Refrigeration equipment

A technology of refrigeration device and shaft current, which is used in the control of electromechanical transmission devices, refrigerators, refrigeration components, etc., can solve problems such as offset, and achieve the effect of improving the accuracy of the same setting and improving the operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Hereinafter, an embodiment of the present invention will be described with reference to the drawings.

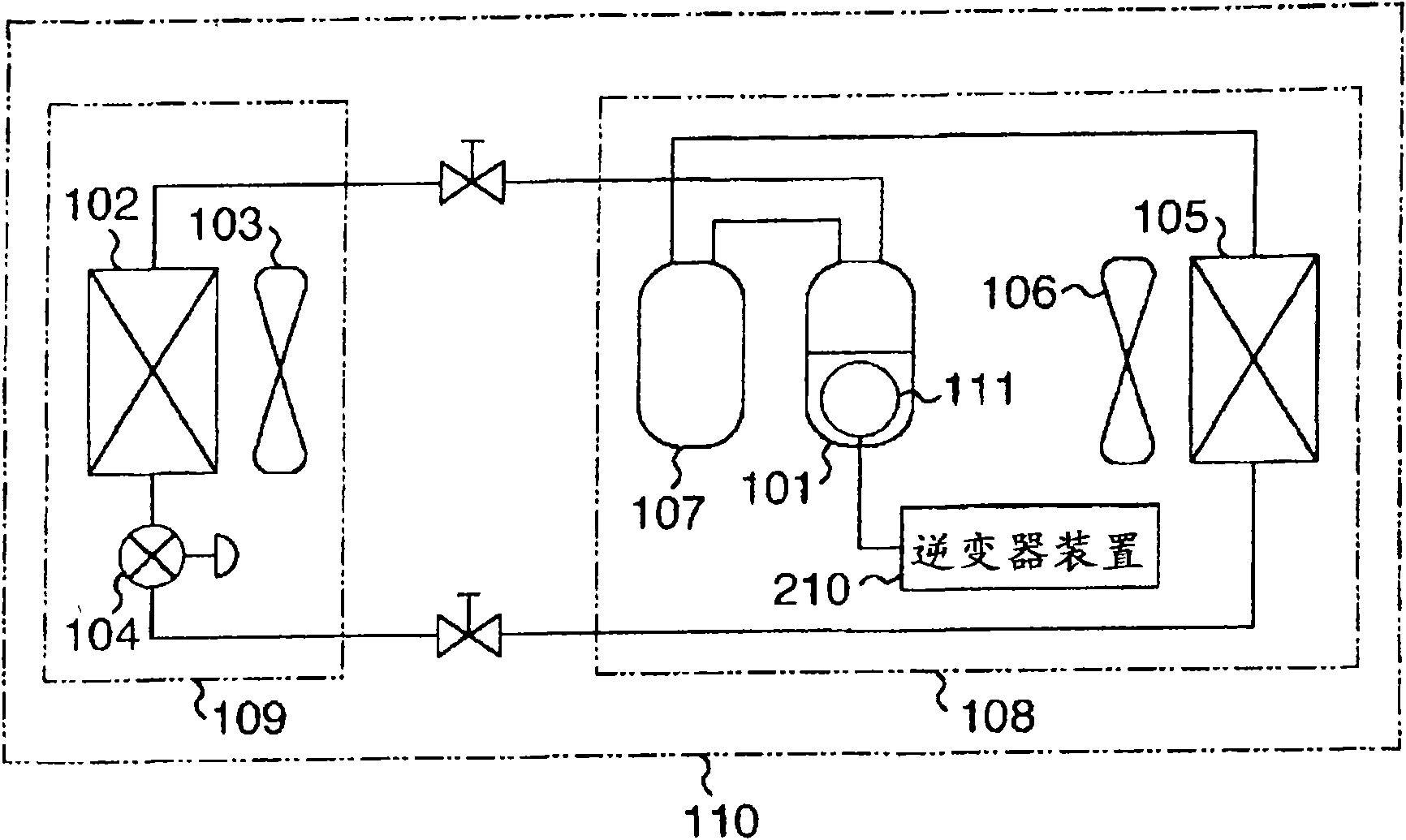

[0026] figure 1 It is a schematic diagram showing the structure of an air conditioner as an embodiment of the present invention.

[0027] At that figure 1 Here, the air conditioner 110 has a refrigeration cycle in which a compressor 101, an indoor heat exchanger 102, an indoor expansion valve 104, an outdoor heat exchanger 105, and an electric storage device 107 are connected in this order. Then, for example, in the case of cooling the room, the refrigerant compressed by the compressor 101 is condensed and liquefied by the outdoor heat exchanger 105, and then decompressed by the indoor expansion valve 104 and evaporated by the indoor heat exchanger 102. And return to compressor 101. In addition, the indoor heat exchanger 102 and the indoor expansion valve 104 are provided in the indoor unit 109, and the indoor unit 109 is provided with an indoor blower 103 for promoting h...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap