Supporting platform for sealing large-span building roofs

A technology of supporting platform and large span, applied in the direction of building, building structure, housing structure support, etc., can solve the problem that rigid rod combination cannot be used, and achieve high strength and rigidity, high safety factor, and reduced interdependence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

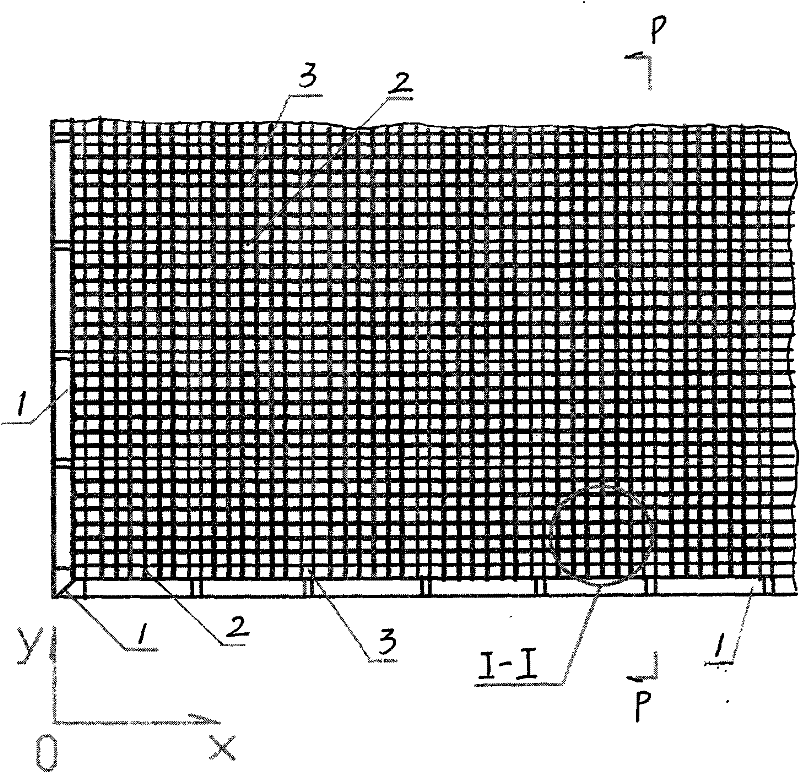

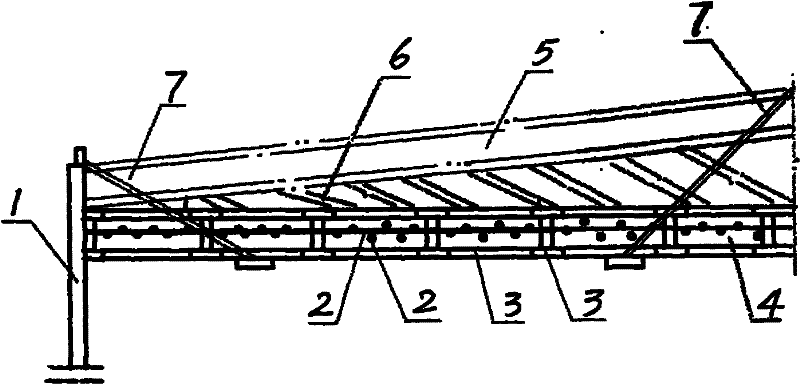

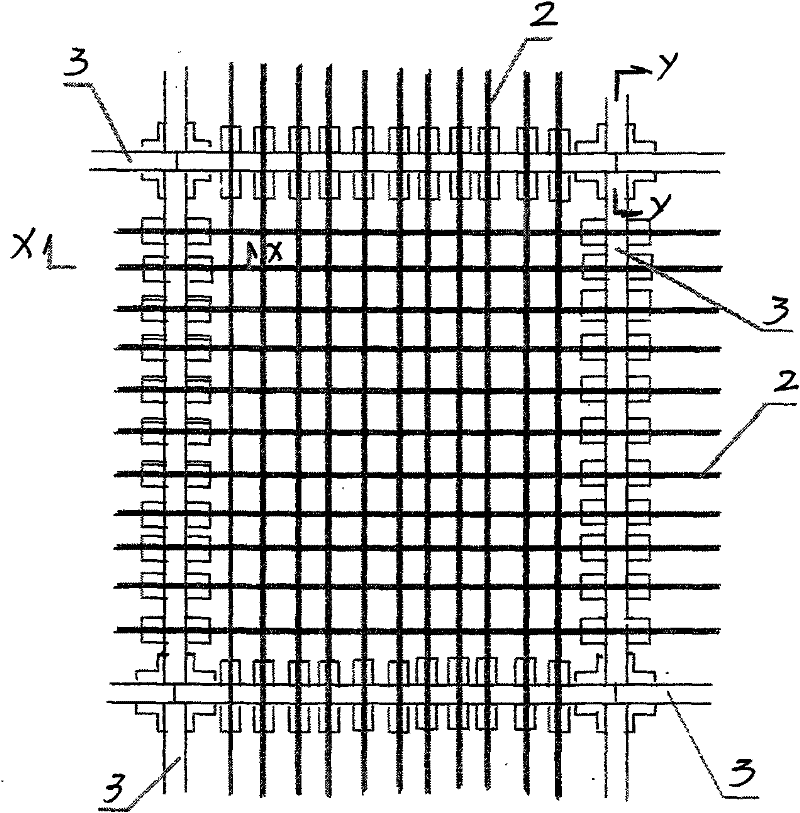

[0026] One, in figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 Among them, trusses 1 are arranged around the construction project, and the trusses are formed by steel materials or reinforced concrete columns with sufficient strength and rigidity. There is no pillar within one meter, and the light beam 3 is made of I63C# aluminum alloy I-beam. Of course, light beams made of other light alloys can also be used. The distance between the light beams in the X direction and the Y direction is 9 meters, and the X direction has There are 30 pitches and 23 pitches in the Y direction, that is, there are 30 light beams in the X direction and 23 light beams in the Y direction. The aluminum alloy I-beams are staggered and fixedly connected to form a skeleton body of 270 meters × 207 meters The strength and rigidity of the truss should be designed and constructed to meet the requirements of the load of the tensioned skeleton body of the steel cables. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com