Distribution cam for internal combustion engine

A valve cam, internal combustion engine technology, applied in valve details, valve drive devices, etc., can solve the problems of limited cam performance, unfavorable profile optimization design, poor flexibility, etc. smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

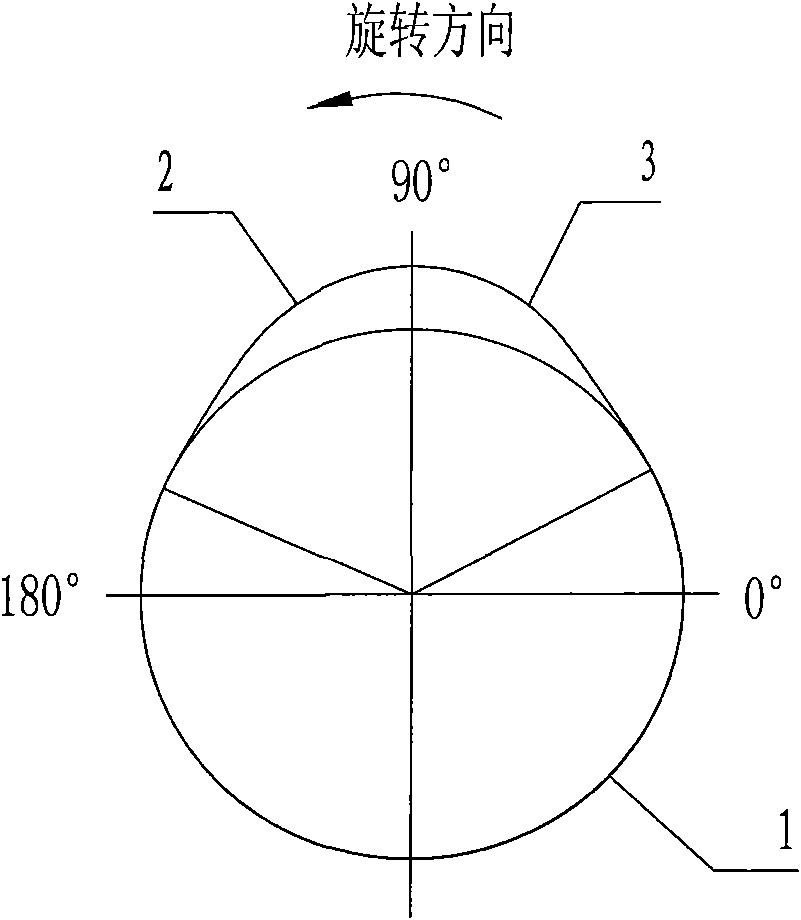

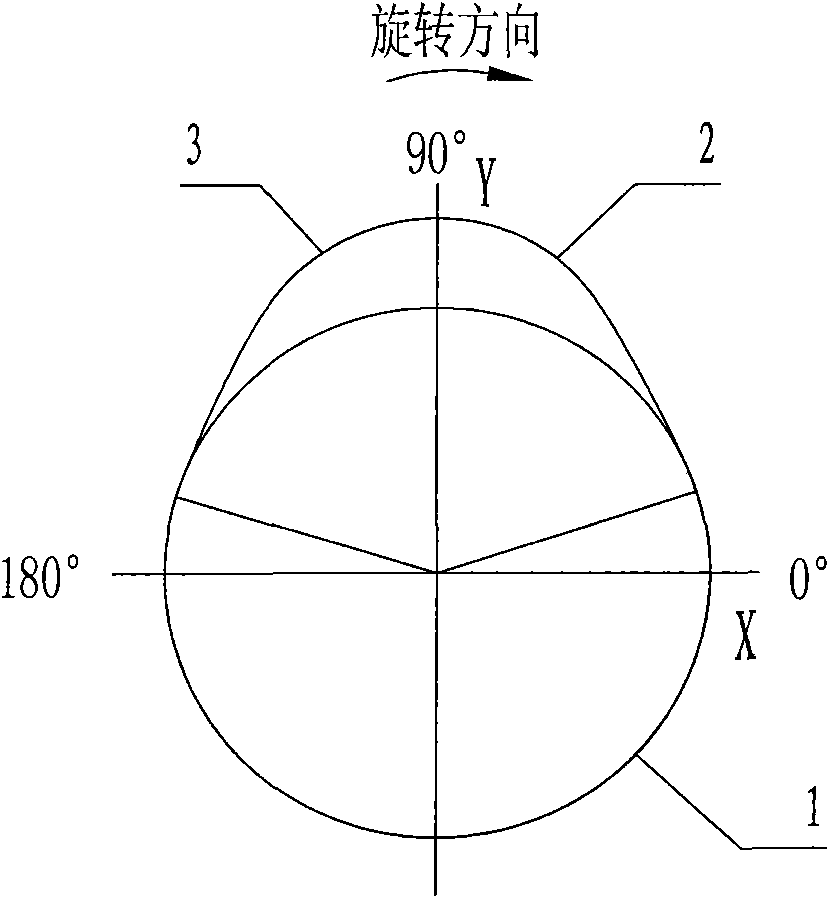

[0058] The invention optimizes the profile design of the cam, improves the performance of the engine, and has the following characteristics:

[0059] 1. The present invention adopts ISAC (subsection acceleration function), these functions are the first-selected method when the cam profile is optimized, and can be applied to any form of valve train cam.

[0060] 2. ISAC can be freely matched with any function, with good flexibility, such as convenient control of positive acceleration width, etc.

[0061] 3. Available acceleration function types: sine function, polynomial, straight line or transition arc.

[0062] 4. The rising edge (or falling edge) is generally divided into 6 to 10 segment functions to determine how to match the general speed value, jerk characteristics, torque characteristics, and the complexity and workload of matching curves.

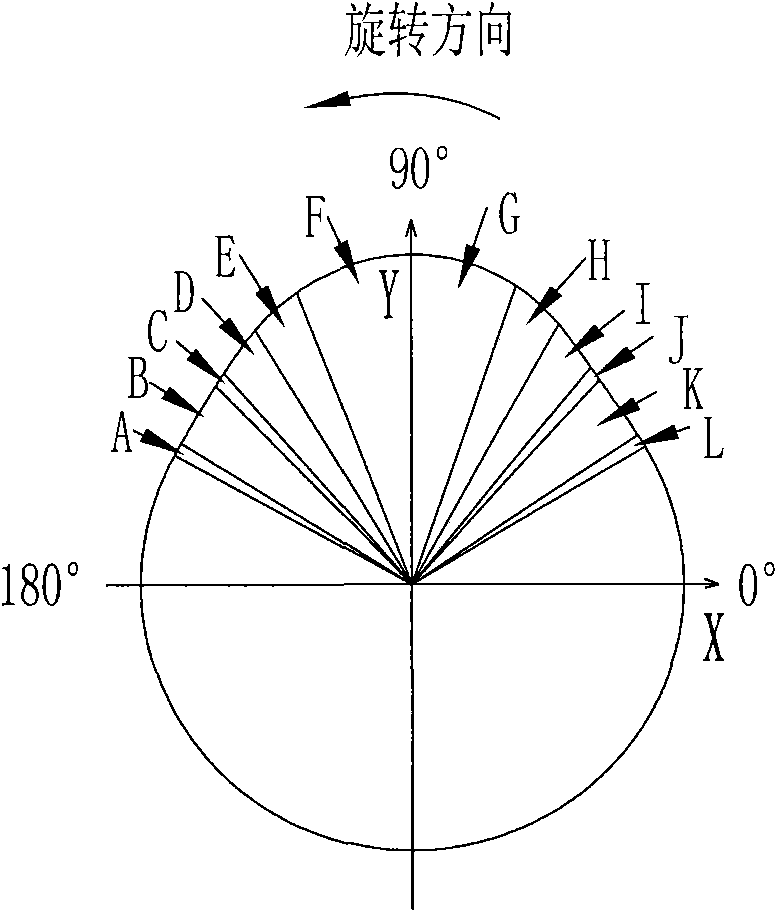

[0063] image 3 The profile line of the intake cam working section shown is composed of 12 functional curves, which are sequentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com