Dry etching method

A dry etching and etching technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as damage to the device structure and unsatisfactory cleaning effect, and achieve the reduction of particle residues, particle residues, and damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

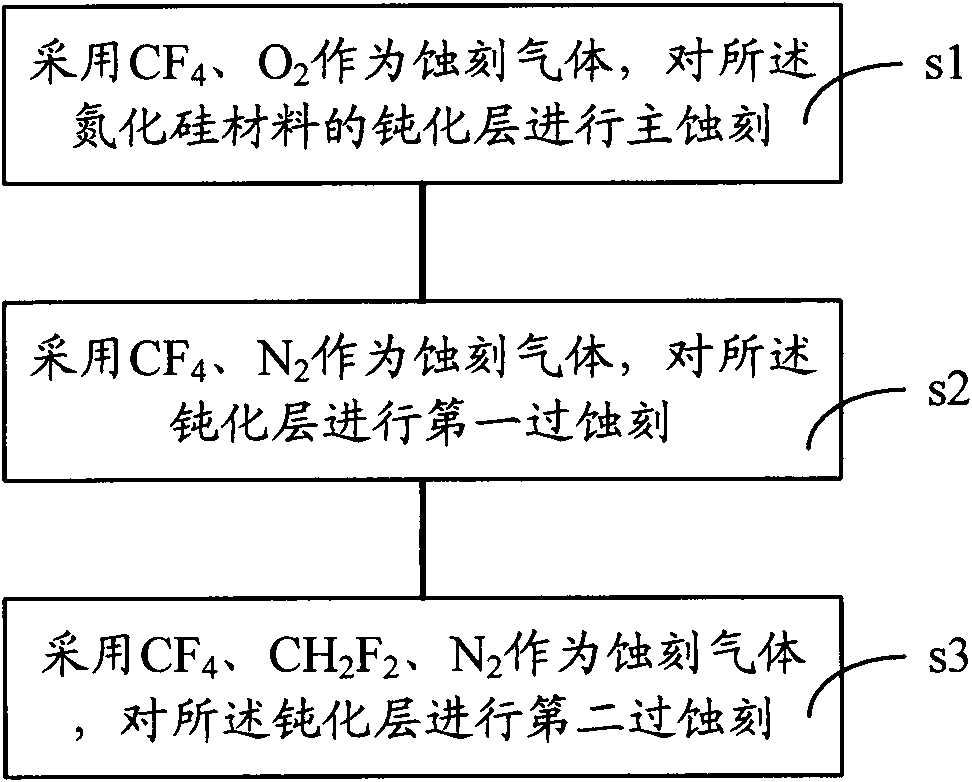

[0016] Based on this, the dry etching method of the present invention achieves the purpose of reducing particle residues by improving the etching process and reducing the damage of the etching gas of the dry etching to the exposed non-etching materials under the premise of meeting the etching requirements. According to an embodiment of the method of dry etching of the present invention, it comprises:

[0017] The main etching and overetching are performed sequentially on the material layer to be etched, wherein the etching gas used in the overetching includes at least a gas that can increase the amount of polymer produced in the etching reaction.

[0018] In the above embodiment, by using a gas that can increase the amount of polymer generated in the etching reaction in the overetching, more polymers are generated in the etching reaction, so that the polymer forms a protective layer on the surface of the non-etching material exposed by etching , reducing the damage of the etch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com