22.5-degree square rotary switch

A rotary switch, square technology, applied in the direction of electric switches, electrical components, circuits, etc., can solve the problems that cannot meet the needs of multiple gears, the rotation angle of the knob is large, and the contact state of the reed is difficult to ensure, so as to prolong the life and strength. Lightweight, gear-clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

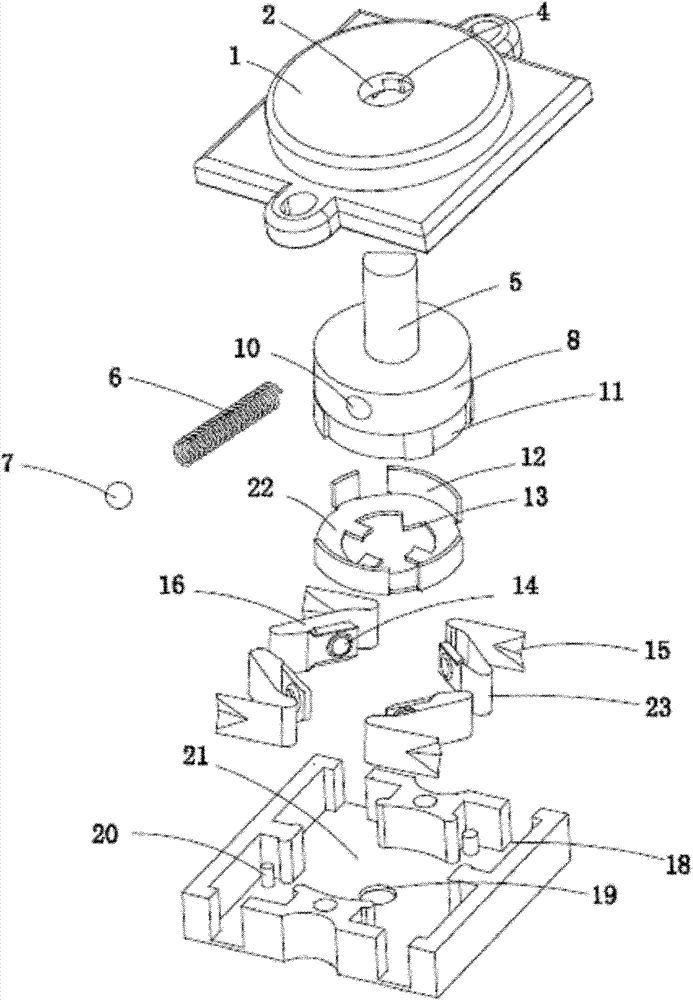

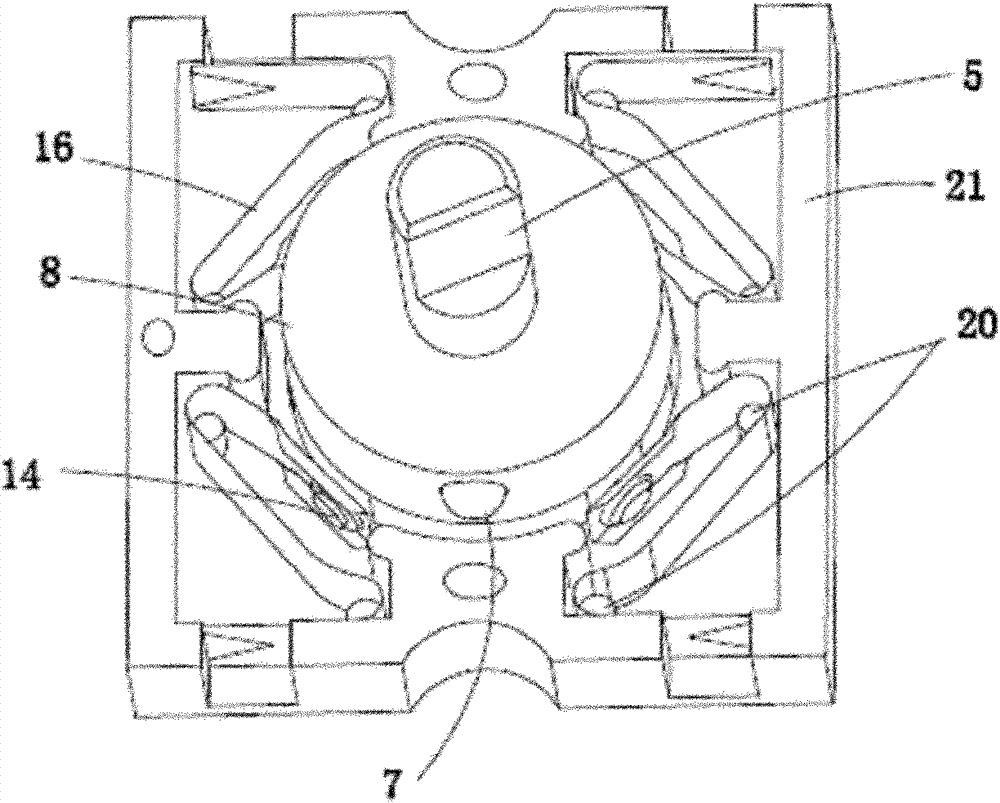

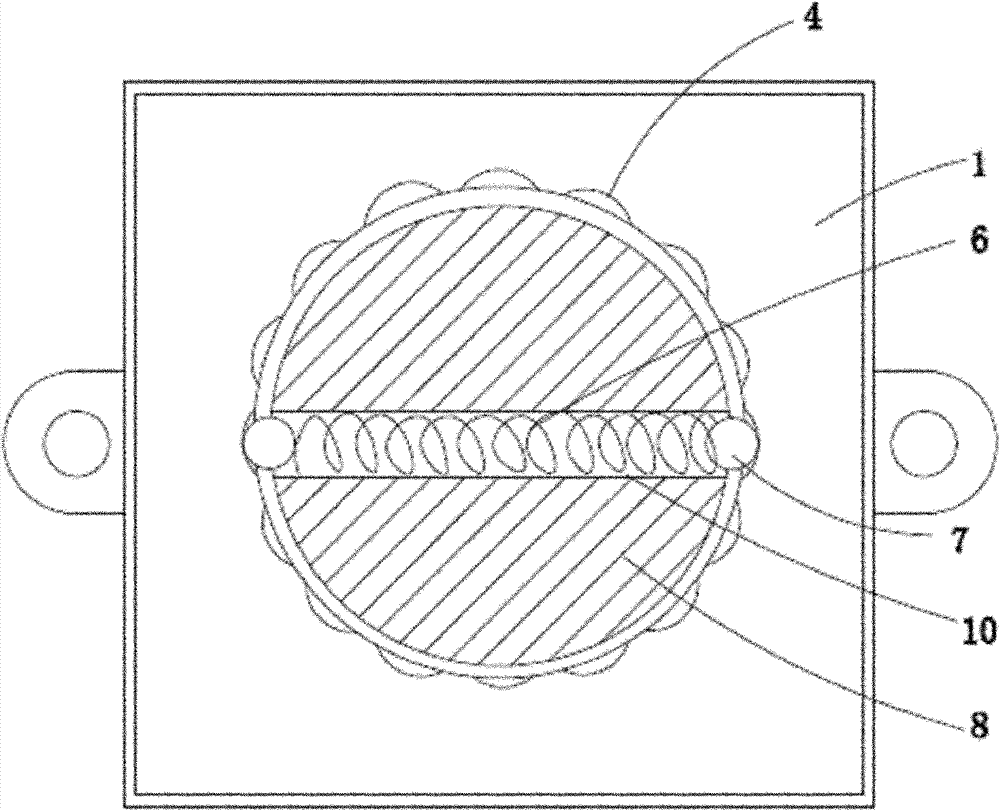

[0019] Such as figure 1 with figure 2 As shown, a 22.5-degree square rotary switch provided in this embodiment includes a cover 1, a knob handle 5, a movable contact piece 22, a reed 16 and a bottom case 21, and a knob seat 8 on the knob handle 5, and a knob seat 8 There is a moving contact slot 11, and the moving contact 22 is provided with a moving contact boss 13 and a moving contact pin 12. The moving contact 22 is mounted on the knob seat 8 and fixed by the moving contact boss 13. , the conductive foot 12 of the movable contact is snapped into the groove 11 of the movable contact, the reed 16 is fixed by the reed fixing pin 20 and arranged in the bottom case 21, and four axially symmetrical reeds 16 are arranged in the bottom case 21 , each reed 16 is provided with a silver contact 14, and each silver contact 14 cooperates with the conductive foot 12 of the movable contact piece; Spring 6, steel balls 7 are provided at both ends of spring 6; knob hole 2 is provided at ...

Embodiment 2

[0020] Such as Figure 5 As shown, the 22.5-degree square rotary switch provided in this embodiment is different from Embodiment 1 in that a limiting boss 9 is provided on the knob seat 8, and the limiting boss 9 fixes the assembly position of the knob seat 8 and the cover 1 and rotation limits.

Embodiment 3

[0022] Such as Figure 4 As shown, a 22.5-degree square rotary switch provided in this embodiment is different from Embodiments 1 and 2 in that a reed wiring groove 15 can be provided on the reed 16, and the reed wiring groove 15 is connected to the bottom shell 21. Wiring notch 18 corresponds, to facilitate external wiring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com