Accelerated flash furnace ignition device of ore concentrate

An ignition device and flash furnace technology, applied in furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of accelerated concentrate ignition, short flame, no penetrating power, etc., to achieve accelerated collision and settlement, and long flame. , Improve the effect of flow field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

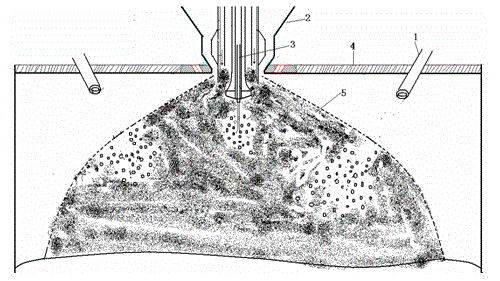

[0010] Such as figure 1 As shown, on the top of the reaction tower 4 of the copper flash smelting furnace, several cluster jet oxygen and natural gas guns 1 are symmetrically distributed around the concentrate nozzle 2, and the cluster jet oxygen and natural gas guns 1 are all installed around the concentrate nozzle at a certain inclination angle. Of course, the cluster jet oxygen and natural gas gun 1 here can also be installed vertically to the top of the flash furnace reaction tower, and the cluster jet oxygen and natural gas gun 1 can be selected from the Praxair cluster jet oxygen and natural gas gun (U.S. Patent, No. 5814125); In addition, in the center of the concentrate nozzle, a central cluster jet oxygen gas lance 3 is used to replace the original natural gas burner, and the installation position of the central cluster jet oxygen gas gun 3 is the same as that of the natural gas burner. In this way, the copper concentrate at normal temperature is ejected from the conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com