Coaxial double-speed threshing cylinder

A threshing drum and two-speed technology, which is applied in the field of semi-feeding combine harvesters, can solve the problems of low connection strength of the anti-clogging structure and high use and maintenance costs, so as to improve the overall strength and work reliability, reduce use and maintenance costs, Create simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

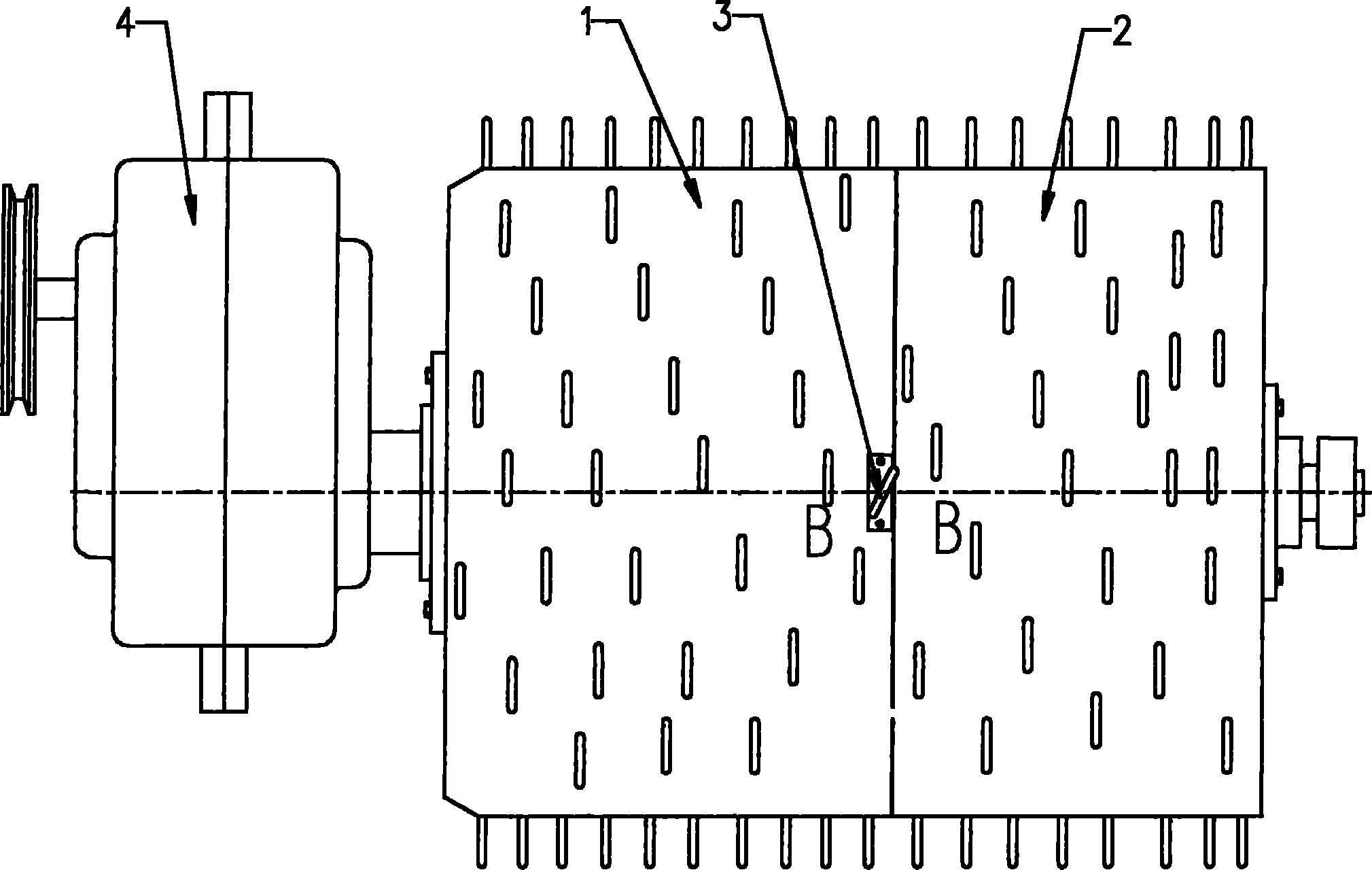

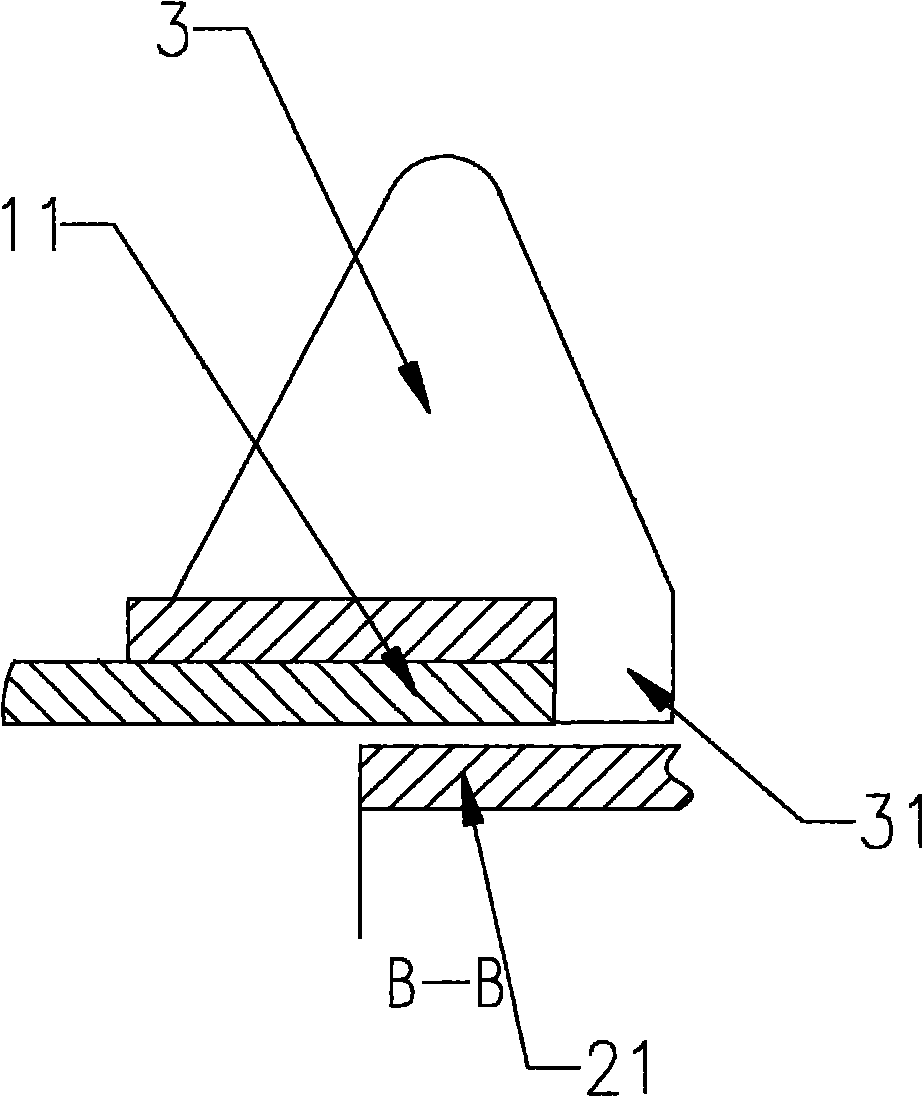

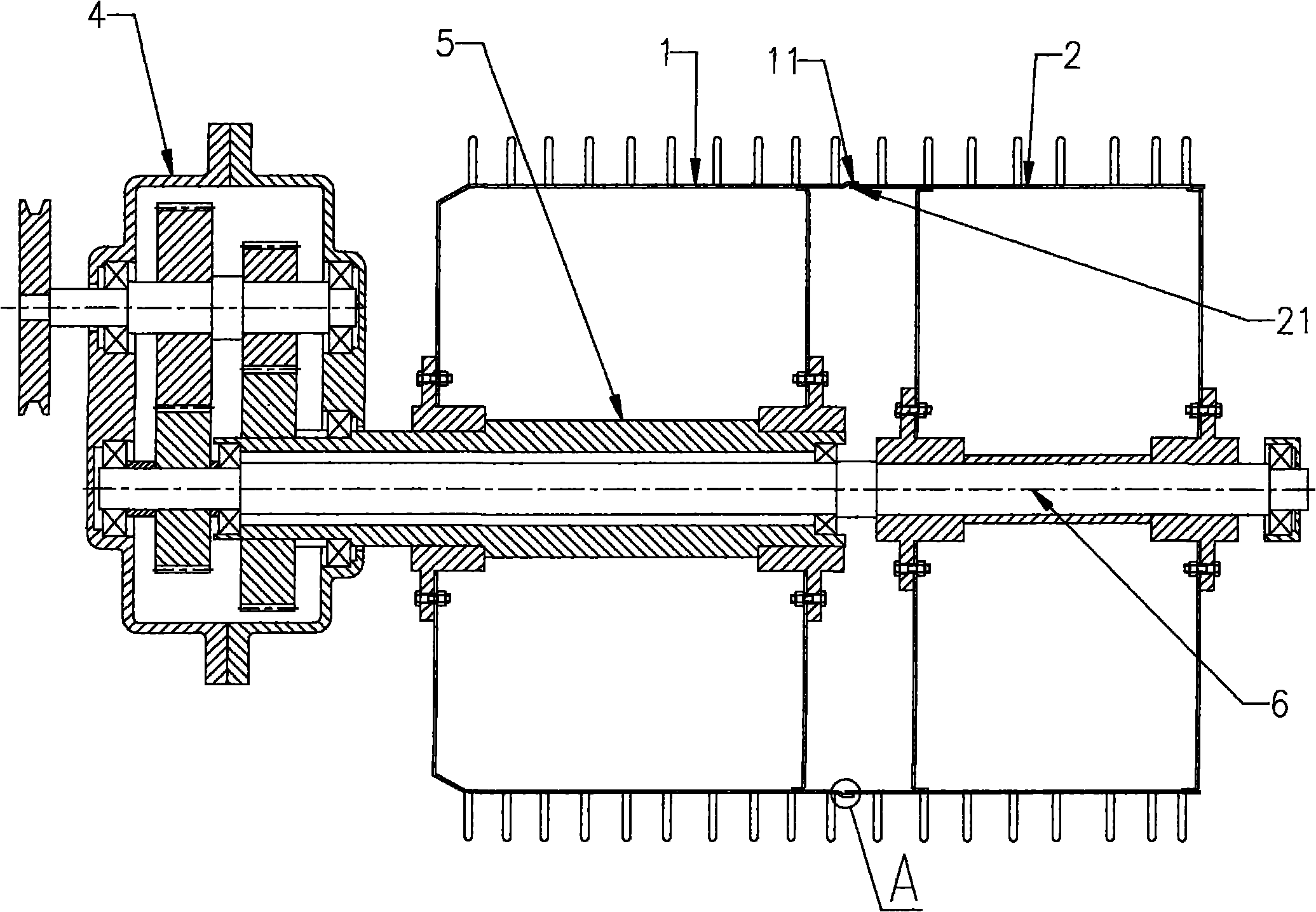

[0018] Such as figure 1 , image 3 As shown, the present invention is a coaxial double-speed threshing drum, which includes a high-speed drum 2 and a low-speed drum 1 with equal lengths. The drive shaft 11 of the barrel is a sleeve shaft, and its driving end is its left end. The drive shaft 21 of the high-speed barrel passes through the drive shaft of the low-speed barrel, and the driving end of the drive shaft 21 of the high-speed barrel is its left end. And the speed ratio of the high-speed cylinder 2 is a fixed value. Such as image 3 As shown, the high-speed barrel 1 is socketed with the right-end connecting portion 11 of the low-speed barrel through the left-end connecting portion 21, wherein the left-end connecting portion 21 of the high-speed barrel extends into the right-end connecting portion 11 of the low-speed barrel by 20mm, and the low-speed barrel The outer diameter of the body is 5mm larger than that of the high-speed barrel, such as figure 2 As shown, the ...

Embodiment 2

[0021] On the basis of embodiment 1, the characteristics of this embodiment are, as Figure 5 As shown, the outer diameter of the body of the low-speed barrel 1 is equal to the outer diameter of the barrel of the high-speed barrel 2, and the right end connecting portion 11 of the low-speed barrel is a reaming structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com