Three-dimensional micro confocal measuring system and method utilizing optical polarization characteristic

A measurement method and measurement system technology, applied in the field of three-dimensional microscopic confocal measurement system, can solve problems such as the inability to meet the needs of high precision and rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] In order to have a further understanding and understanding of the characteristics, purpose and functions of the present invention, the relevant detailed structure and design concept of the device of the present invention will be explained below, so that the review committee can understand the characteristics of the present invention, in detail The description states the following:

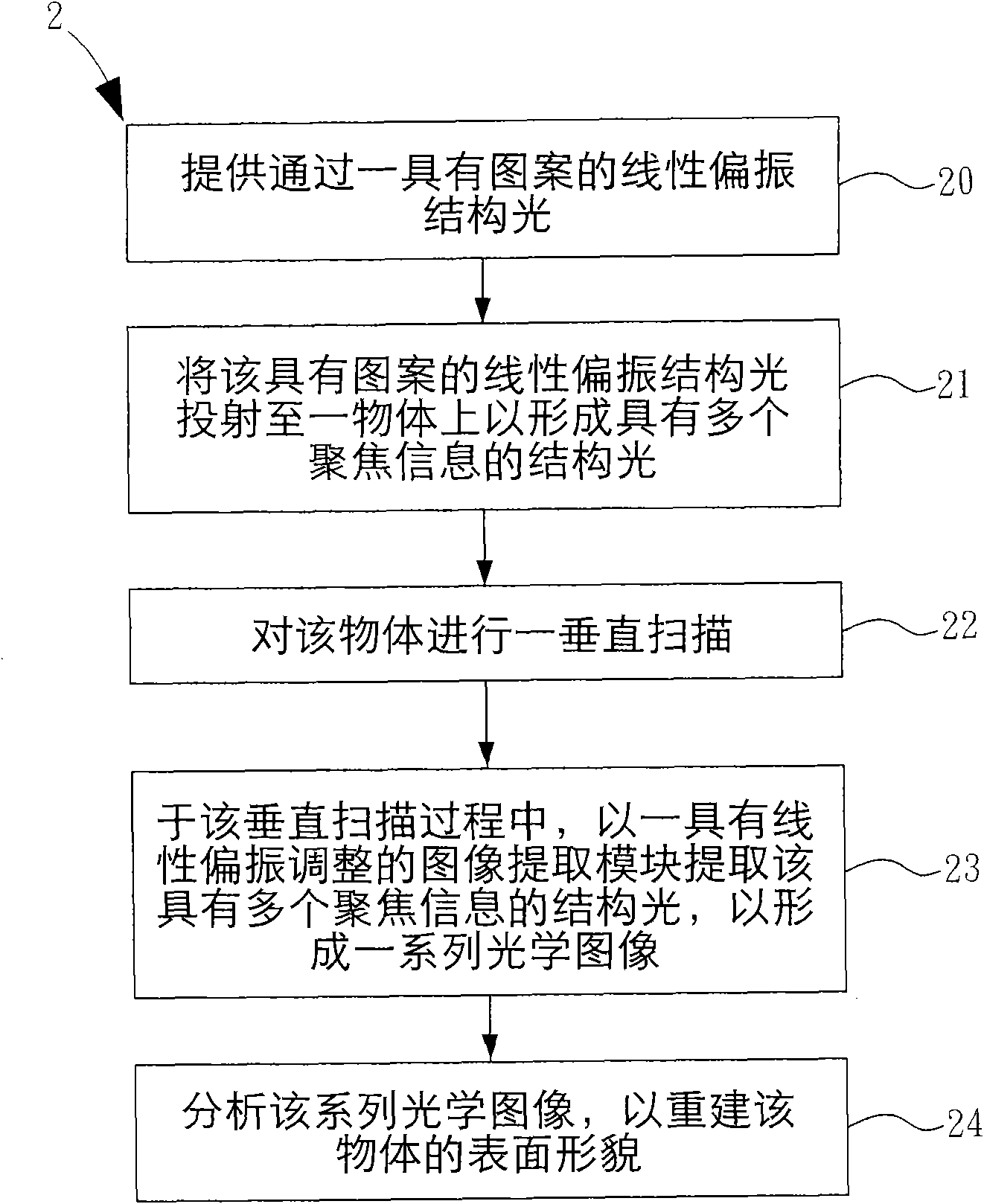

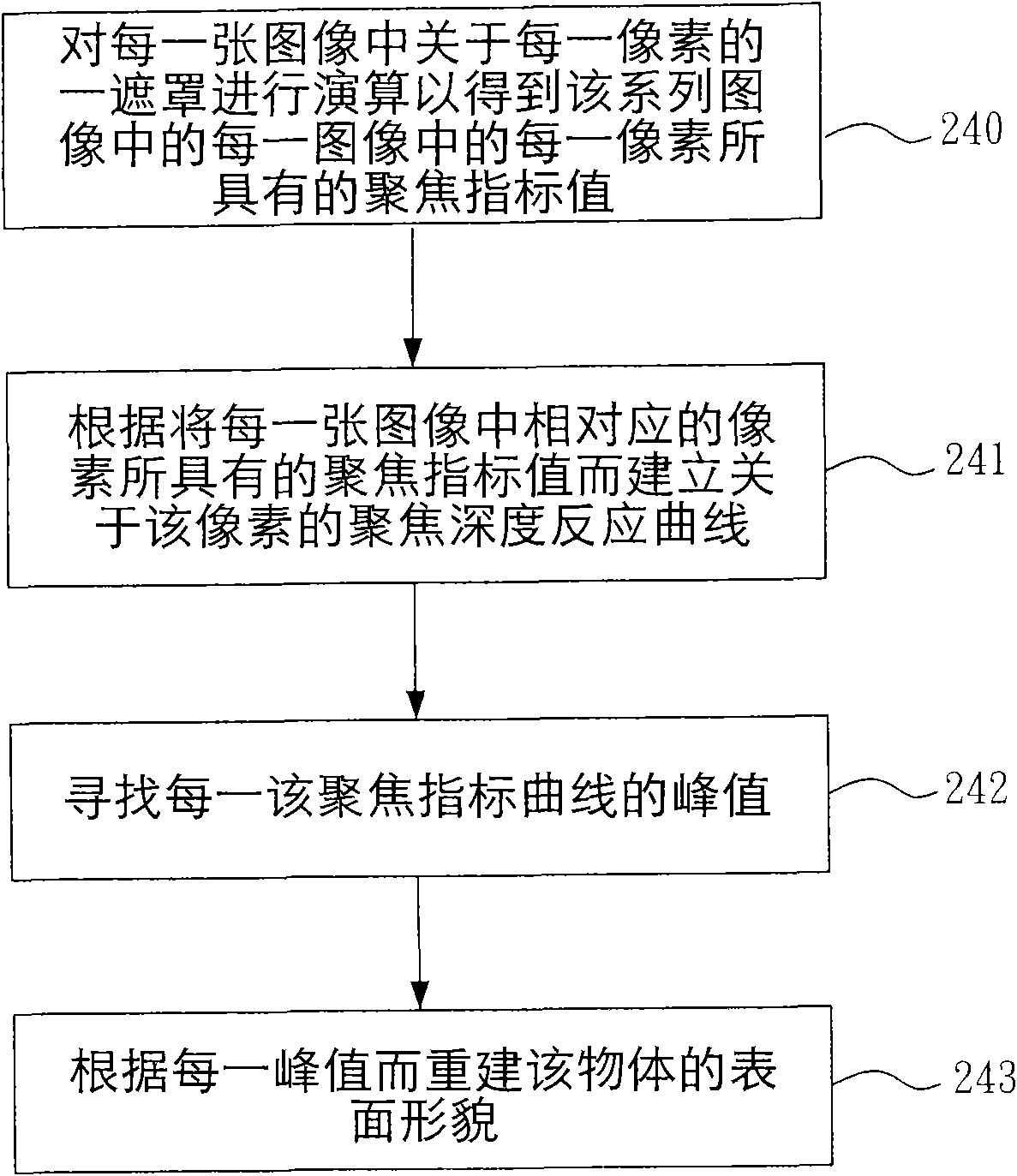

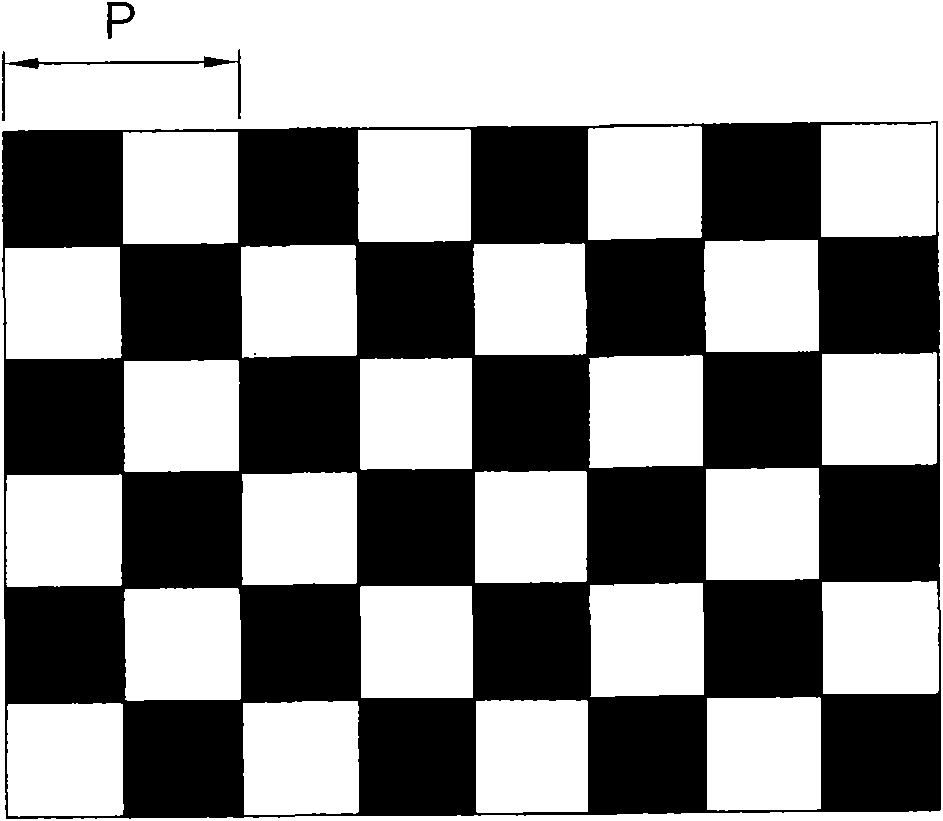

[0068] The invention provides a three-dimensional microscopic confocal measurement system and method, which is aimed at measuring the microstructure surface topography with high transparency and large inclination angle. High-frequency information, combined with the principle of focused shape measurement, is used for global measurement.

[0069]The invention provides a three-dimensional microscopic confocal measurement system and method. When the measurement tilt angle increases, the intensity of reflected light received by the image sensing unit and the contrast of the structured light in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com