Aqueous dispersion containing polysaccharide particulate gel and method for producing the same

A polysaccharide and dispersion technology, which can be used in medical preparations with non-active ingredients, preparations for skin care, and liquid delivery, etc., can solve problems such as inability to apply, achieve good drug efficacy sustainability, and inhibit the loss of effective ingredients. , the effect of high in vivo safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0078] The method for preparing a polysaccharide particulate gel-containing aqueous dispersion of the present invention is characterized by comprising the steps of: heating the polysaccharide in an aqueous medium to a gel transition temperature or higher, and dissolving the polysaccharide in the above-mentioned A dissolving step in an aqueous medium; a step of cooling the polysaccharide dissolved in the aqueous medium to below the gel transition temperature while applying an external force, and making the polysaccharide into a particulate gel; cooling the polysaccharide in the aqueous medium The step of irradiating the above-mentioned particulate gel with ionizing radiation to obtain an aqueous dispersion containing polysaccharide particulate gel.

[0079] "The dissolving step of heating the polysaccharide in an aqueous medium to a temperature above the gel transition temperature to dissolve the polysaccharide in the aqueous medium" can be carried out according to methods descr...

Embodiment 1

[0120] (Preparation of aqueous dispersion containing agar microgel)

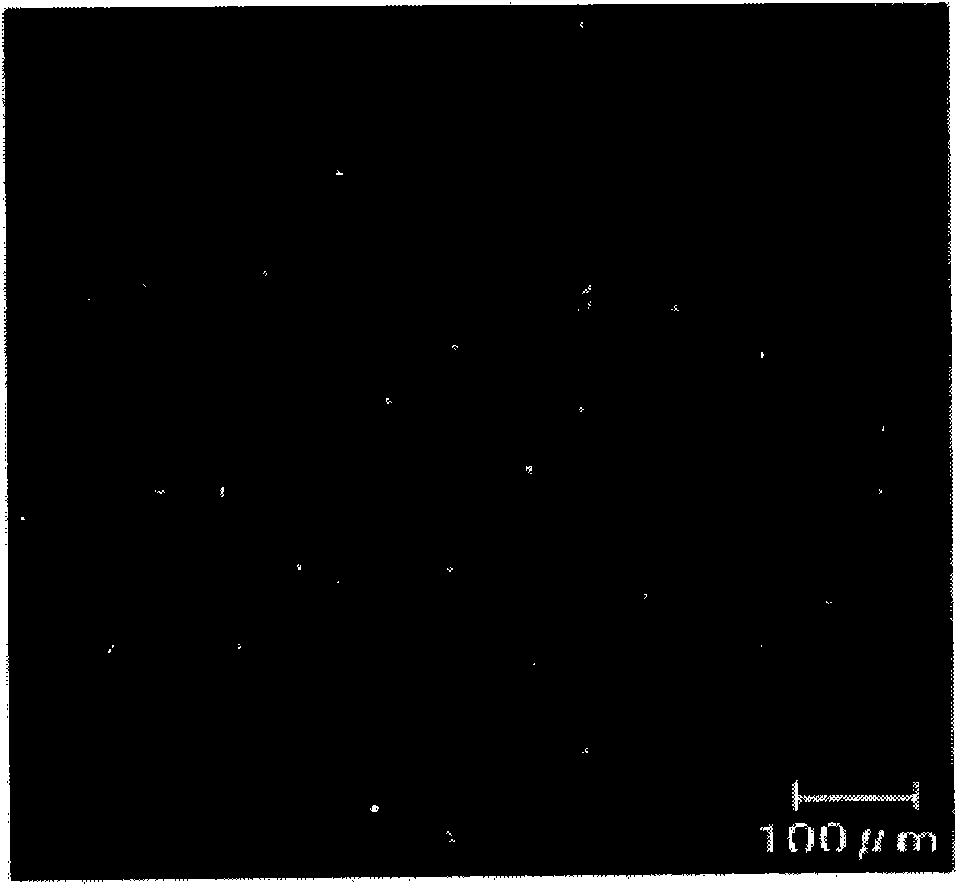

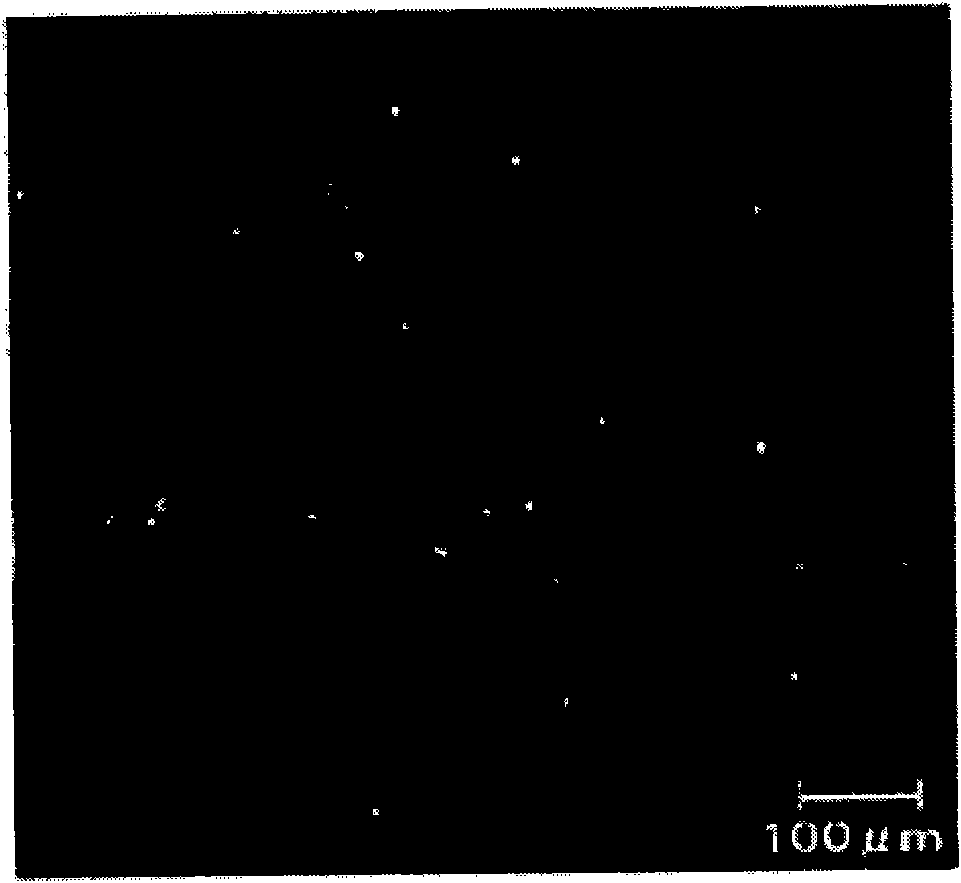

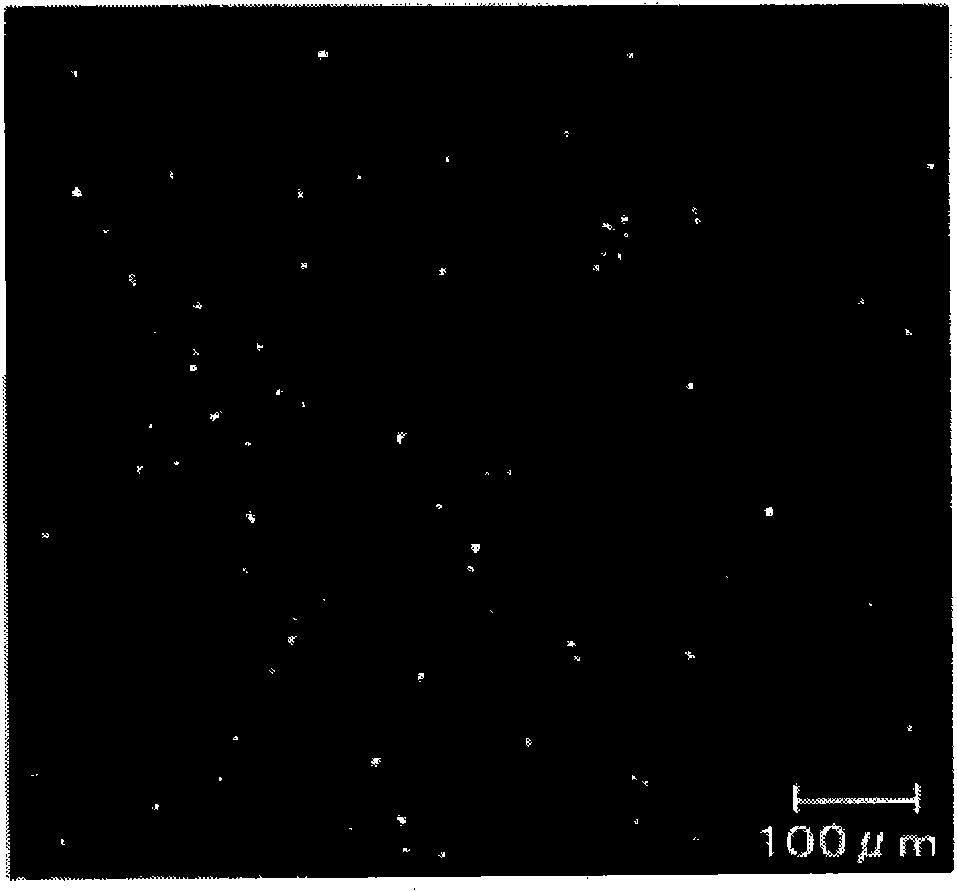

[0121] Weigh 0.5% (weight) of agar (AX-30, manufactured by Ina Food Industry) in a closed container, add 99.5% (weight) of distilled water (distilled water for injection, prepared by Dazhuo Pharmaceutical Co., Ltd.) to disperse the agar. Then, the airtight container was immersed in an oil bath set at 100° C., and stirred at 700 rpm for 30 minutes using a mechanical stirrer (BL-600, manufactured by HEIDON) to dissolve the agar. Then the airtight container was lifted from the oil bath, and left to cool at room temperature for 210 minutes while stirring at 700 rpm using a mechanical stirrer to prepare an aqueous dispersion containing agar microgel (hereinafter referred to as aqueous dispersion A).

[0122] (Irradiation of aqueous dispersions containing agar microgels)

[0123] 10 ml of aqueous dispersion A containing particulate agar was collected, put into an airtight container, and gamma rays were irradiated...

Embodiment 2

[0127] 10 ml of aqueous dispersion A containing particulate agar was collected, put into a closed container, and the liquid depth was 5 mm, and irradiated with electron beams at an irradiation voltage of 5 MeV and a dose of 25 kGy to obtain aqueous dispersion C. Then, the same heat resistance evaluation test as in Example 1 was performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com