Construction method of dewatering well in underground concrete structure

A technology of concrete structure and construction method, which is applied in the direction of basic structure engineering, construction, etc., can solve the problems that the sealing concrete does not reach the strength, the new and old concrete are not tightly connected, and the structure leaks, etc., so as to avoid structural leakage, reduce groundwater pressure, and seal treatment. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

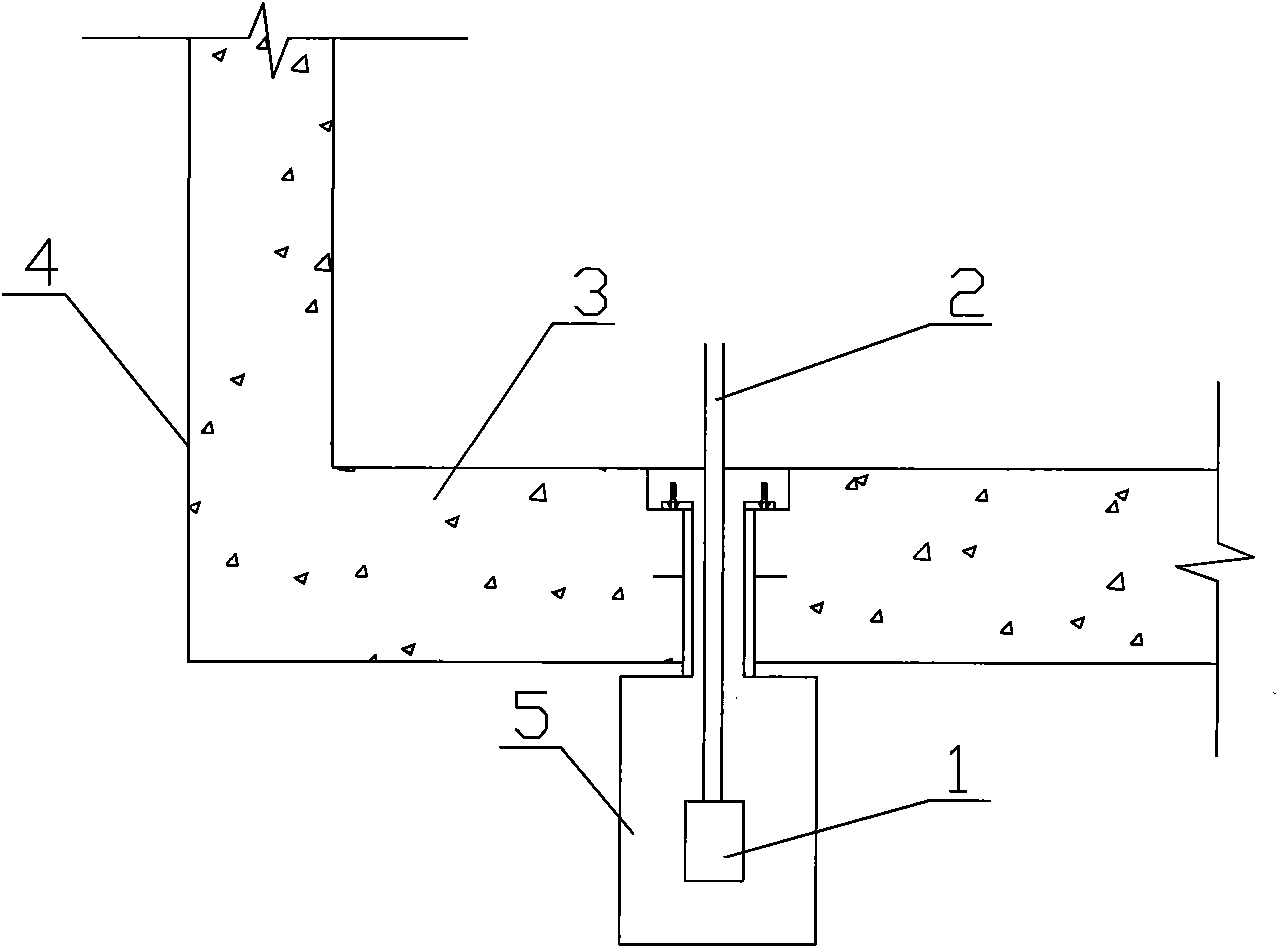

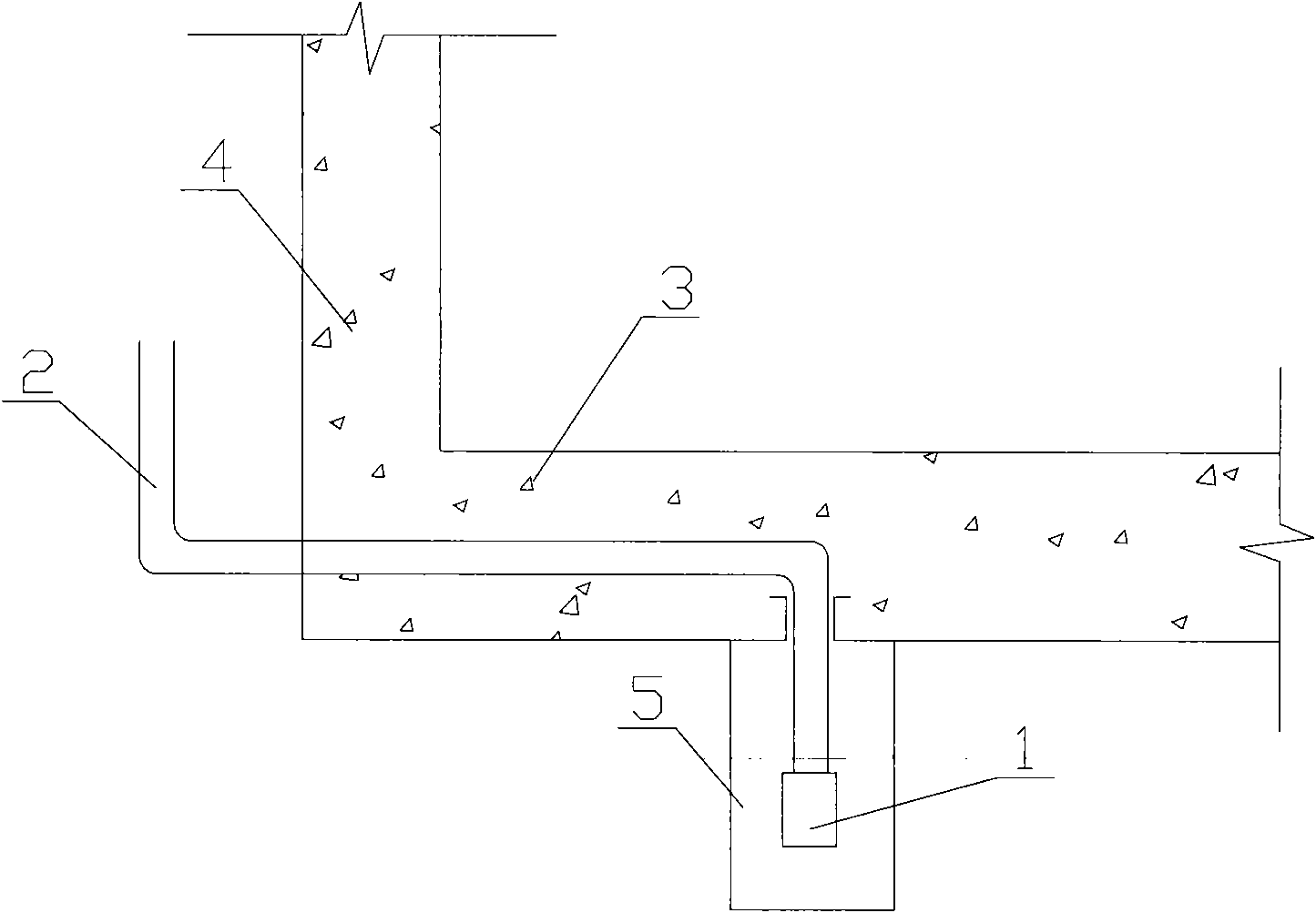

[0036] Such as figure 2 As shown, when the building adopts an underground independent wall, that is, when there is a certain space between the outside of the wall and the foundation pit, the outside of the underground concrete structure can support formwork. Firstly, the foundation pit is sloped and excavated, and a dewatering well 5 is set at the bottom of the foundation pit. A downwater pipe 2 is arranged in the dewatering well 5, and the lower port of the downwater pipe 2 is connected to the water pump 1, and the upper port of the downwater pipe 2 is led out along the inside of the concrete bottom plate 3 to be poured to one side until the outer side of the concrete bottom plate 3 and the foundation pit In the space, it extends upward along the foundation pit to a place higher than the groundwater level. During the derivation process, the downcomer 2 should follow the optimal path, and the so-called optimal path is the shortest path under the premise of bypassing obstacle...

Embodiment 2

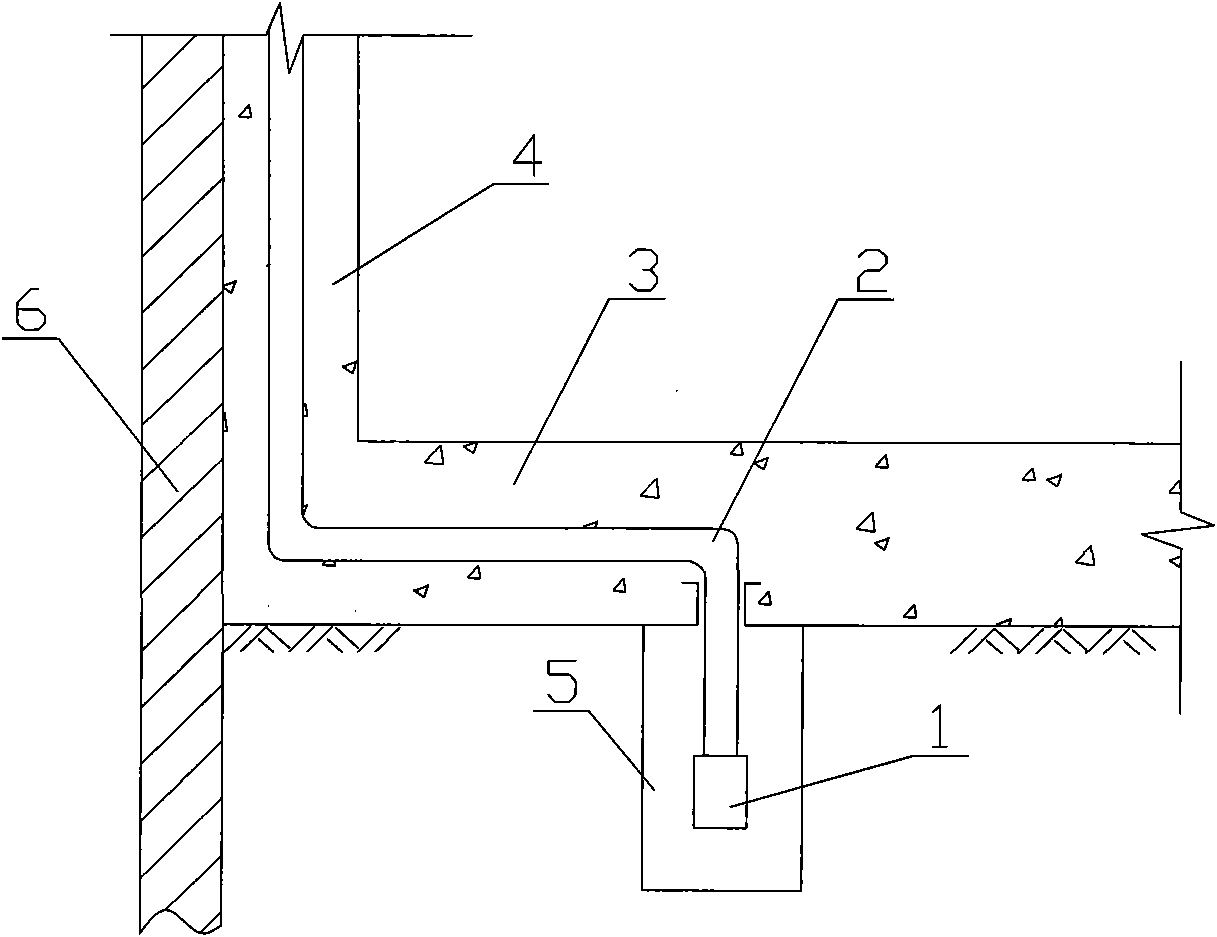

[0040] Such as image 3 As shown, when the building is supported by an underground diaphragm wall or cantilever piles, and one side of the inner wall of the underground concrete structure supports the formwork, the underground concrete side wall 4 is connected to the support structure 6, and the situation of the above-mentioned embodiment 1 is not applicable to this structure .

[0041] Firstly, the foundation pit is excavated, and the dewatering well 5 is set at the bottom of the foundation pit. A downwater pipe 2 is arranged in the dewatering well 5, and the lower port of the downwater pipe 2 is connected with the water pump 1, and the upper port of the downwater pipe 2 is led out along the concrete bottom plate 3 to be poured, and leads to the concrete to be poured integrally connected with the concrete bottom plate 3 The wall 4 extends upward along the interior of the concrete side wall 4, and extends to a place higher than the groundwater level. When leading out, the do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com