Different-strength bearing roadway-beside filling body of gob-side entry under coal mine

A technology of retaining entry and filling body, which is applied in the direction of filling, mining equipment, safety devices, etc. It can solve the problems of not satisfying the principle of joint action, etc., and achieve the effects of reducing costs, reducing settlement, and reducing floor bulging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

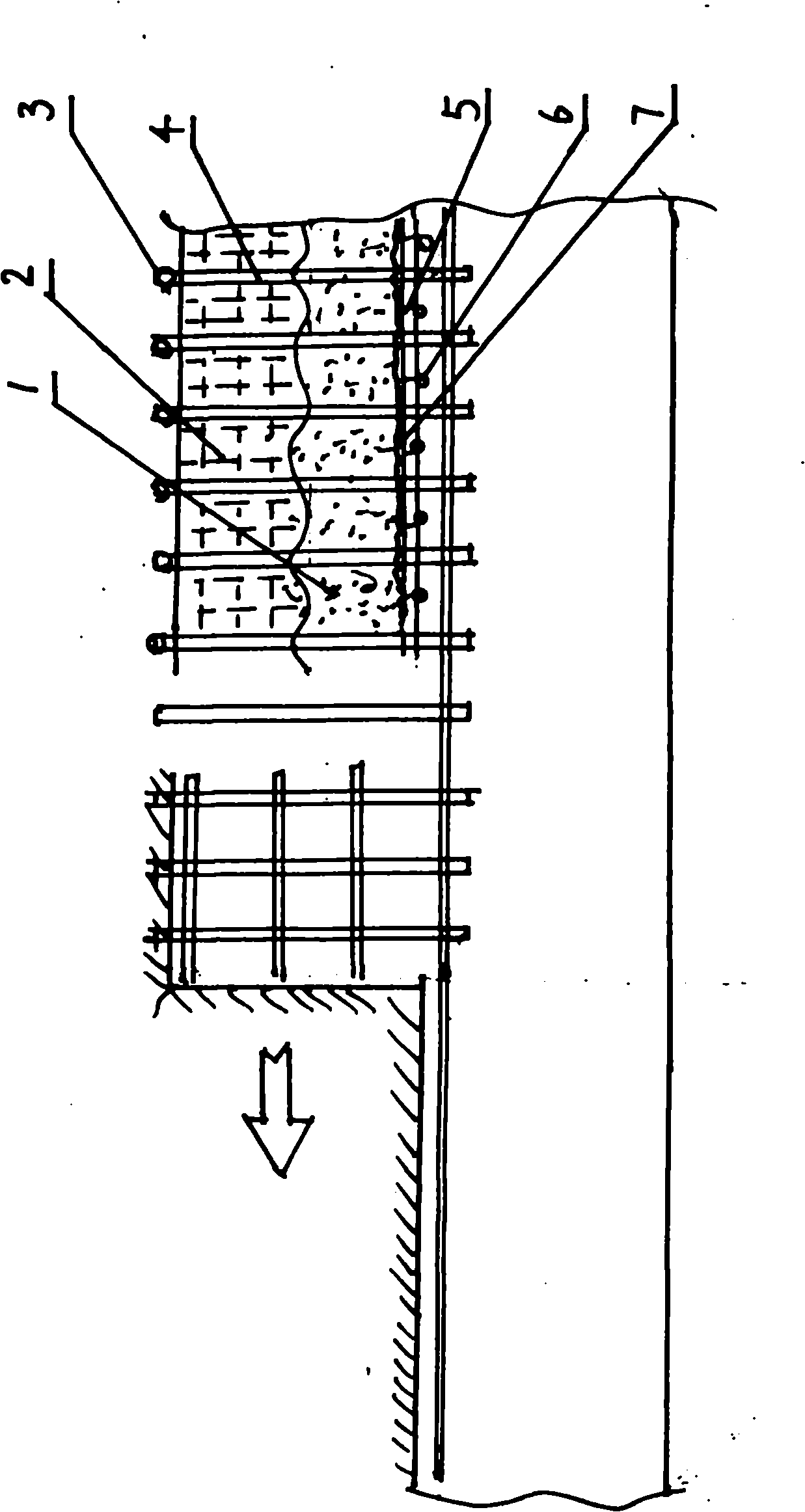

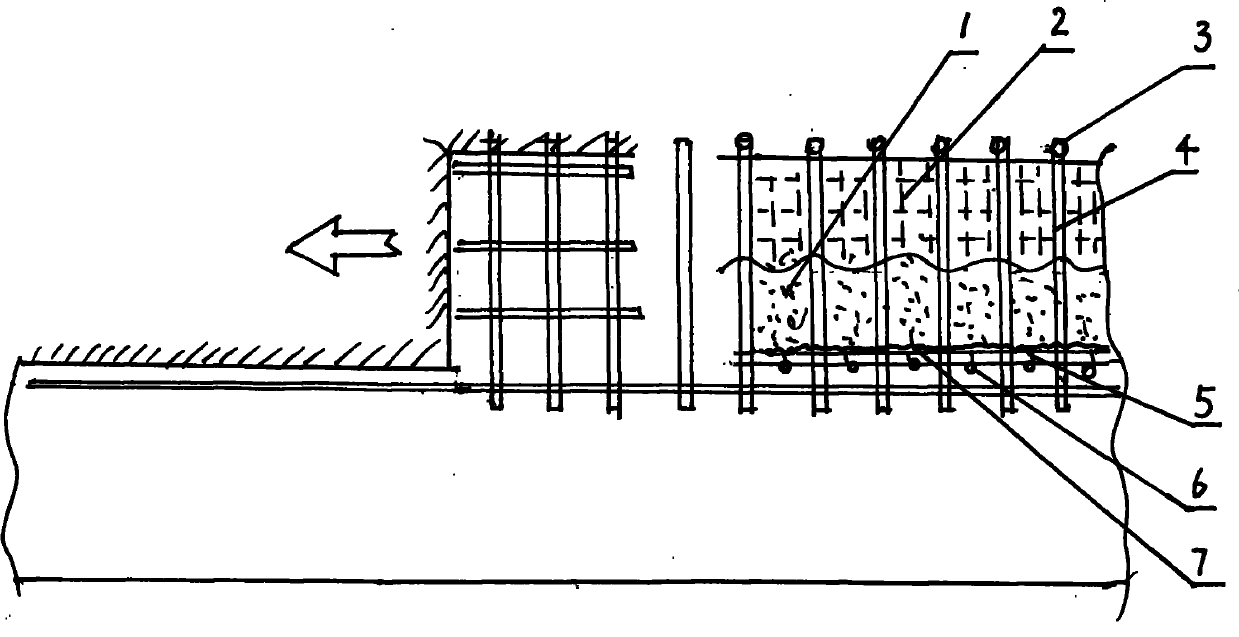

[0016] refer to figure 1 The specific construction method of the supporting body beside the gob-side entry retaining of the present invention is described as follows:

[0017] 1. Construction gangue wall 2

[0018] ①Put the crushed gangue in the woven bag for later use;

[0019] ②Within the 1.5-meter steel belt support range from the lower side of the filling body to the gob, gangue bags are stacked sequentially from the goaf to the tail beam of the support to form a gangue wall 2;

[0020] When stacking gangue bags, it is carried out under the protection of the temporary pillars behind the brackets, and the stacking is carried out as the racks are moved. The unstacked space after the brackets shall not exceed 1.2m.

[0021] Requirements: a. gangue bag pressure seam filling, not hollow, the unfilled space between gangue bags can be filled with crushed floating gangue; b. Between layers of gangue bags, stack them in a criss-cross pattern to ensure the stability of the gangue ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com