Composite board and wall panel using same

A composite board and wall panel technology, applied in building components, thermal insulation, construction, etc., can solve the problems of complex installation process and poor joint strength, and achieve the effects of avoiding damage, preventing spread damage, and strengthening joint strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

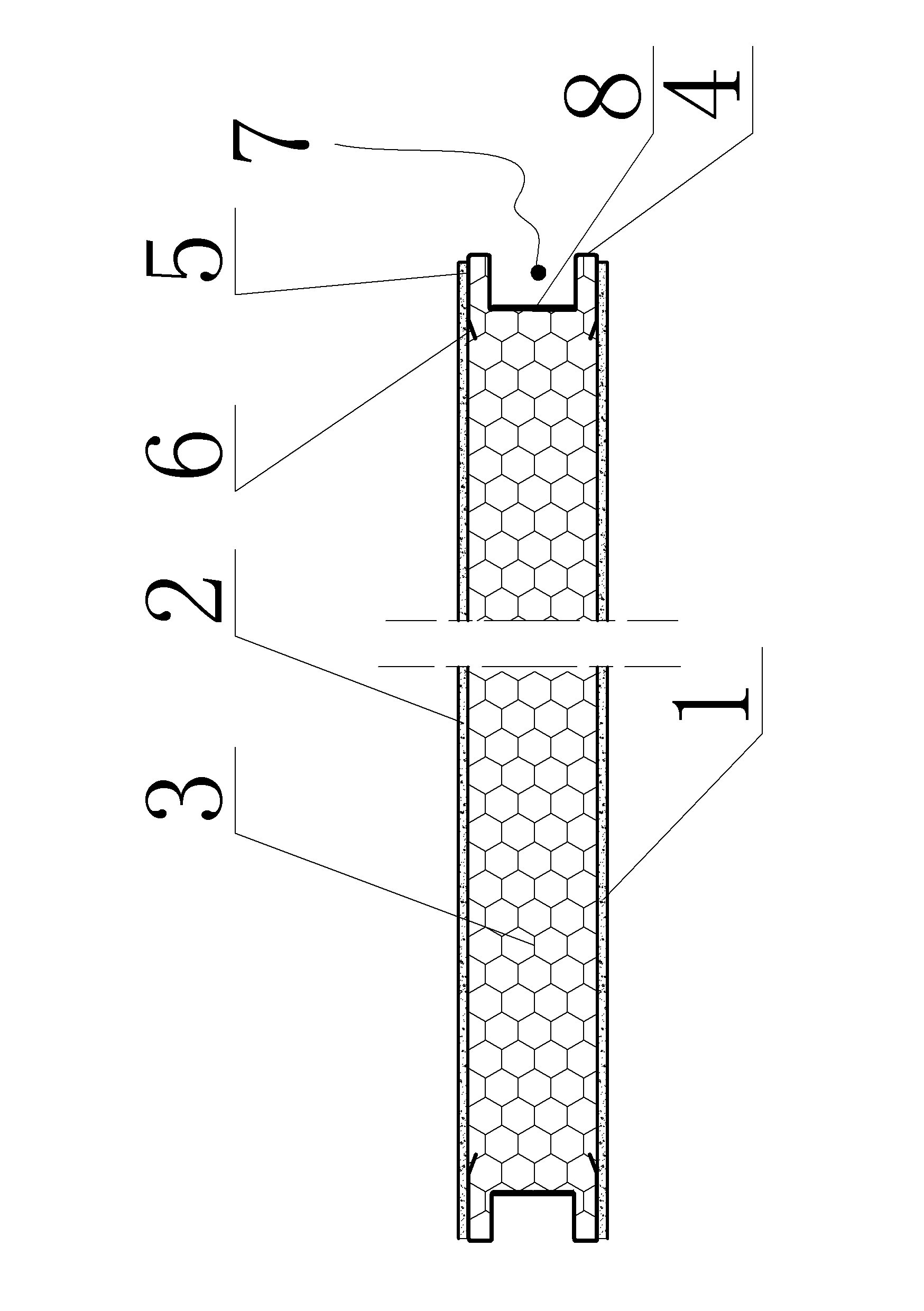

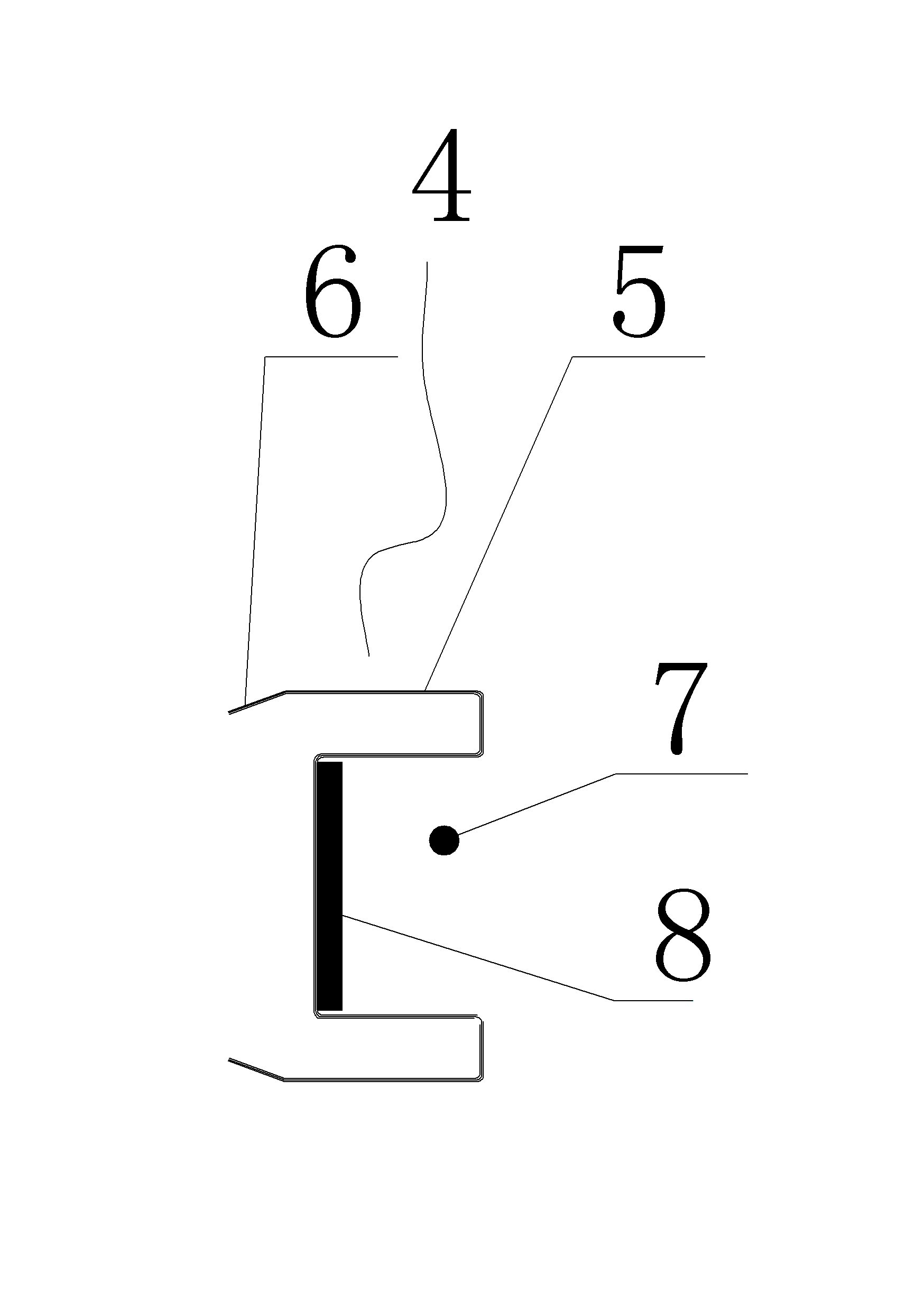

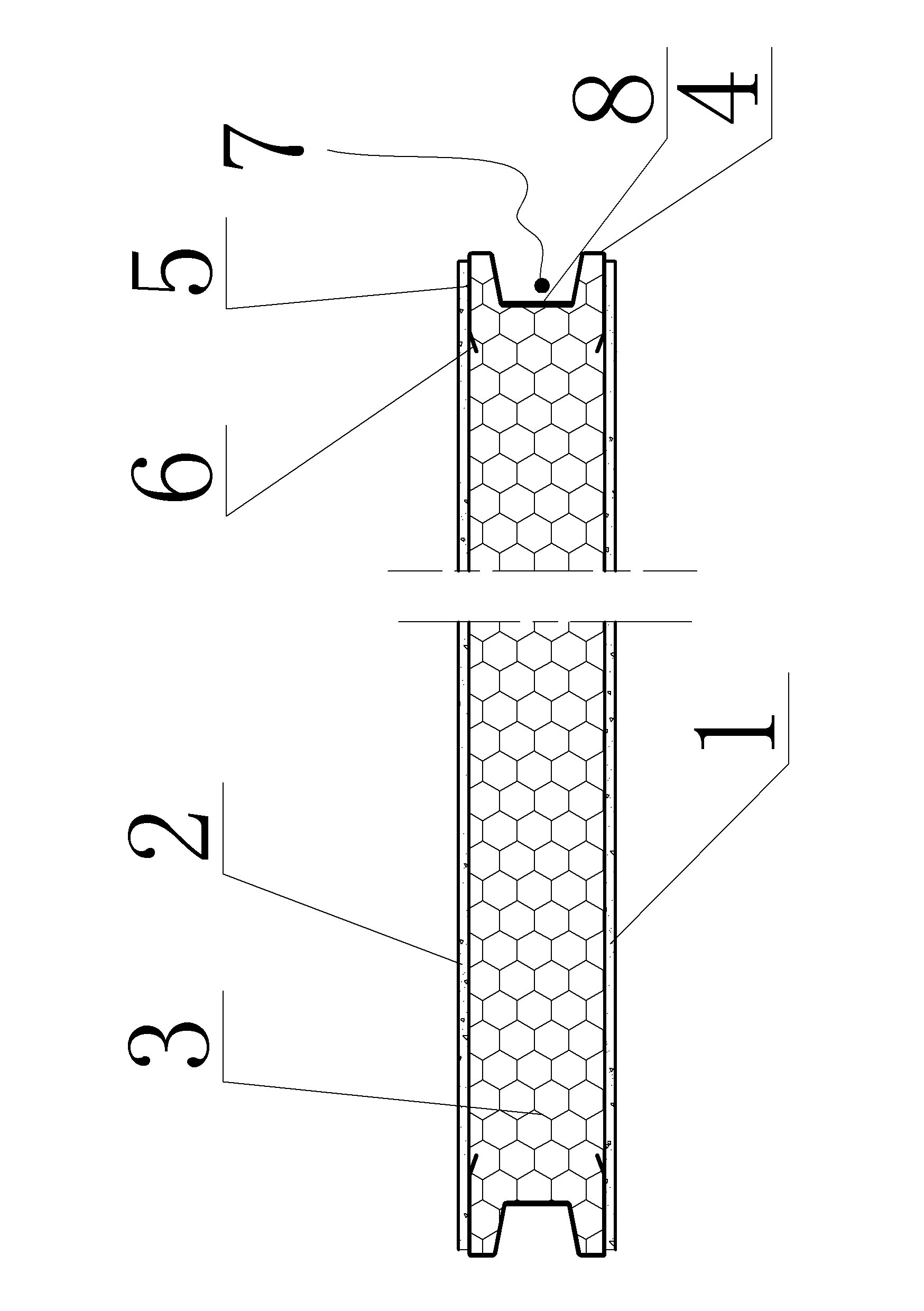

[0029] Embodiment 1 of the composite plate of the present invention, such as figure 1 and figure 2 As shown, it consists of a panel, a foam filling layer 3 and connectors. The panels include an inner panel 1 and an outer panel 2, both of which are made of cement fiber boards; of course, in other embodiments, the inner and outer panels can also be made of hard materials such as fiber-reinforced calcium silicate boards. The foam filling layer 3 is sandwiched between the inner and outer panels, and the foam filling layer 3 is made of modified PIR polyurethane foam with good energy-saving and flame-retardant effects; of course, in other embodiments, other fire-proof and heat-insulating materials can also be used. After foaming, the foam filling layer 3 is press-bonded with the inner and outer panels to form an integrated structure; the connector adopts the female groove-shaped connector 4, and there are two female-groove connectors 4, and the two female grooves Type connectors ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com