Storage tank for a cryogenic medium

A low-temperature medium, storage box technology, applied in gas treatment/storage effect, gas treatment/storage purpose, gas/liquid distribution and storage, etc., can solve problems such as bubble formation, pressure difference balance state interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

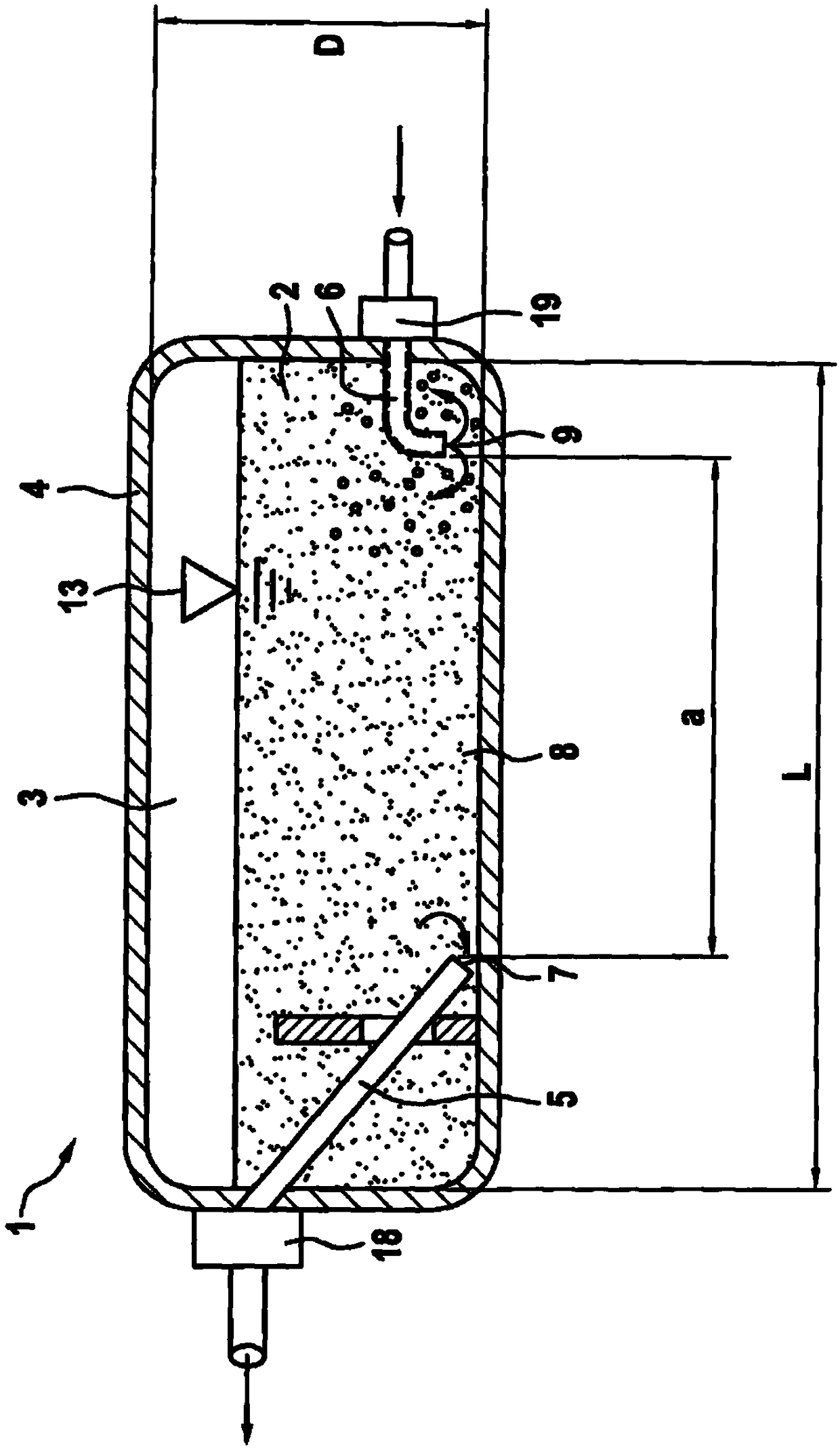

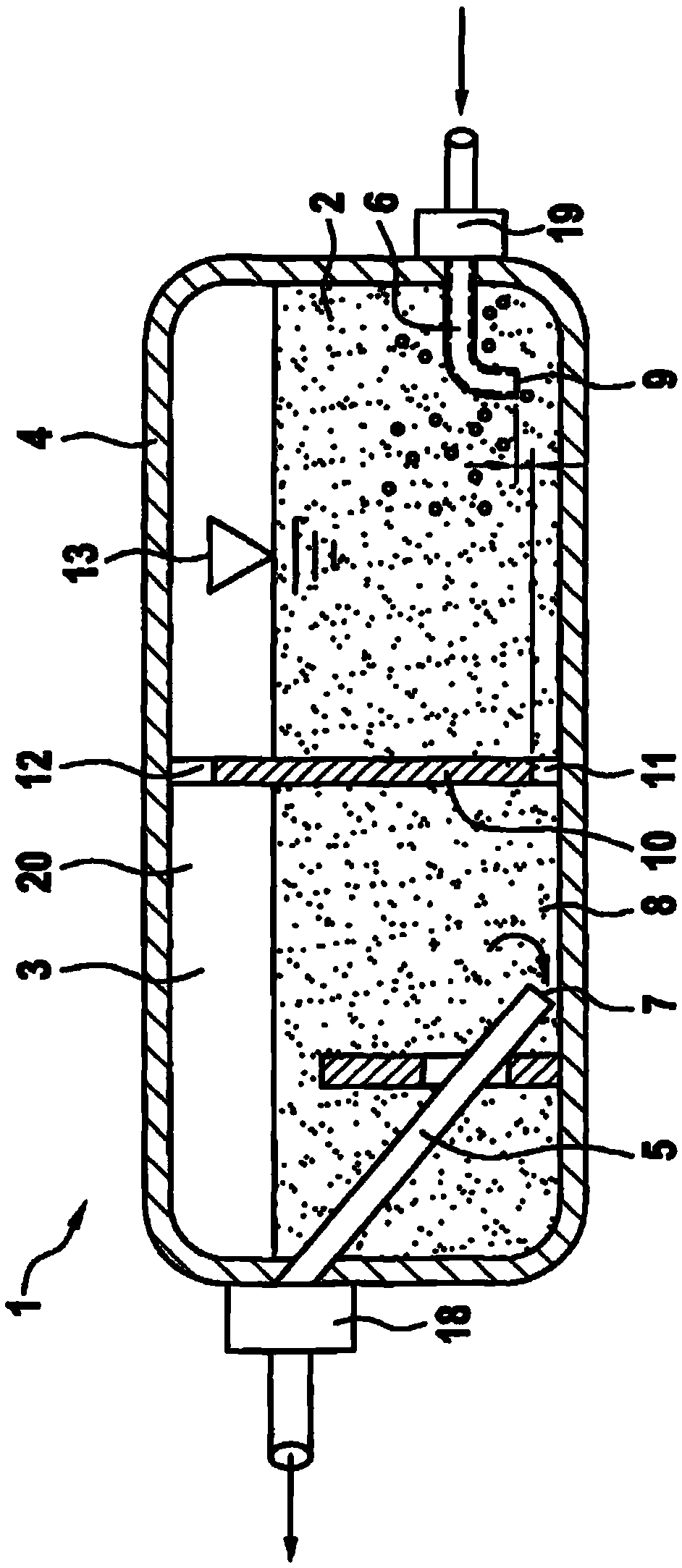

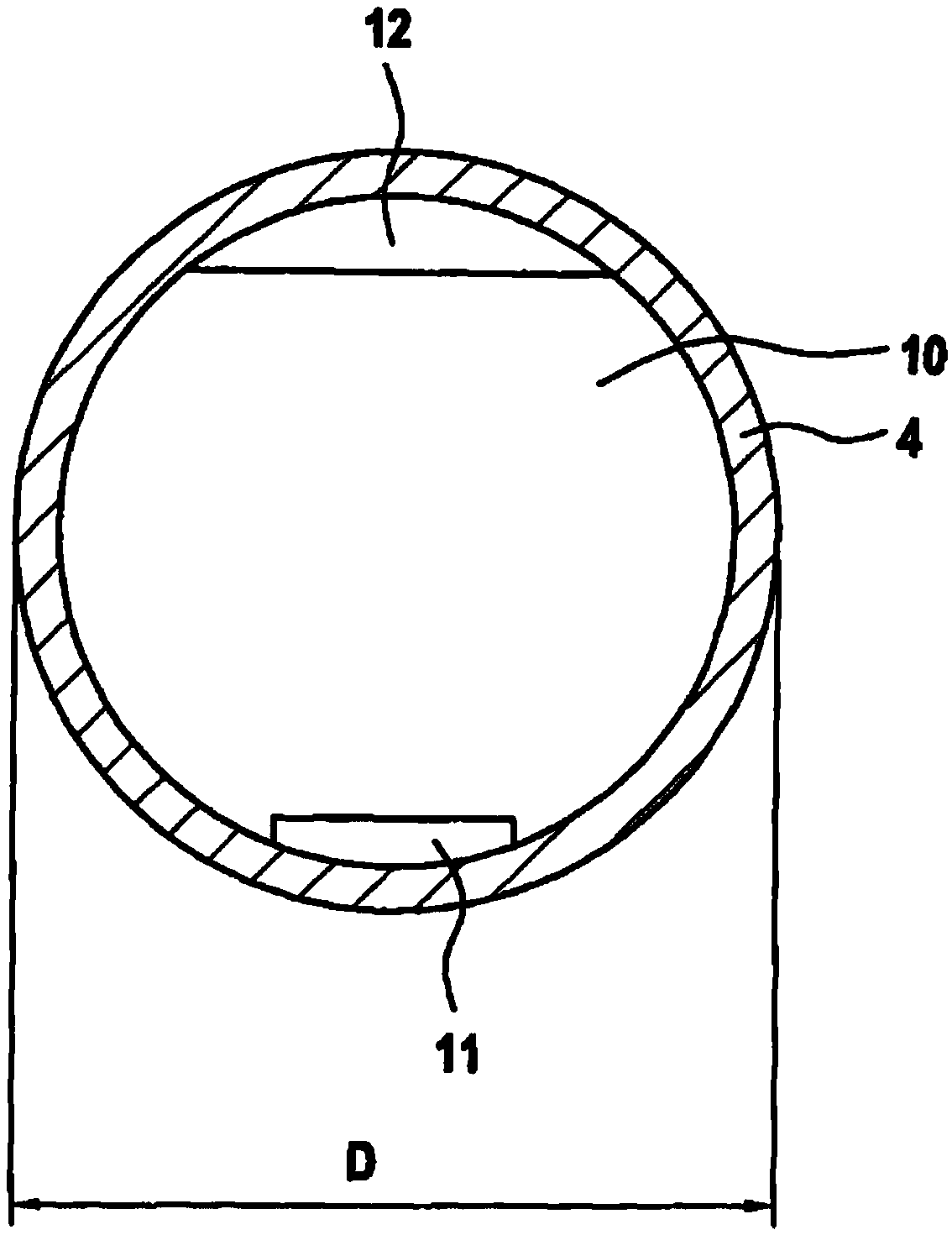

[0031] exist figure 1 The storage tank 1 shown in is used to store cryogenic medium 2 . In this case, in particular liquefied natural gas (LNG) may be involved. The medium 2 is accommodated in a tank interior 3 , which is delimited by a tank wall 4 . The tank interior 3 or the storage tank 1 has the shape of an elongated cylinder, which is defined by a length L and a diameter D. As shown in FIG. Storage box 1 is rounded on opposite end sides. Furthermore, on each end side a line 5 , 6 leads through the tank wall 4 into the tank interior 3 .

[0032] The first line 5 forms an extraction point 7 in the bottom region 8 of the tank interior 3 . The liquid medium 2 stored in the storage tank 1 is sucked in by means of a pump 18 connected to the line 5 and arranged on the outside of the storage tank 1 . The second line 6 serves to conduct the gaseous leakage quantity back into the storage tank 1 , wherein the second line 6 defines an insufflation point 9 . Since the blow-in po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com