Balanced coal supply control device of large circulating fluidized bed boiler

A circulating fluidized bed and control device technology, applied in fluidized bed combustion equipment, combustion control, combustion type, etc., can solve the problem of not meeting the self-developed CFB control requirements and not well realizing the balanced control of coal feeding on both sides And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

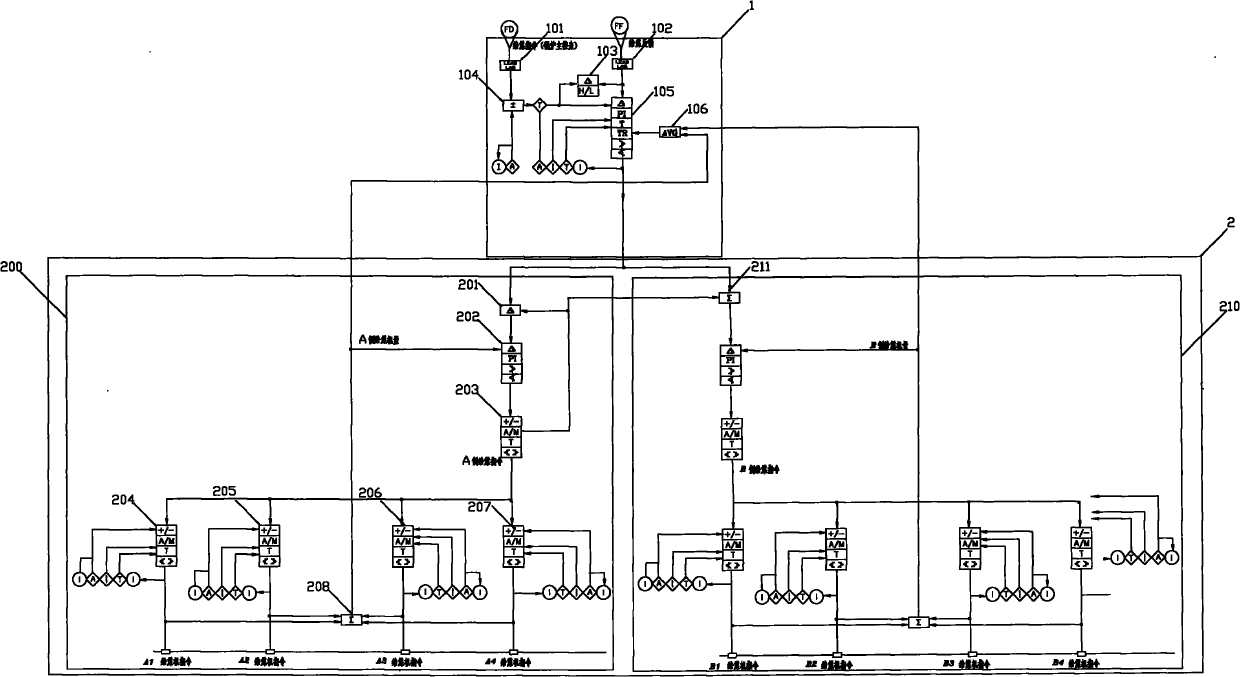

[0019] The self-developed large-scale circulating fluidized bed boiler adopts a single furnace structure with a large width-to-depth ratio, and is equipped with multiple coal feeders for multi-point coal feeding. There are dozens of bed temperature measurement points arranged on the air distribution plate.

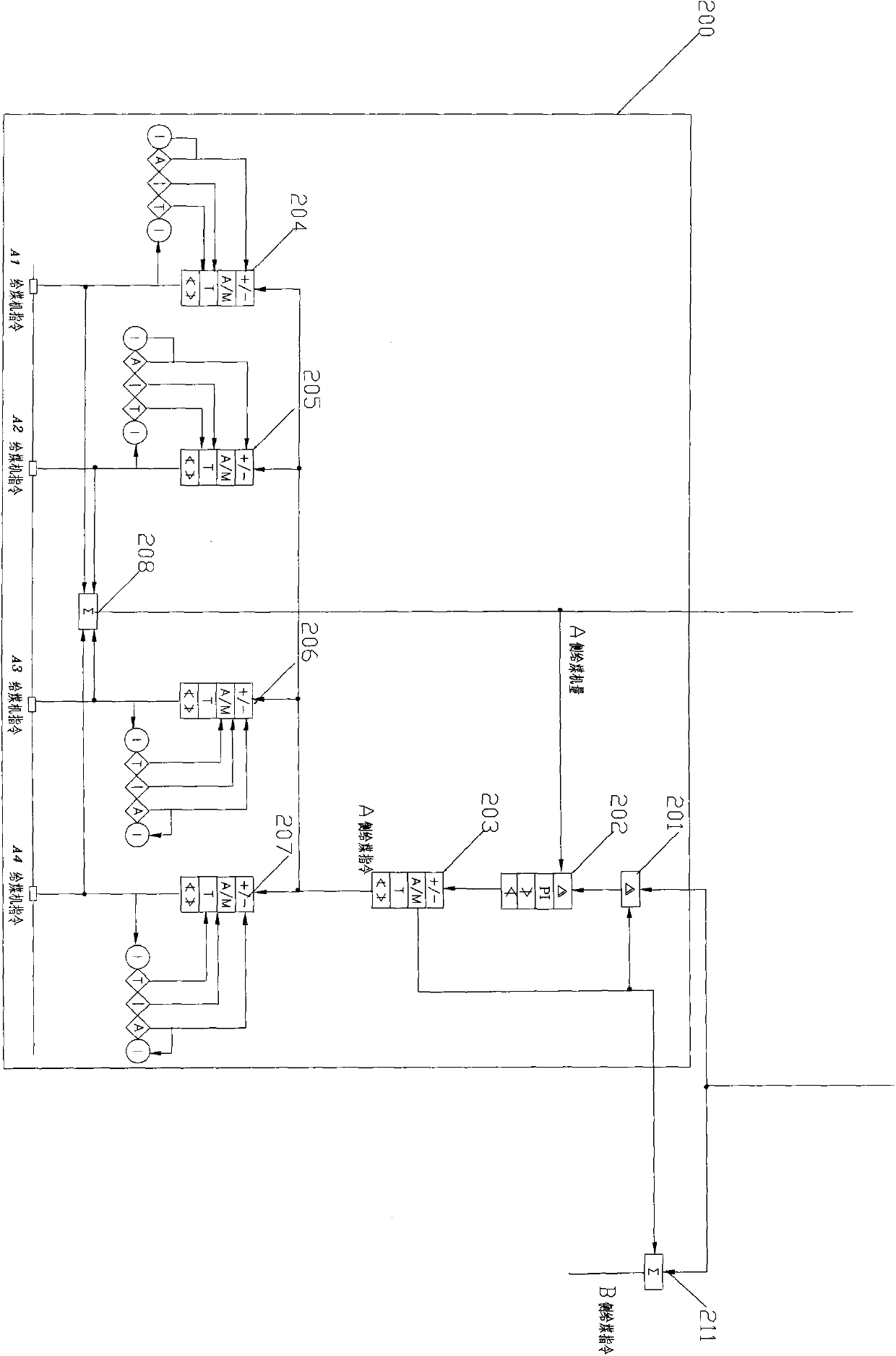

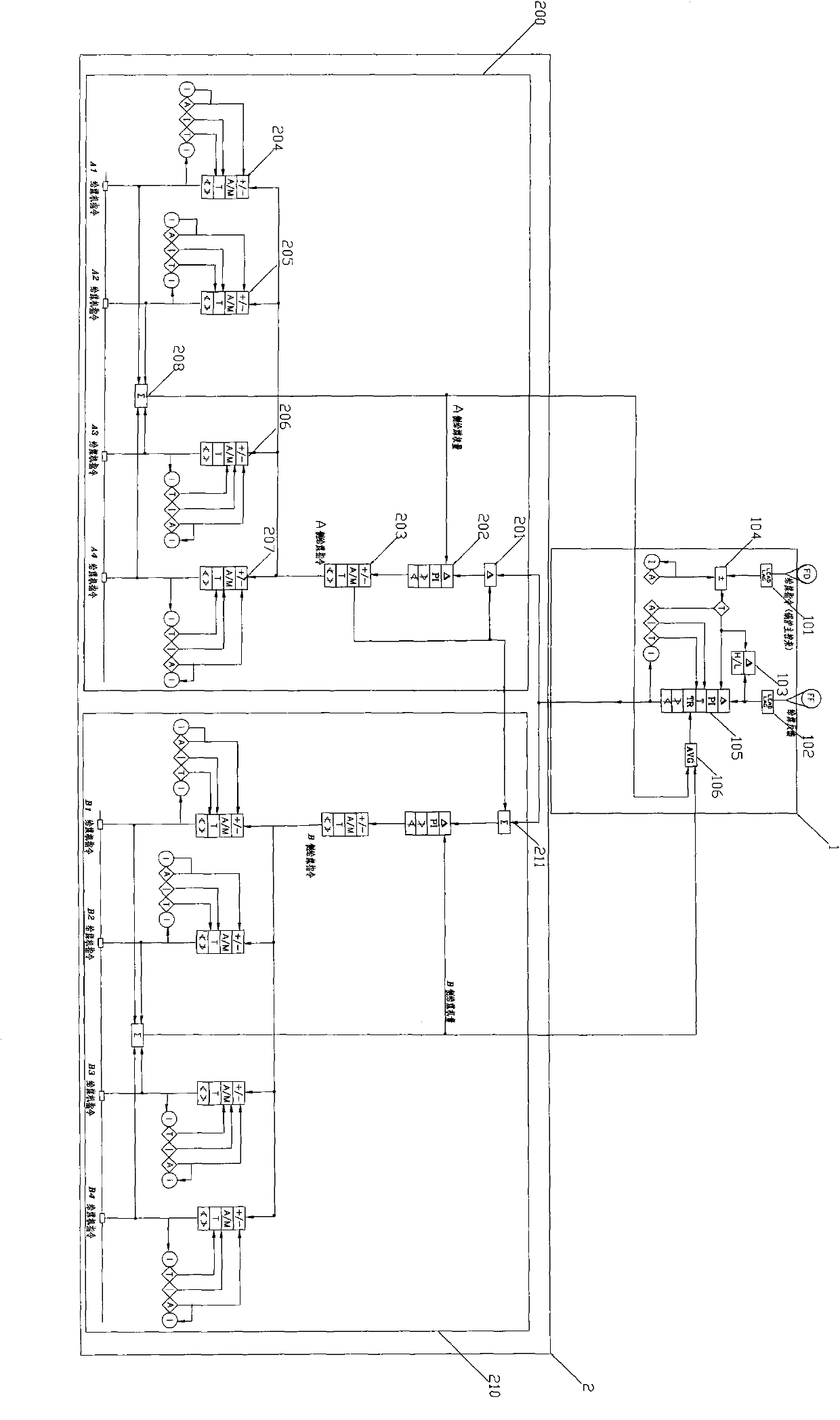

[0020] The best embodiment of the present invention is as Figure 1 to Figure 3 The large circulating fluidized bed boiler balanced coal feeding control device shown includes the coal feeding main adjustment circuit 1 and the coal feeder multi-actuator coordination circuit 2, and the coal feeder multi-actuator coordination circuit 2 includes the circulating fluidized bed boiler A, Balanced coal feeding adjustment loops 200 and 210 on both sides of B, the two sides of circulating fluidized bed boiler A and B represent the left and right sides of circulating fluidized bed boiler, and the coal feeding command signal output by main coal feeding adjustment loop 1 is sent to A an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap