Drive method and circuit for Polymer Dispersed Liquid Crystal (PDLC)

A technology of dispersed liquid crystal and driving method, which is applied in optics, instruments, nonlinear optics, etc., can solve problems such as screen flickering, screen flickering and jumping, etc., to eliminate screen flickering, reduce haze, and reduce drive The effect of power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

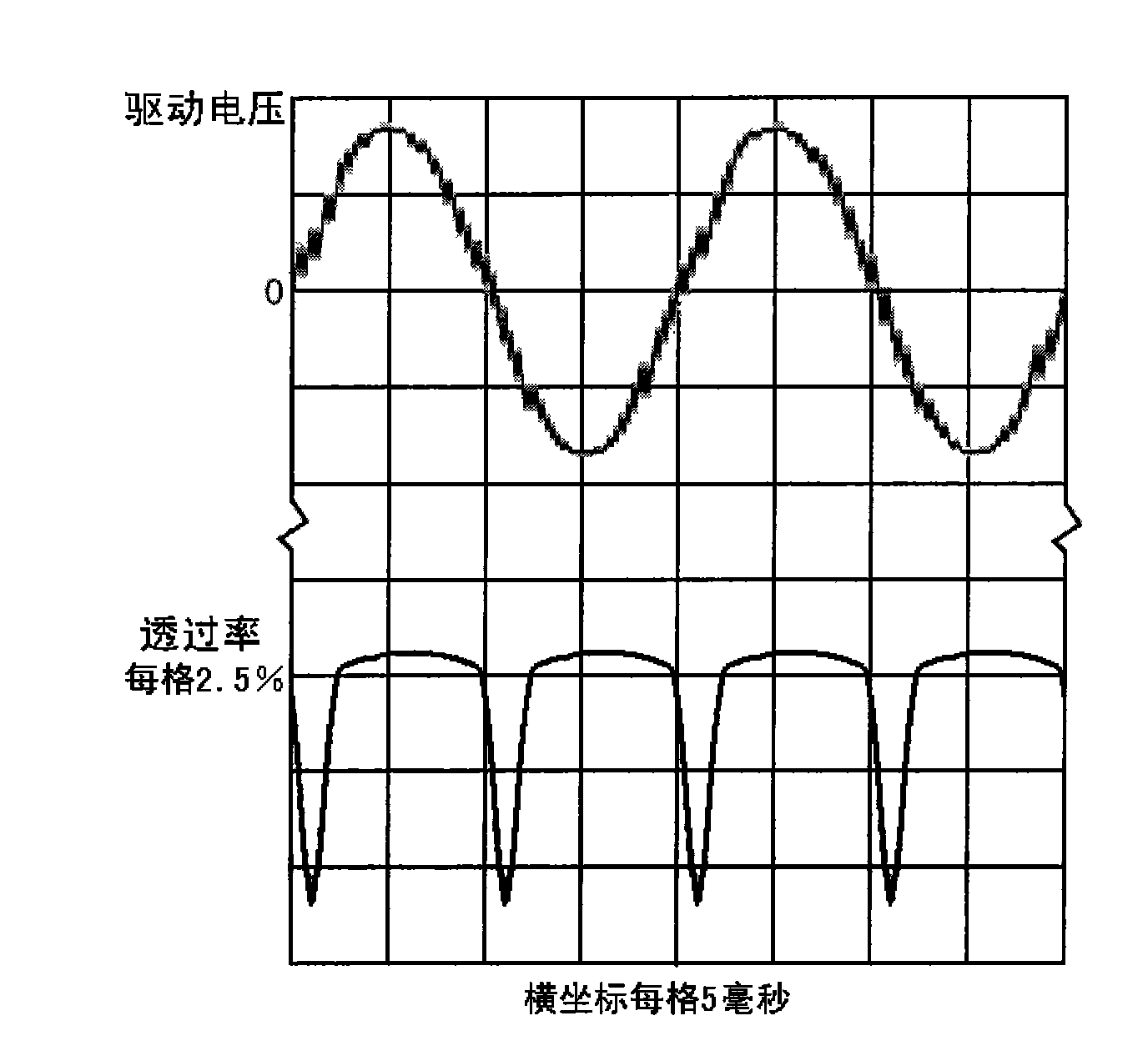

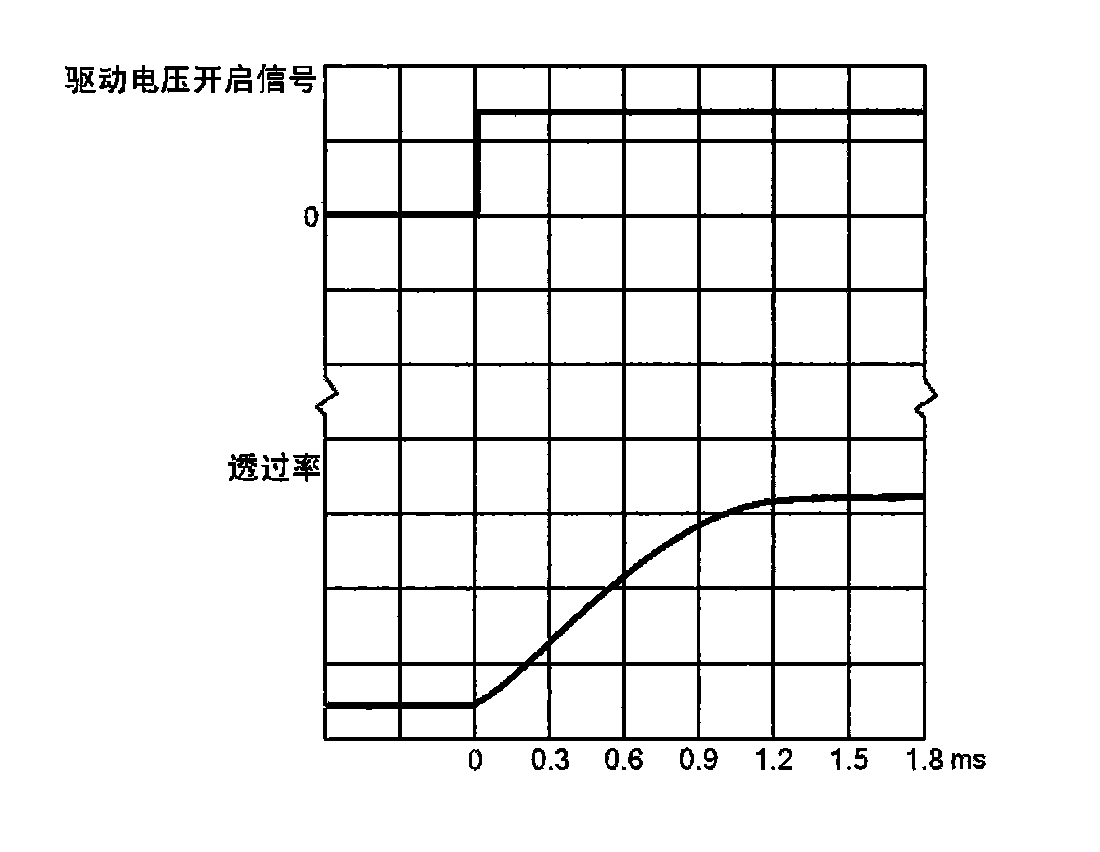

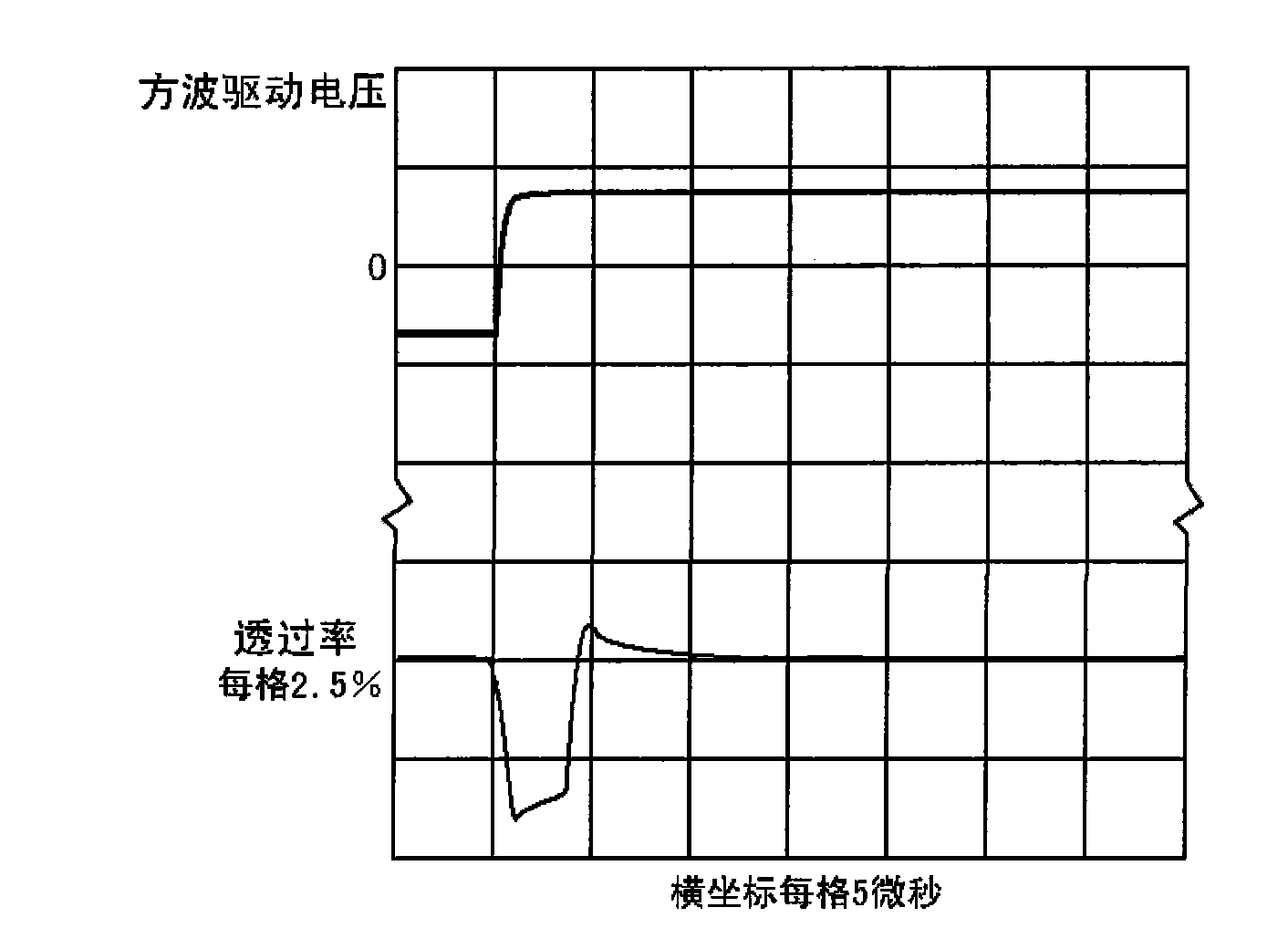

[0021] The driving method of the polymer-dispersed liquid crystal film of the present invention has a driving power supply that is electrically connected to two input electrodes of the polymer-dispersed liquid crystal film, and the voltage waveform that the driving power is applied to the input electrodes of the polymer-dispersed liquid crystal film It is a rectangular wave, and the front and rear edges of the rectangular wave should change rapidly, and its rising and falling time should be much shorter than the response time of opening and closing of the polymer dispersed liquid crystal film.

[0022] The polymer dispersed liquid crystal film of the present invention can be made into dimming glass, magic glass, electroluminescent liquid crystal atomized glass, etc., and the electroluminescent liquid crystal atomized glass in one embodiment of the present invention includes polymer dispersed liquid crystal film For the product, the structure of the electroluminescent liquid cry...

Embodiment 2

[0026] see Figure 4 , Figure 5 , the driving circuit of the polymer dispersed liquid crystal film of the present invention has a driving power source electrically connected to two input electrodes of the polymer dispersed liquid crystal film, and the driving power source includes a rectangular wave generating circuit, a driver stage, a double-arm bridge push-pull output circuit; the double-arm bridge push-pull output circuit includes four field effect transistors or insulated gate bipolar transistors; wherein the drain of the field effect transistor T1 is electrically connected to the positive pole of the power supply, and the source of the transistor T1 is connected to the transistor T2 The drain is electrically connected, the source of the transistor T2 is connected to the power ground; the drain of the transistor T3 is electrically connected to the positive pole of the power supply, the source of the transistor T3 is electrically connected to the drain of the transistor T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com