Gas insulated switchgear

A gas-insulated opening and closing and insulation technology, which is applied in the direction of switchgear, switchgear setting, electric switch, etc., can solve the problems of troublesome construction, difficult construction, and difficult bending of copper pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0015] [Configuration of the first embodiment]

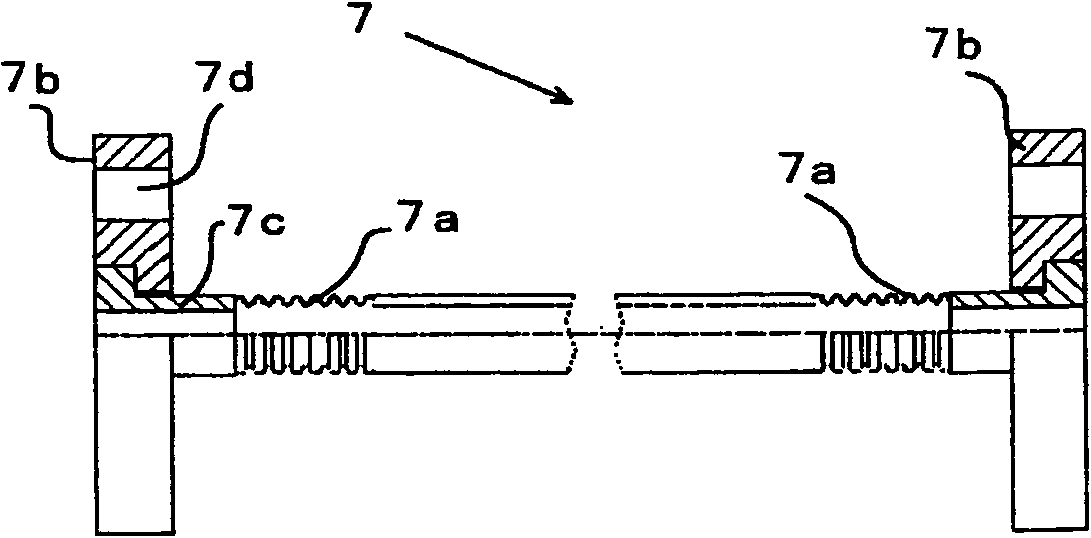

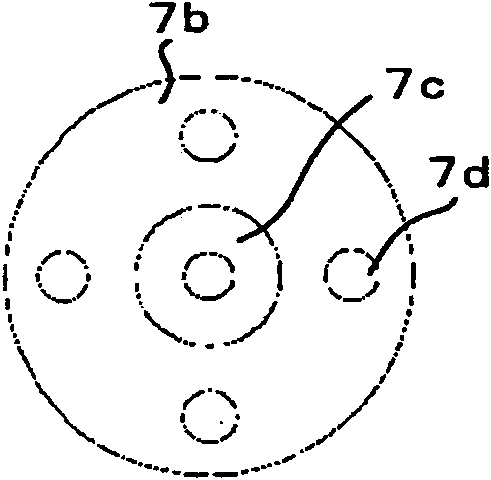

[0016] Below, according to figure 1 , Figure 2A as well as Figure 2B The first embodiment of the present invention will be specifically described.

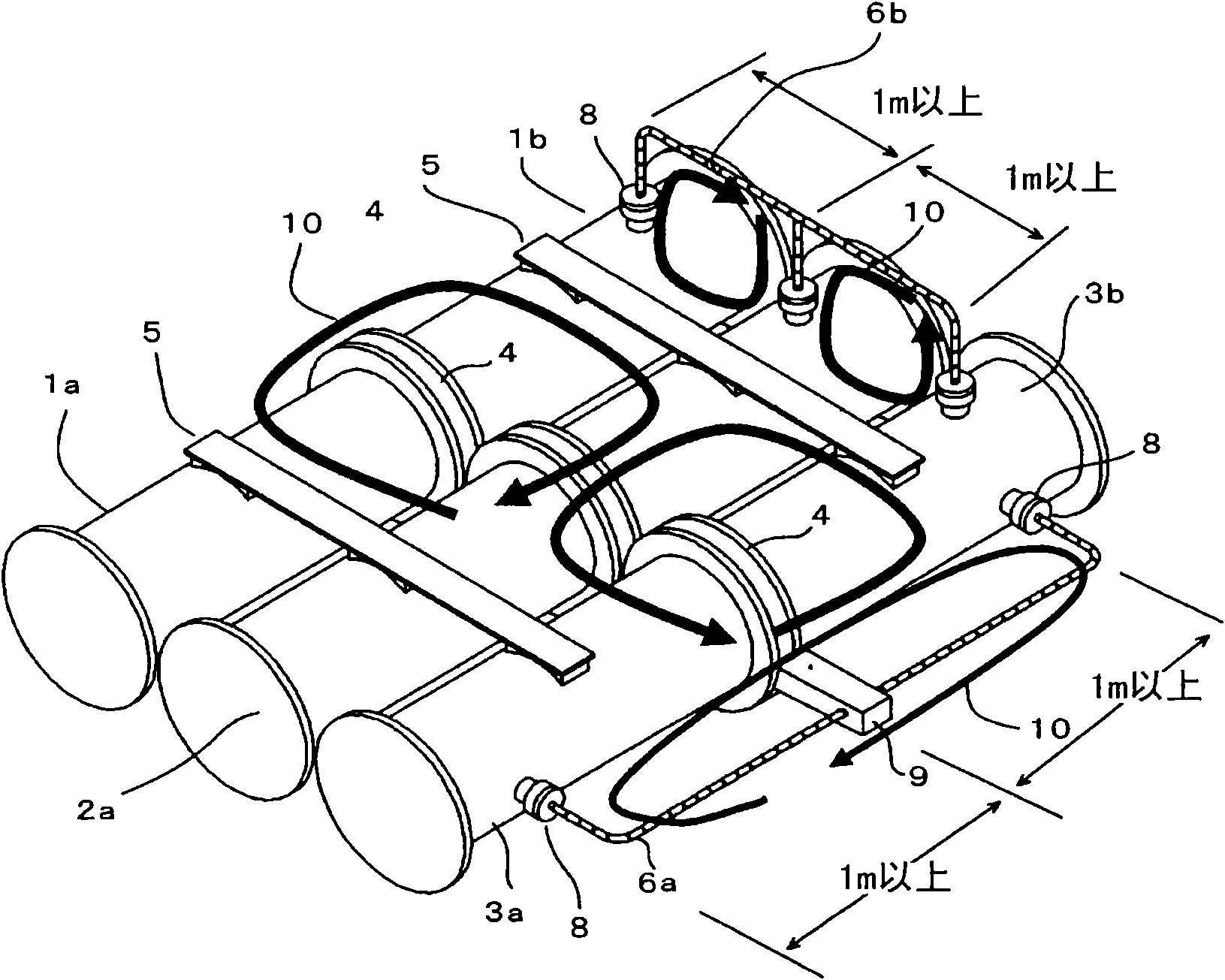

[0017] figure 1 It is a perspective view which shows the position example of the gas piping arrange|positioned between adjacent airtight containers. In the figure, reference numerals 1a, 1b, 2a, 2b, 3a, and 3b denote three-phase airtight containers in which conductors or electrically connected devices are housed, respectively. SF is enclosed in airtight containers 1a, 1b, 2a, 2b, 3a, 3b 6 Gas and other insulating gases. The airtight containers 1 a and 1 b , 2 a and 2 b , and 3 a and 3 b are connected by flanges 4 . The airtight containers of the respective phases are divided by gas at the flange portion 4 as the boundary portion thereof, and direct gas movement does not occur between adjacent airtight containers of the same phase.

[0018] Conductive members 5, 5 extending...

no. 2 example

[0071] according to Figure 3A , Figure 3B , Figure 3C as well as Figure 3D A second embodiment of the present invention will be described. In the gas insulated switchgear 30 of the second embodiment, two main bus bars are connected to one bus bar for a power supply line via a circuit breaker 31 . That is, the gas insulated switchgear 30 includes a three-phase circuit breaker 31, a bus bar 32 for a power supply line connected to one end of each phase circuit breaker 31, a T-shaped connecting bus bar 33 vertically connected to the other end of the circuit breaker 31, The first main bus circuit breaker 34a arranged at the upper end of the T-shaped connecting bus 33 and the second main bus circuit breaker 34b arranged at the other upper end of the T-shaped connecting bus 33 . The devices constituting the gas insulated switchgear 30 are the same as the above-mentioned first embodiment, constituted by an airtight container and a high-voltage device arranged inside, and its i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com