Right-angle solenoid valve for fire control

A solenoid valve, right-angle technology, applied in the field of electric control valves, can solve the problems of easy scaling, unable to change the direction of water flow, difficult to disassemble and wash, etc., to achieve the effect of ensuring connection reliability, preventing residual sediment, and being easy to disassemble and clean

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

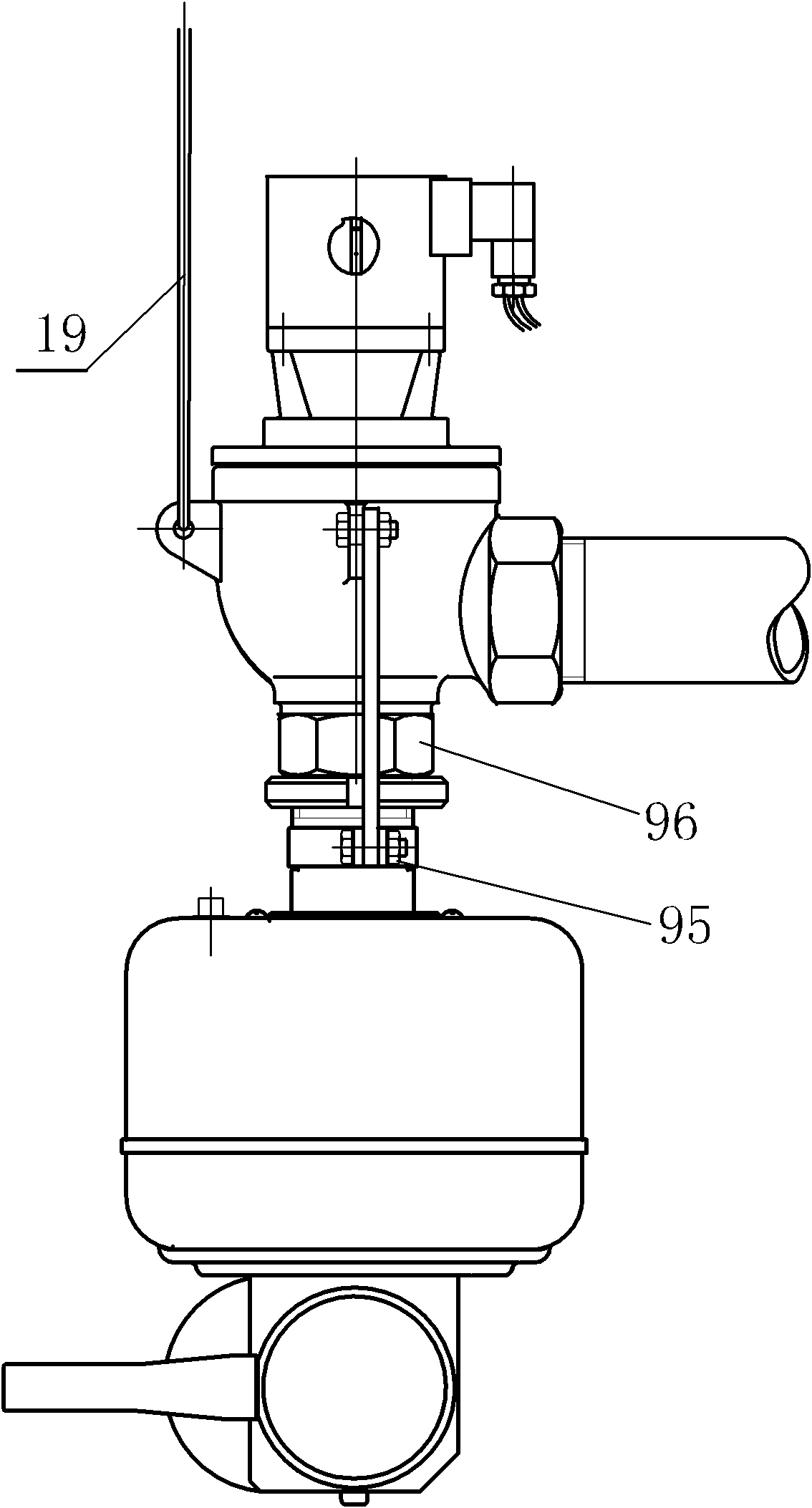

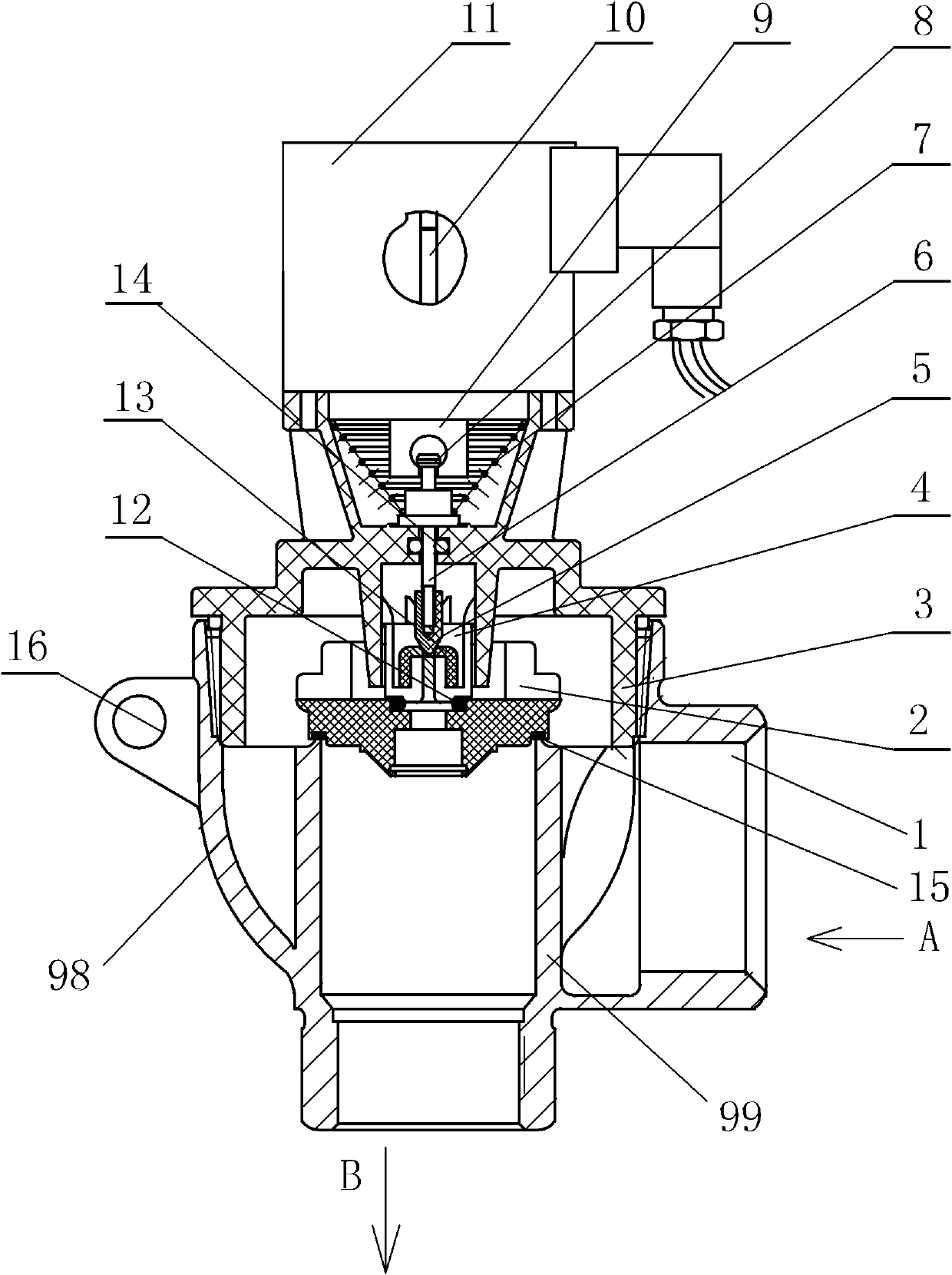

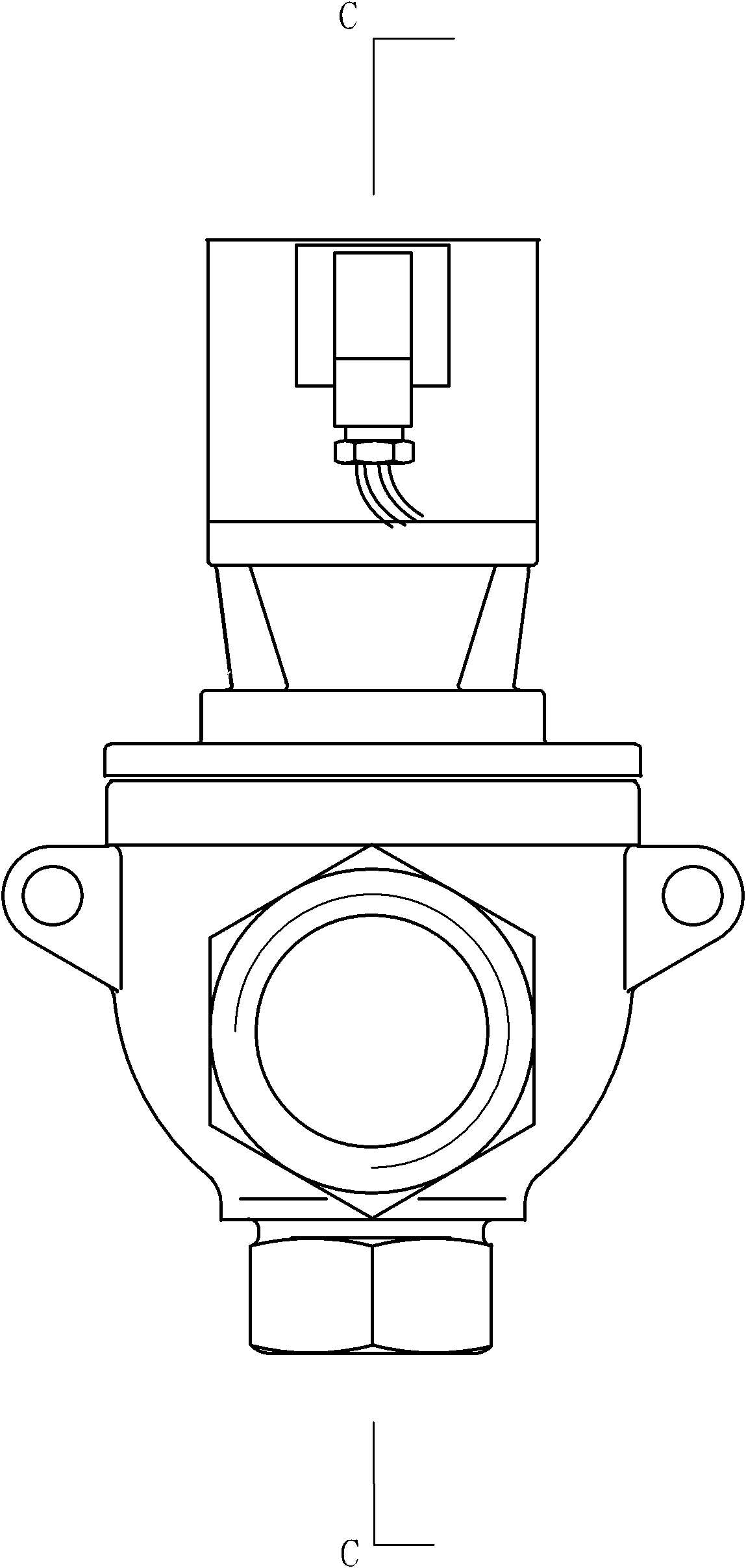

[0018] Such as Figure 1-2 As shown, the right-angle electromagnetic valve of the present invention includes an electromagnetic coil assembly 11, and the electromagnetic coil assembly 11 is at the top of the entire right-angle electromagnetic valve, and a shovel iron guide rod 10 is longitudinally installed in the middle of the electromagnetic coil assembly 11; the electromagnetic coil assembly The bottom of 11 is connected with the upper end of upper cover 3, next to the bottom of electromagnetic coil assembly 11, an inverted truncated cone-shaped return spring 7 is placed inside upper cover 3, and a return spring 7 that can drive return spring 7 is fixed on the inner top of return spring 7. The iron core 9. The lower part of the iron core 9 is provided with a spherical single-mouth groove, and the cylindrical end of the reset valve piston 8 with a small round cake is placed in the groove. On the reset valve piston 8 and expose the bottom end baffle plate of the reset valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com