Gas nozzle for industrial kiln and distribution method using same

A gas burner and kiln technology, applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of large excess air coefficient, short service life of burner, high gas consumption, etc., and achieve long flame, long service life, good rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

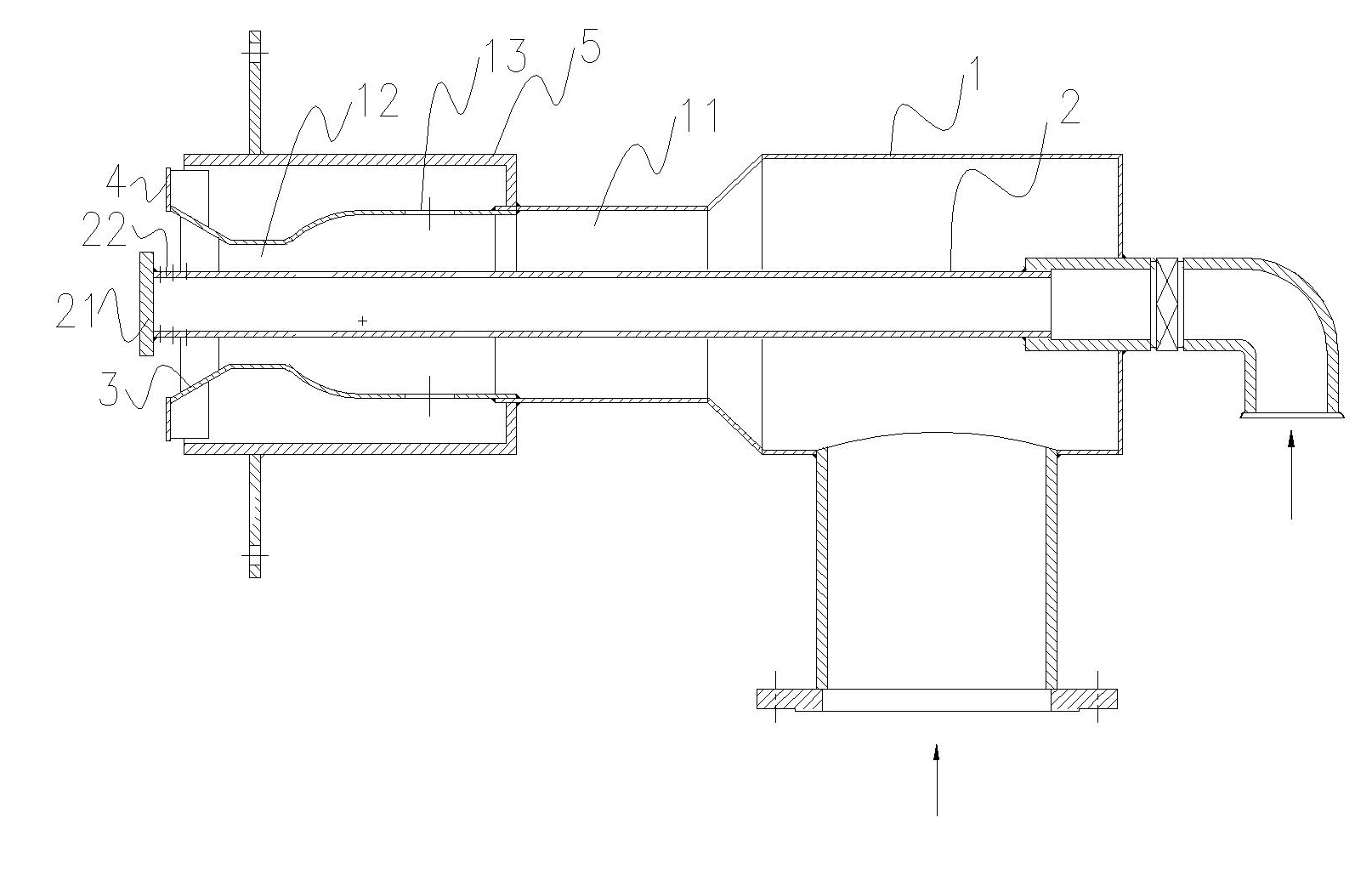

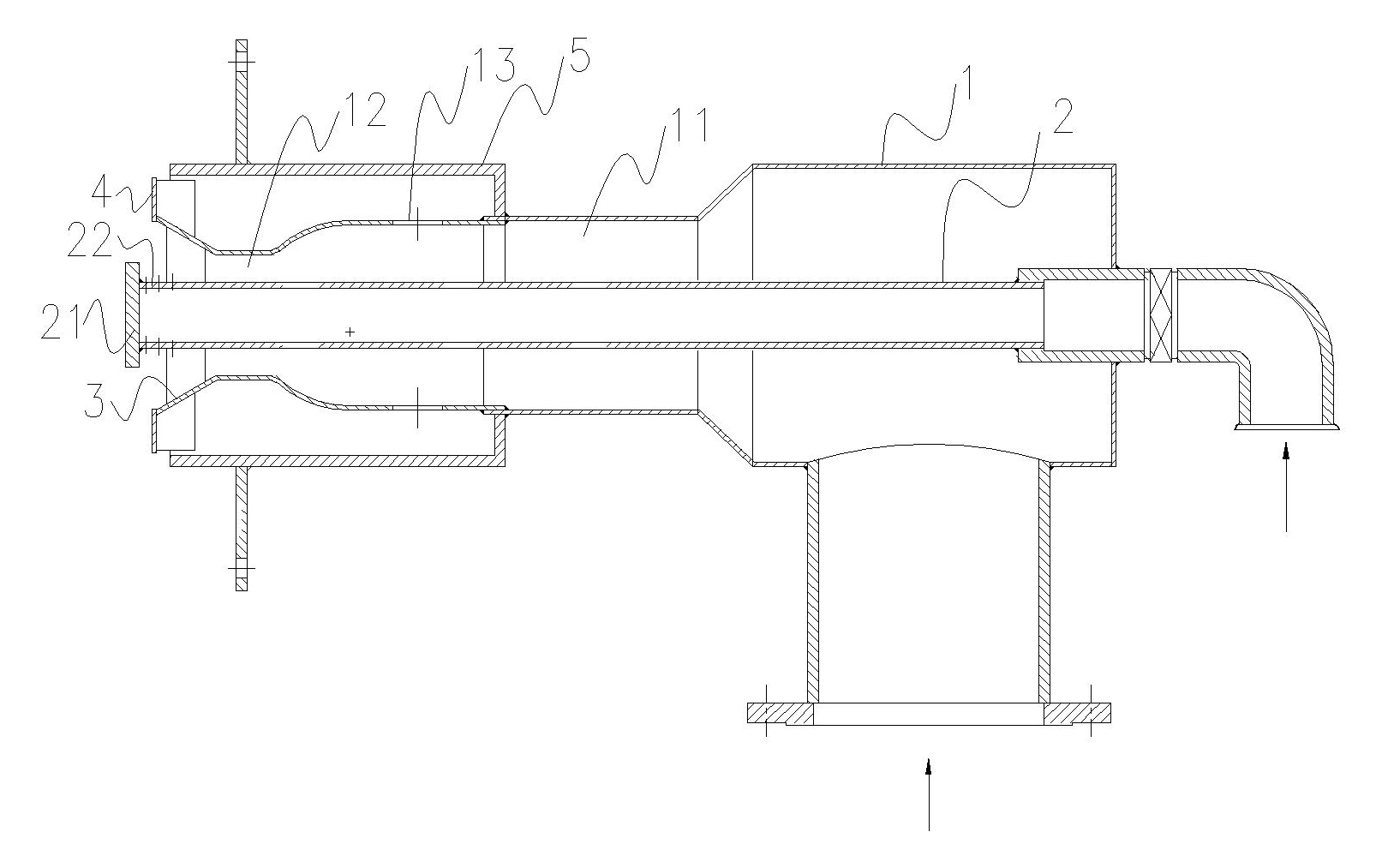

[0010] From figure 1 It can be seen that the gas burner used in the industrial kiln of the present invention comprises an outer tube 1 and an inner tube 2, the front end of the outer tube is provided with a bell mouth 3, the bell mouth has a burner lip 4, and the inner tube 2 runs through the outer tube 1, the outer tube 1 has at least two openings to form corresponding acceleration zones. In this embodiment, the outer tube 1 has two openings to form the first acceleration zone 11 and the second acceleration zone 12. The second acceleration zone The front end of 12 is that a bell mouth 3 is connected with burning lip limit 4. The front part of the inner pipe 2 is evenly distributed with gas outlets 21 (three in this embodiment) on the side wall, and a baffle 22 is provided on the end surface, so that the gas can reach the bell mouth 3 from the side gas outlets 21 and mix with air to form vortex. When the opening angle of the bell mouth 3 is 60°, it is most beneficial for the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com