Spindle axis cooling device of numerical control machine

A technology of cooling device and CNC machine tool, which is applied in metal processing mechanical parts, maintenance and safety accessories, metal processing equipment, etc., can solve the problems of inability to cool the inner ring of the main shaft, and achieve the effect of convenient cooling and improved anti-torsion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

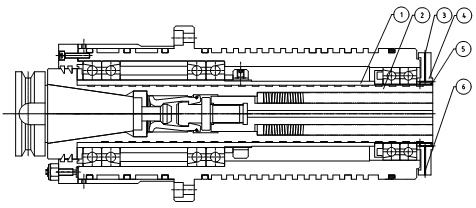

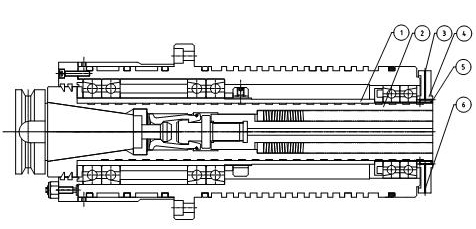

[0012] Such as figure 1 As shown, the present invention is provided with the inner layer sleeve 2 of the spindle shaft center. The outer surface of the inner layer sleeve 2 of the spindle shaft center is processed with spiral grooves, which can store and circulate the cutting fluid. The inner layer sleeve 2 of the spindle shaft center is covered with a spindle Shaft outer sleeve 1, the outer sleeve 1 of the spindle shaft and the inner sleeve 2 of the main shaft adopt an interference fit. After the two parts are turned, the outer sleeve 1 of the spindle shaft is heated and connected Set 2 is assembled into an integral part, and then the overall heat treatment and precision grinding and assembly are carried out. Then the tail end of the main shaft shaft center outer layer sleeve 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com