Design method of wind-proof anti-theft weight restraint bracket

A design method and anti-theft technology, applied in the field of machinery, can solve the problems of high frictional resistance, sticking of falling weights, hidden dangers of driving safety, etc., and achieve the effect of good fixing effect, reduced frictional resistance and ensuring driving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

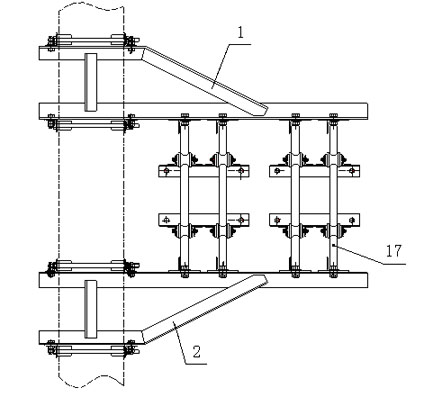

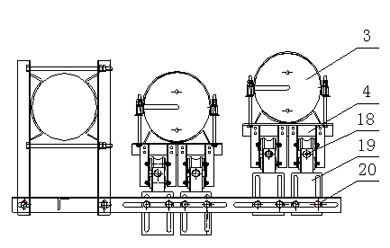

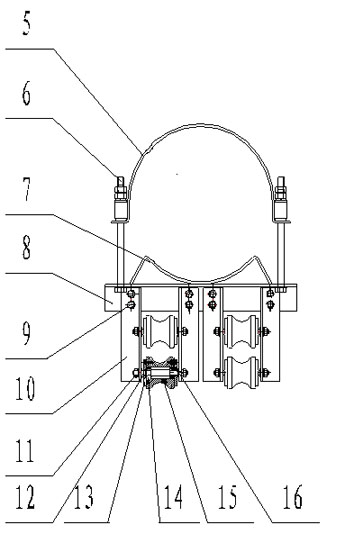

[0017] like figure 1 , image 3 As shown, the upper and lower ends of the drop mass string 3 are fixed on the upper and lower two drop mass fixing frames 4, and one end of the falling mass fixing frame 4 is the dropping mass fixing frame hoop 5, and the other end is the dropping mass fixing frame body 8 , the "M" type hoop 7 is welded on the body 8 of the drop mass fixing frame, and the two ends of the dropping mass fixing frame hoop 5 are fixed on both ends of the body 8 of the dropping mass fixing frame through M16 connecting bolts 6; One end is fixed between the "M"-shaped hoop 7 and the drop mass fixing frame hoop 5 .

[0018] like figure 2 As shown, two groups of parallel guide wheel connection angles 10 are vertically fixed on the body 8 of the drop weight fixing frame through M12 connecting bolts 9, and two parallel guide wheel connection angles 10 in each group are vertically connected with two parallel Guide pulley 15, a gap of 5 mm is formed between the two guide...

Embodiment 2

[0023] This embodiment is basically the same as Embodiment 1. The difference is that this embodiment uses one weight string 3. Therefore, the windproof and anti-theft type weight restraining frame of this embodiment includes a restraining frame bracket 1 and a set of weights. The mass fixing frame 4, a set of restricting conduits 17, a set of conduit regulating plates 19 and connecting pieces.

[0024] The described set of drop-weight fixing frames 4 includes two upper and lower drop-weight fixing frames 4, the two sets of restricting conduits 17 include two restricting conduits 17, and the described set of conduit adjusting plates 19 includes four conduit adjusting plates. 19.

[0025] The sizes of the bolts and nuts in the above embodiment are not limited to the sizes in the embodiments, they can also be adjusted according to the actual size of the weight string 3; the gap formed between the two guide pulleys 15 is not only It is limited to 5mm in the embodiment, and can al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com