with a complementary plurality of crankshaft teeth 24 .

[0012] In some embodiments, such as figure 2 As shown, a plurality of generator shaft teeth 22 extend radially inwardly from an inner surface of a substantially annular generator shaft plate 26 which in some embodiments is welded or otherwise secured to the On the generator shaft 16. Also, in some embodiments, a plurality of crankshaft teeth 24 are disposed at and extend radially outwardly from a crankshaft plate 28 . Crank plate 28 may...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com