Four-claw large pipe chuck

A chuck, large-scale technology, applied in the direction of chuck, clamping, support, etc., can solve the problems of lack of multiple compound clamping means, single chuck clamping means, low processing efficiency, etc., and achieve rich clamping. means, reducing labor intensity, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

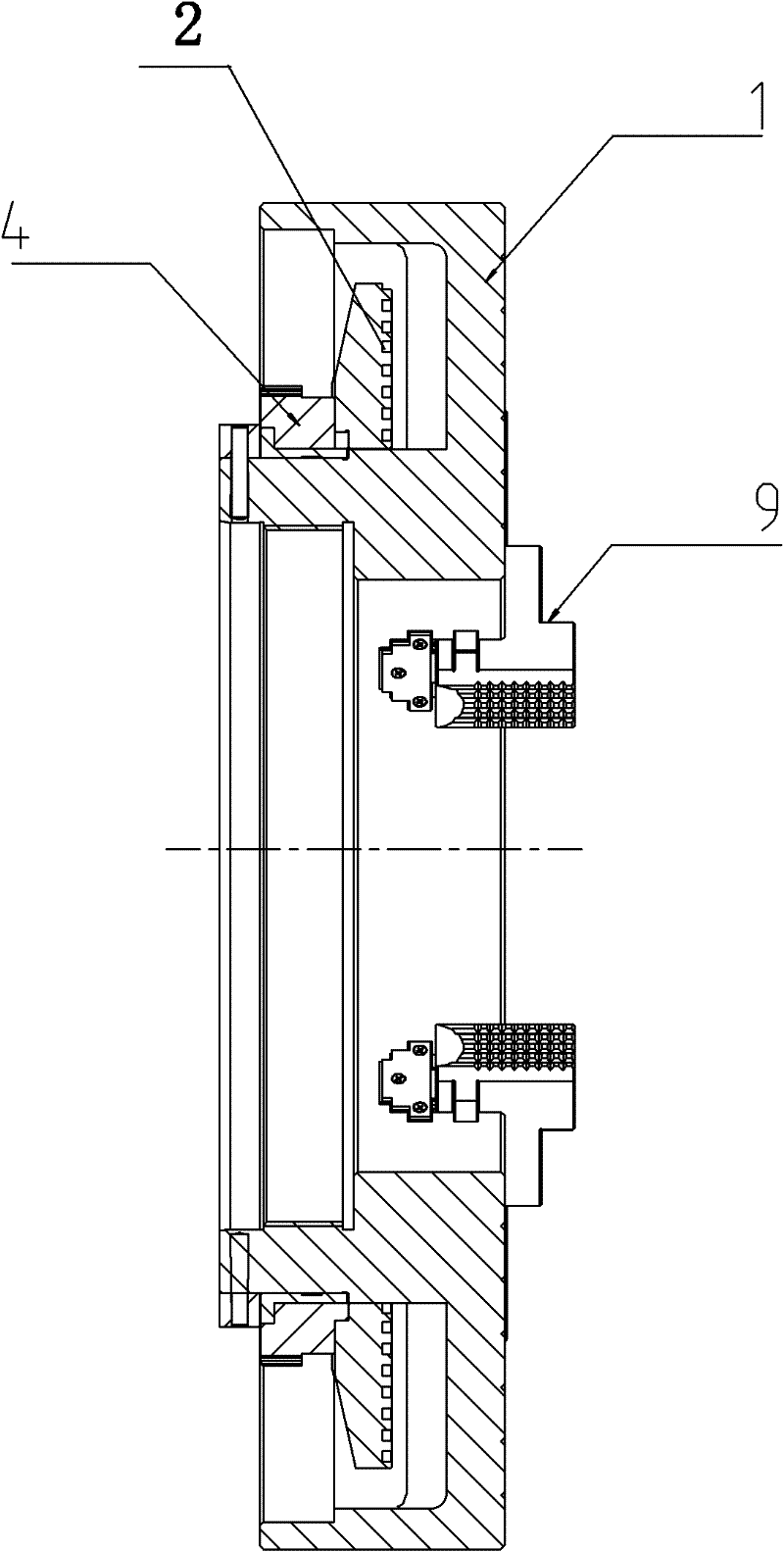

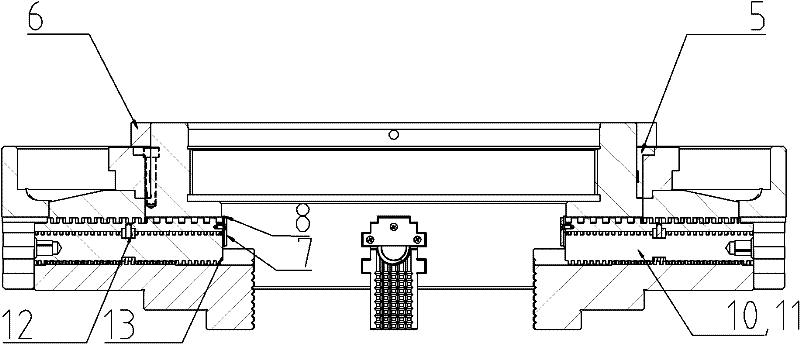

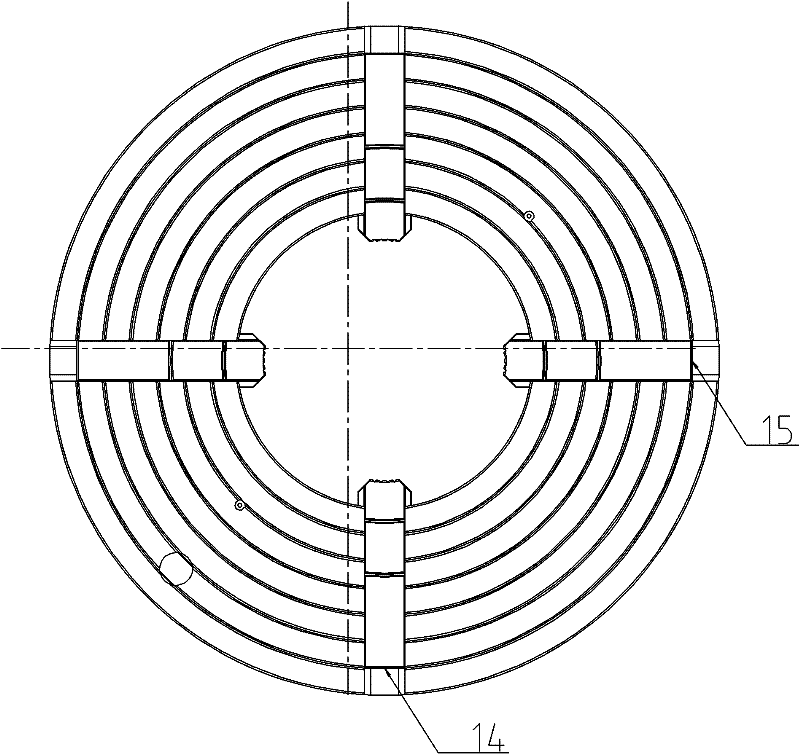

[0014] Such as Figure 1 ~ Figure 2 Shown: including chuck body 1, coil wire 2, gear 4, copper sleeve 5, retaining ring 6, cover plate 7, pad 8, four claws 9, first slide 10, second slide 11, four A block 12, four screw 13, the third slide 14, the fourth slide 15, etc.

[0015] The gear 4 of the present invention is embedded in the rear portion of the chuck body 1, and is fastened with the coil wire 2 by screws. The coil wire 2 is fixed in the inner cavity of the chuck body 1 and connected with the gear 4 through screws. The retaining ring 6 is in interference fit with the inner hole of the gear, and is installed in the gear 4 to play a position-limiting role. The copper sleeve 5 is in interference fit with the retaining ring inner hole, is installed in the retaining ring 6, and is installed in cooperation with the machine tool spindle to prevent we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com