Optical fiber connector and assembly methods thereof

A technology of optical fiber connectors and assembly methods, which is applied in the coupling of optical waveguides and other directions, can solve the problems of poor connection strength and difficulty in fiber penetration, and achieve the effects of low production cost, fewer components, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

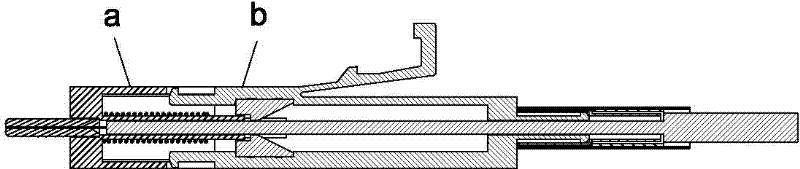

[0036] figure 1 It is a schematic diagram of the cross-sectional structure of the traditional front-to-back assembly of the connector. Most of the traditional connector shells use the assembly structure of the front shell a and the rear shell b. The strength of the joint of the optical fiber connector shell of this structure is poor;

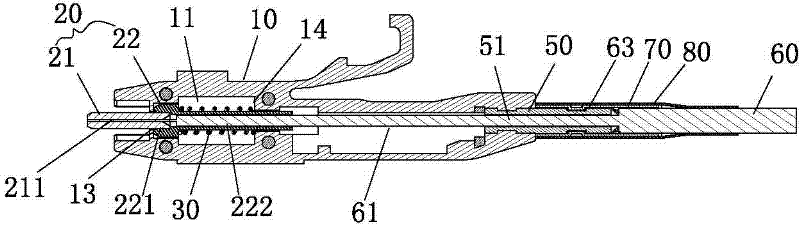

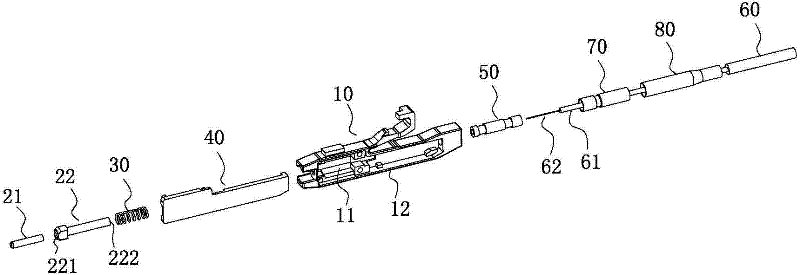

[0037] Figure 2-5 As shown, the content of the present invention is an optical fiber connector, including: a housing body 10, a ferrule assembly 20, an elastic element 30, and a cover plate 40. The housing body 10 has a cavity 11 communicating with the front and back, and the housing body An opening 12 is also provided on the side surface; the ferrule assembly 20 and the elastic element 30 are installed in the cavity 11 through the opening 12 after assembly.

[0038] The ferrule assembly 20 can be formed from one integral part, and can also be composed of a ferrule 21 and a ferrule tailstock 22. A guide hole 222 communicated with the inserti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com