Industrial furnace door sealing device simple in operability

An industrial furnace and operational technology, which is applied in the field of sealing devices for industrial furnace doors, can solve problems such as insufficient temperature, insufficient sealing, and failure to ensure the sealing of the furnace body, and achieve the effect of increasing work efficiency and simple and convenient sealing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

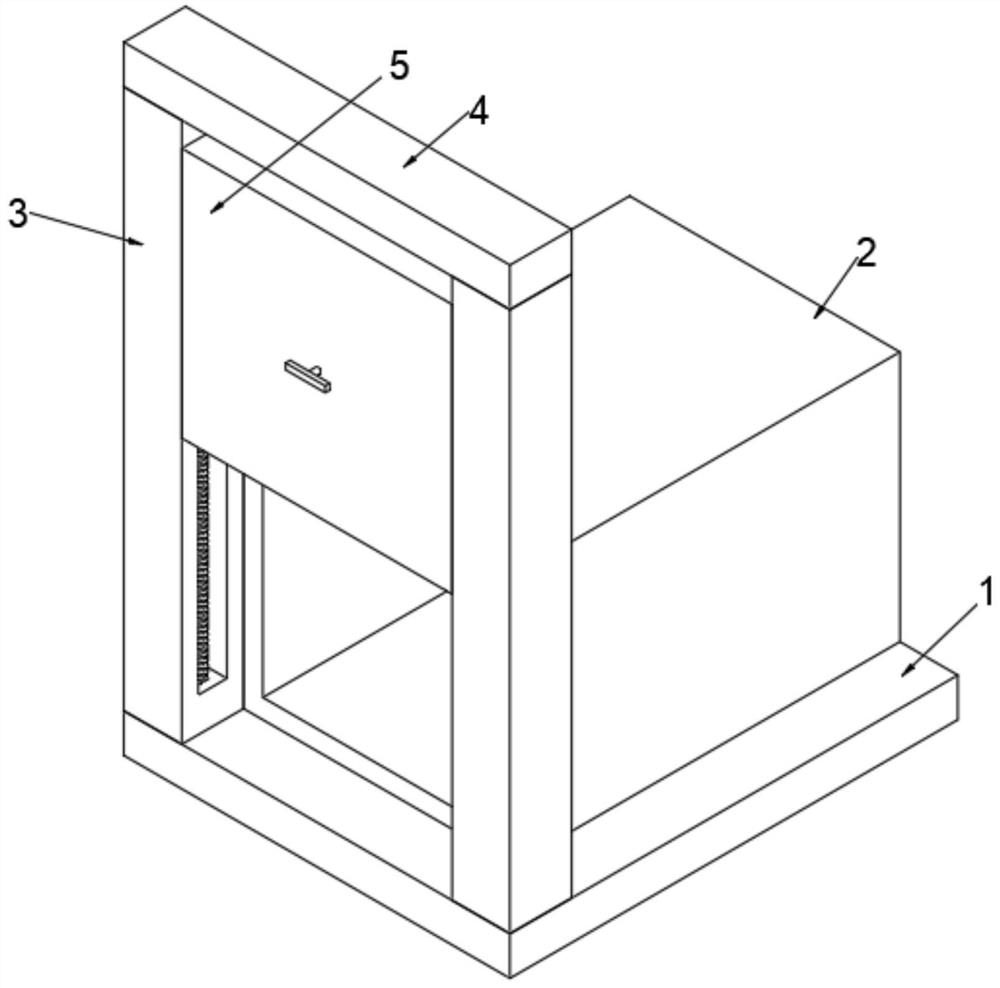

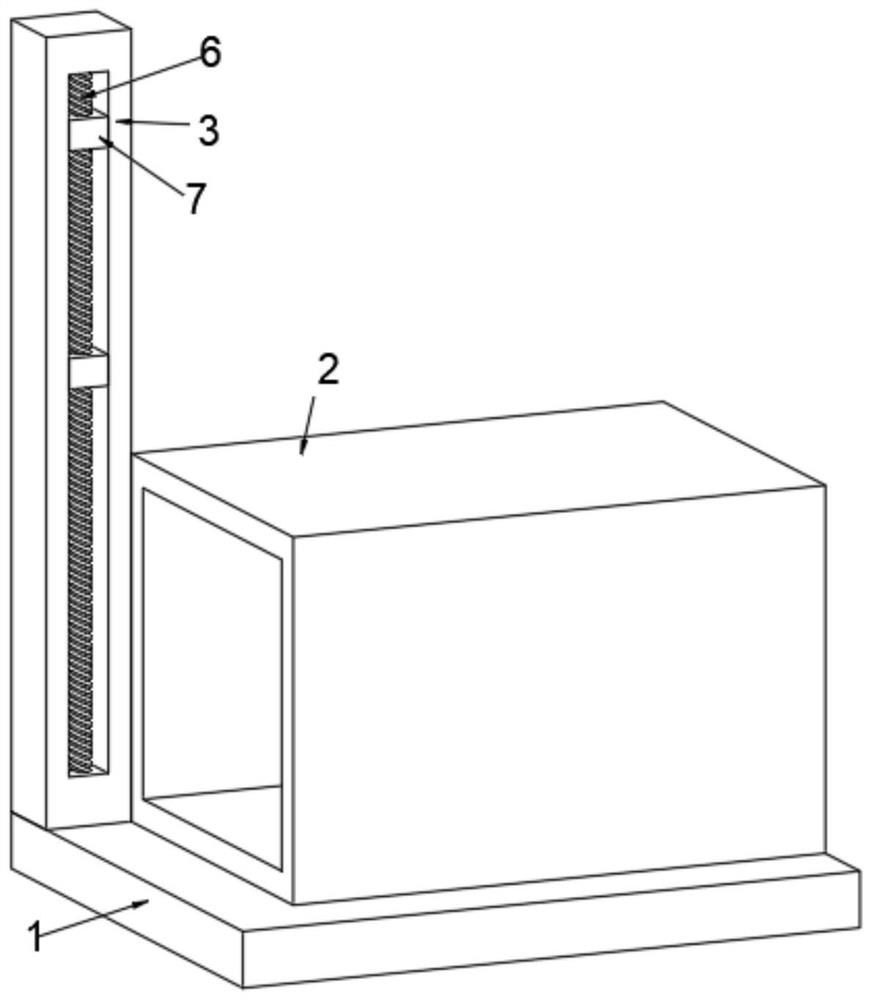

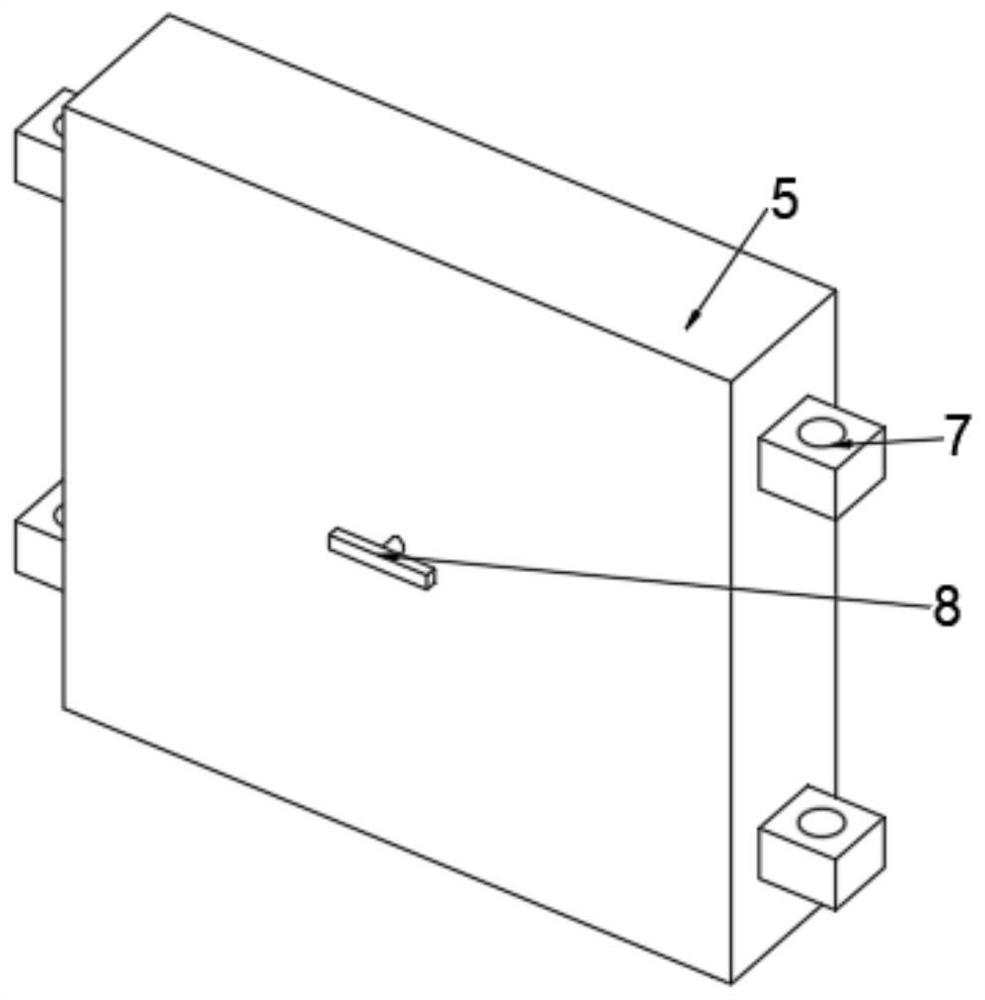

[0027] see Figure 1-Figure 6 , the present invention provides a technical solution: an industrial furnace door sealing device with simple operability, including a base 1, a furnace body 2 and a lifting column 3 are fixedly installed on the top of the base 1, and two adjacent lifting columns 3 The top of the lifting column 3 is fixedly installed with a top plate 4, and the inside of the lifting column 3 is movably installed with a first threaded rod 6, and the outer side of the first threaded rod 6 is threaded with a first moving block 7, and is fixed between two adjacent first moving blocks 7. Furnace door 5 is installed, and the back side of furnace door 5 is movably installed with heat insulation board 9, and the inside of furnace door 5 is provided with installation cavity, and the first partition plate 12, the second partition plate 13 and installation cavity are fixedly installed respectively in the installation cavity. plate 14, the mounting plate 14 is fixedly installe...

Embodiment 2

[0035] see Figure 4-Figure 5 , the present invention provides a technical solution: an industrial furnace door sealing device with simple operability, including a base 1, a furnace body 2 and a lifting column 3 are fixedly installed on the top of the base 1, and two adjacent lifting columns 3 The top of the lifting column 3 is fixedly installed with a top plate 4, and the inside of the lifting column 3 is movably installed with a first threaded rod 6, and the outer side of the first threaded rod 6 is threaded with a first moving block 7, and is fixed between two adjacent first moving blocks 7. Furnace door 5 is installed, and the back side of furnace door 5 is movably installed with heat insulation board 9, and the inside of furnace door 5 is provided with installation cavity, and the first partition plate 12, the second partition plate 13 and installation cavity are fixedly installed respectively in the installation cavity. plate 14, the mounting plate 14 is fixedly installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com