Limiting current oxygen sensor

A limiting current type, oxygen sensor technology, applied in the field of oxygen sensors, can solve problems such as composite ceramic cracking, deformed solid particles, sensor cracking, etc., and achieve strong oxygen measurement ability, good sealing, and prevent oxygen leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

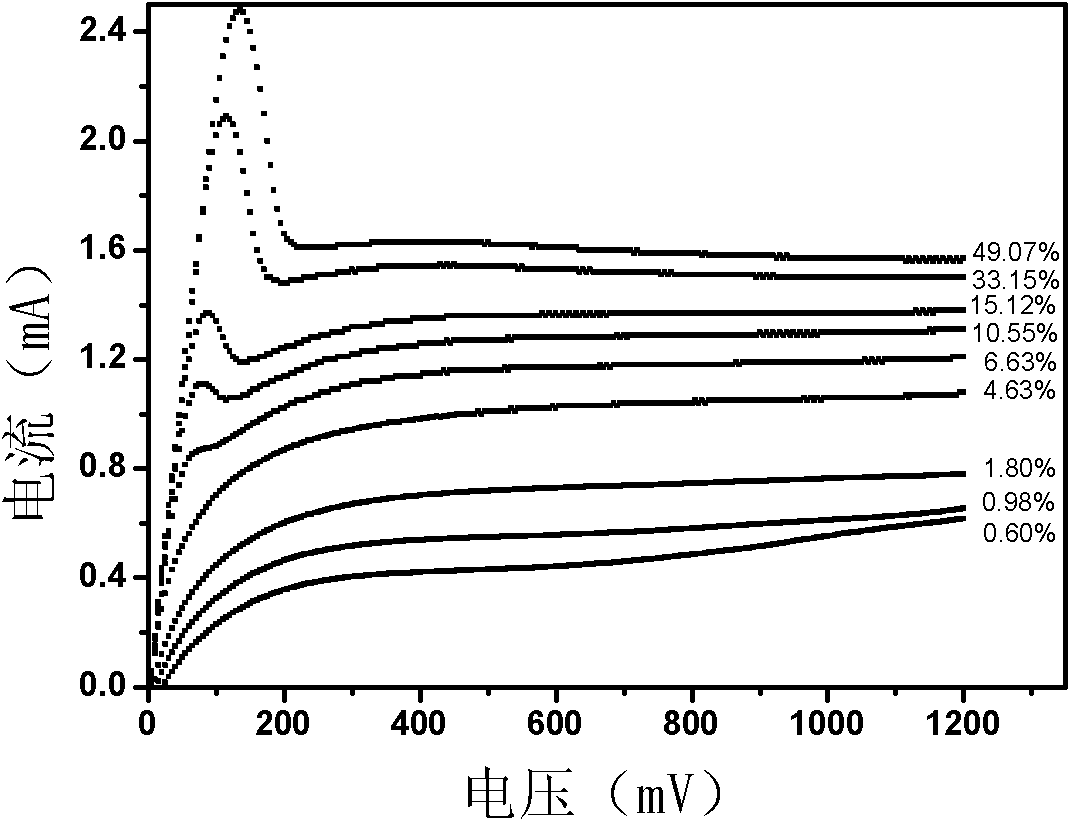

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

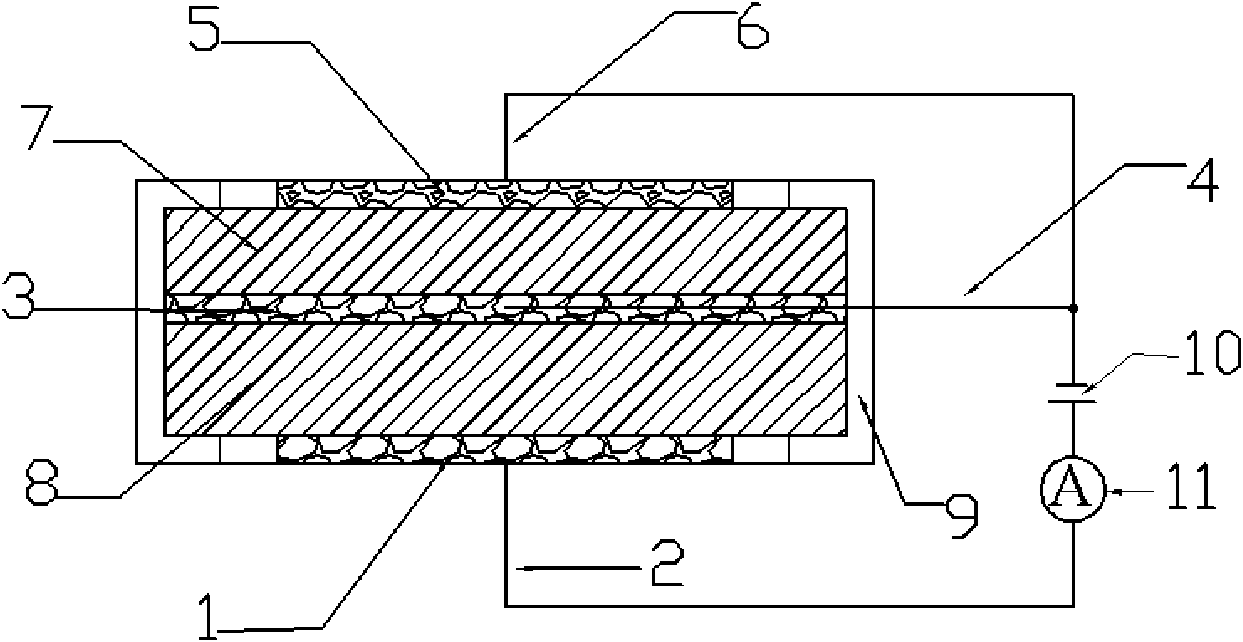

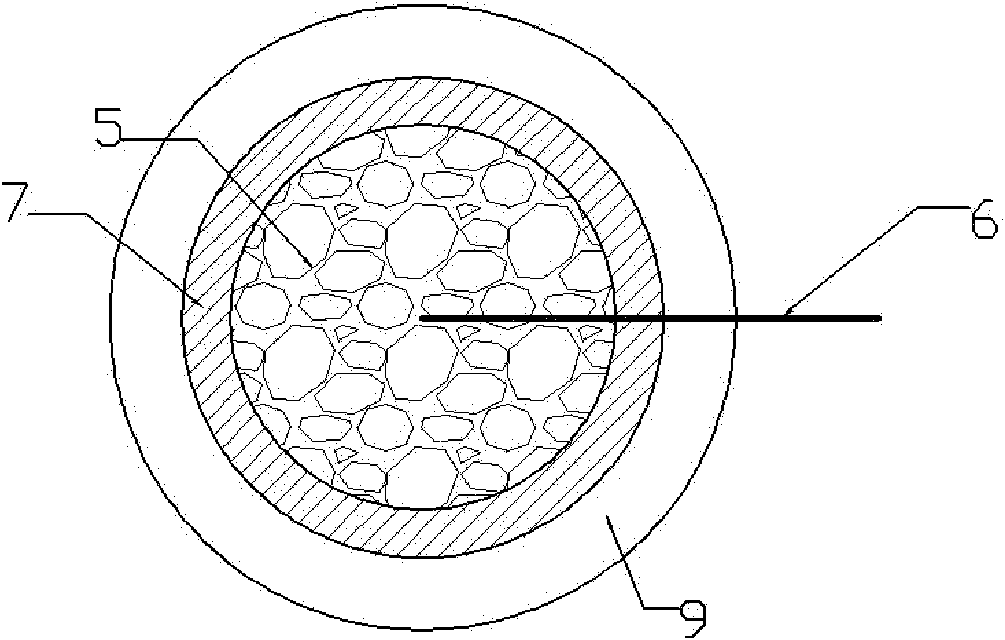

[0013] Such as figure 1 As shown in the figure, positive collector layer 1; positive collector layer lead 2; negative collector layer 3; negative collector layer lead 4; equipotential electrode layer 5; equipotential electrode layer lead 6; dense diffusion barrier layer 7; electrolyte layer 8; encapsulation layer 9; power supply 10; ammeter 11. The present invention is a limiting current type oxygen sensor using 8%mol yttrium stabilized zirconia (8YSZ) as the material of the dense diffusion barrier layer 7 and the solid electrolyte layer 8. It consists of an equipotential electrode layer 5, a dense diffusion barrier layer 7, a negative collector The electrode layer 3, the electrolyte layer 8, the positive collector layer 1 and the encapsulation layer 9 are composed, the positive collector layer 1 is arranged on the lower surface of the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com