Descaling tool, descaling device and descaling method for pipe

A tool and pipeline technology, applied in the field of pipeline dredging, can solve problems such as shortening the service life of pipelines, hydrogen leakage, pipeline damage, etc., and achieve the effect of high descaling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059]Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

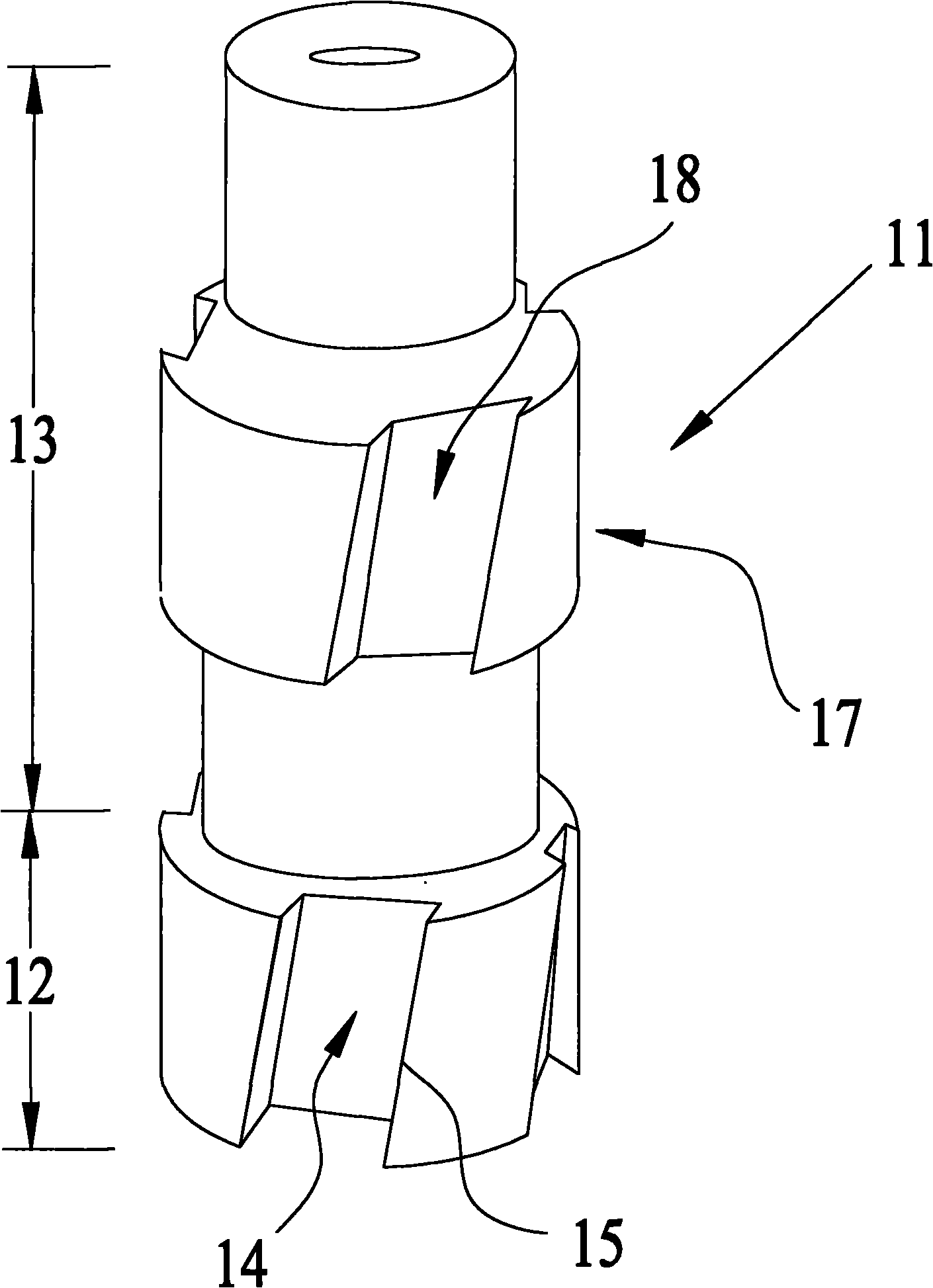

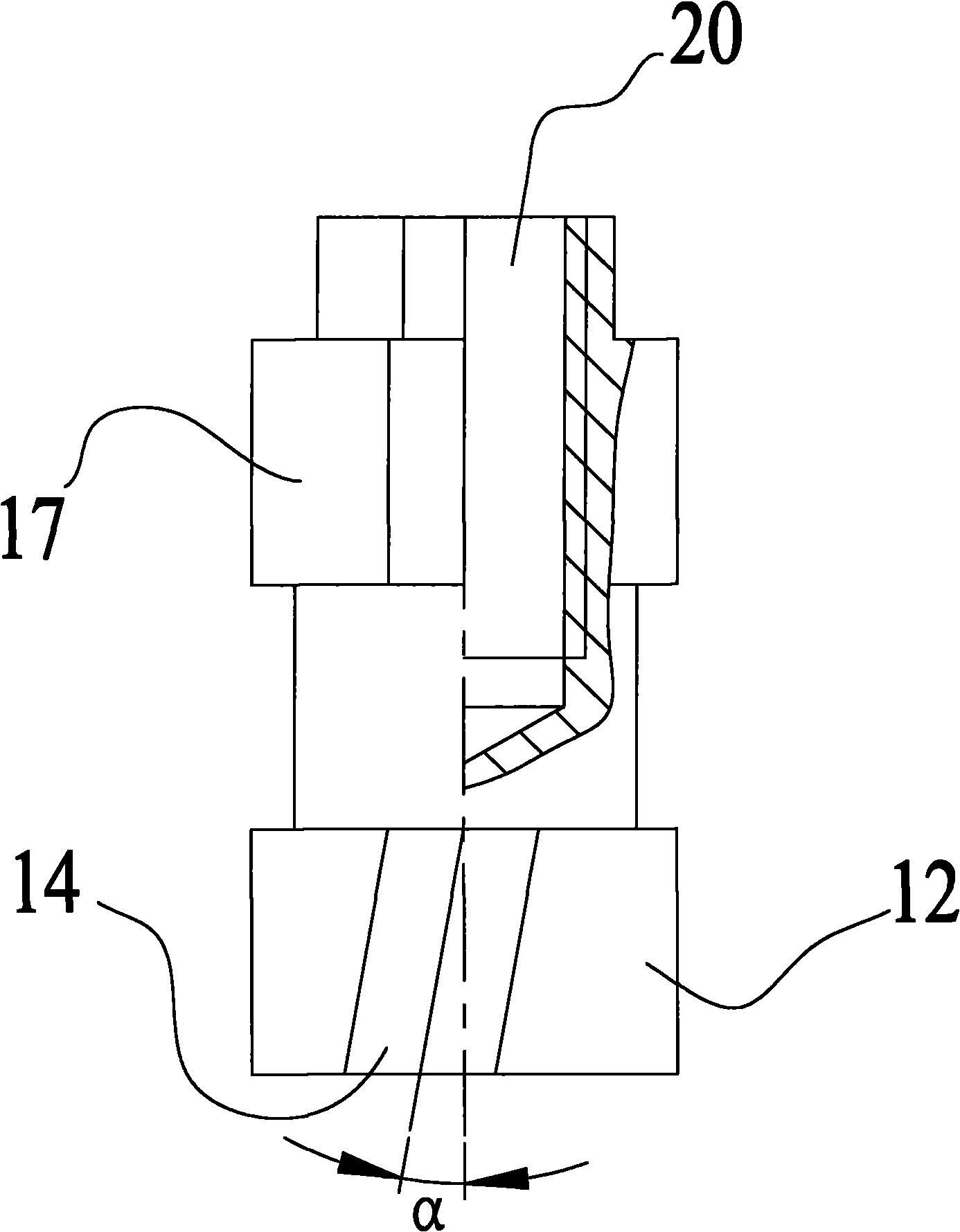

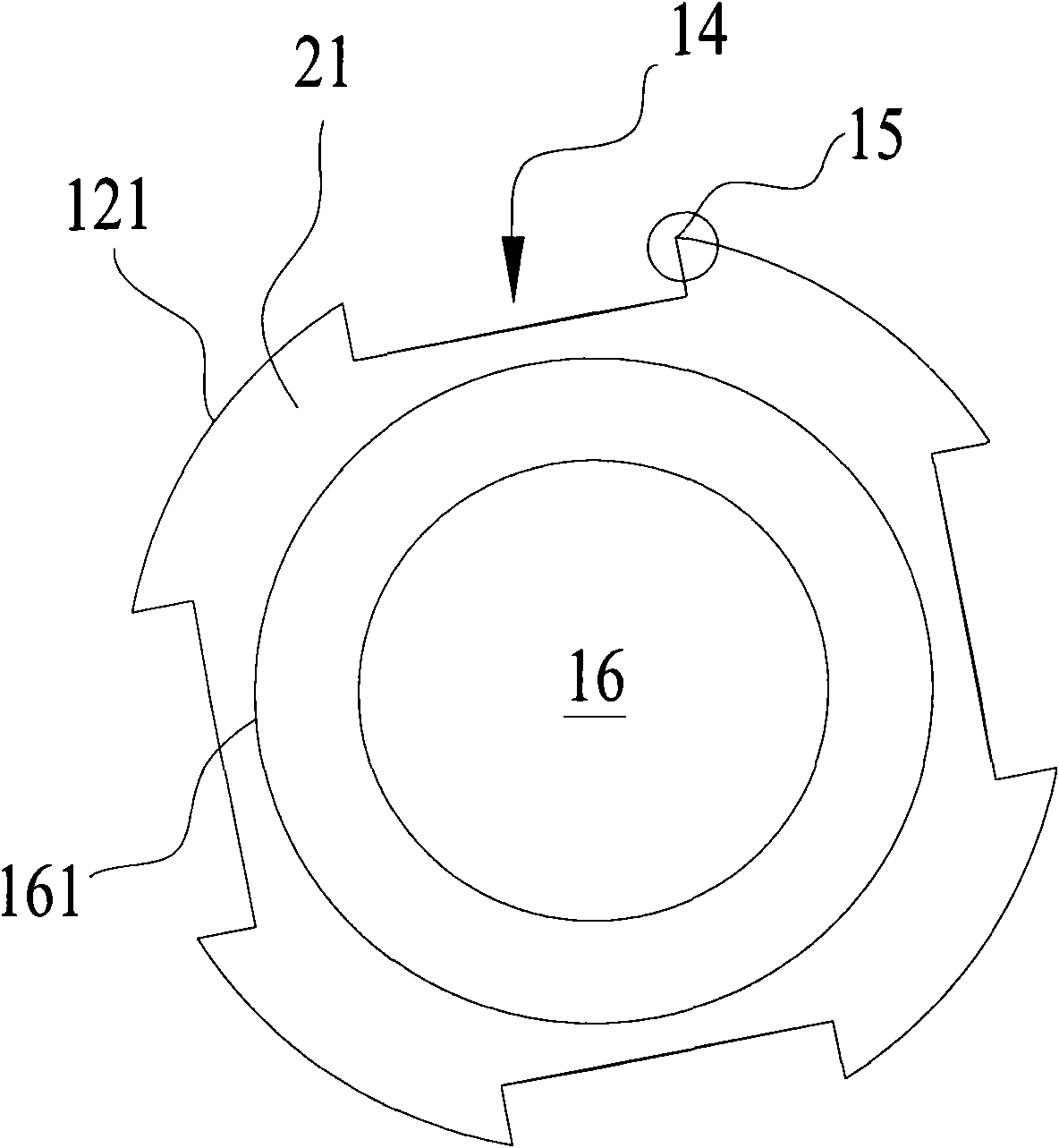

[0060] like figure 1 As shown, the descaling tool for pipelines provided by the present invention includes a tool body 11, which includes a cylindrical cutting portion 12 and a connecting portion 13 axially extending from the cutting portion 12, the cutting portion 12 There are a plurality of helical grooves 14 uniformly distributed on the outer peripheral surface of the cutting portion 12 around the central axis of the cutting portion 12 .

[0061] The descaling tool provided by the present invention is used for the descaling treatment of pipelines. Specifically, when using the descaling tool for descaling treatment, the descaling tool is placed in the pipeline...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Helix angle α | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com