Assembly tool for front shock absorbers of motorcycle

A technology for front shock absorber and assembling tooling, which is applied in the field of tooling fixtures, can solve the problems of laborious operation, high labor intensity, damage to the front shock absorber, etc., and achieves the effect of ensuring aesthetic appearance, improving safety, and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

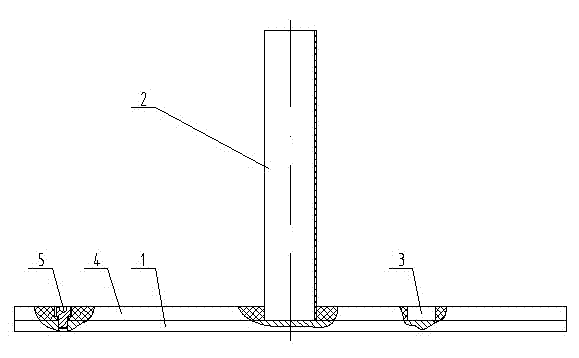

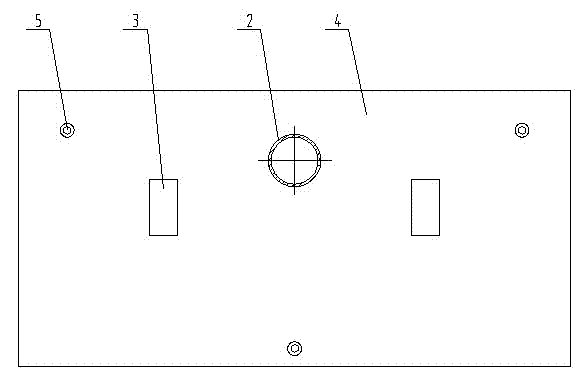

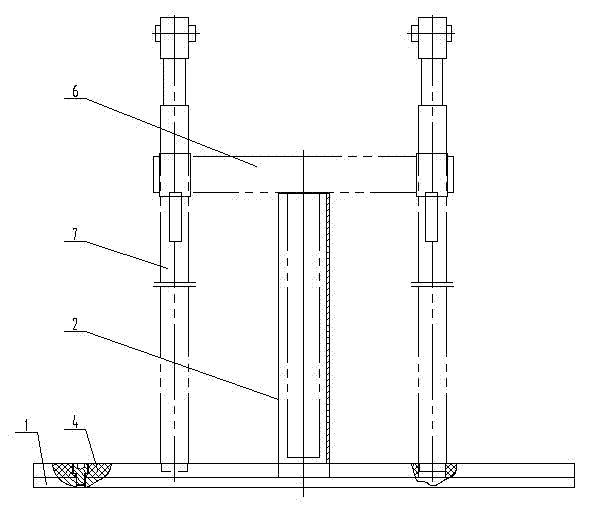

[0014] Such as figure 1 , figure 2 As shown, the present embodiment is made up of base plate 1, standpipe 2, plastic plate 4 and screw 5, and wherein base plate 1 is the rectangular plate structure of metal material, is laid on the upper plate surface of base plate 1 and is adapted to its shape and size. Plastic plate 4, the two ends of the rear part of the plastic plate 4 and the center of the front part are respectively fixed with the base plate 1 by a screw 5, and the three screws 5 are distributed in an isosceles triangle. Described standpipe 2 is positioned at the center of bottom plate 1 rear portion, and this standpipe 2 is perpendicular to the top surface of bottom plate 1, and the bottom end of standpipe 2 passes plastic plate 4, and is welded with the top surface of bottom plate 1. Positioning holes 3 are symmetrically arranged on the left and right sides in front of the standpipe 2 , the positioning holes 3 are rectangular, and the positioning holes 3 are opened o...

Embodiment 2

[0017] refer to figure 1 , figure 2 , this embodiment is made up of bottom plate 1 and standpipe 2, and standpipe 2 is vertically welded on the upper plate surface of bottom plate 1, and the left and right sides in front of standpipe 2 are symmetrically provided with positioning hole 3, and this positioning hole 3 is opened in bottom plate 1 superior.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com