Anti-nuclear radiation semi-flexible/semi-rigid coaxial cable

An anti-nuclear radiation, coaxial cable technology, applied in the field of cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

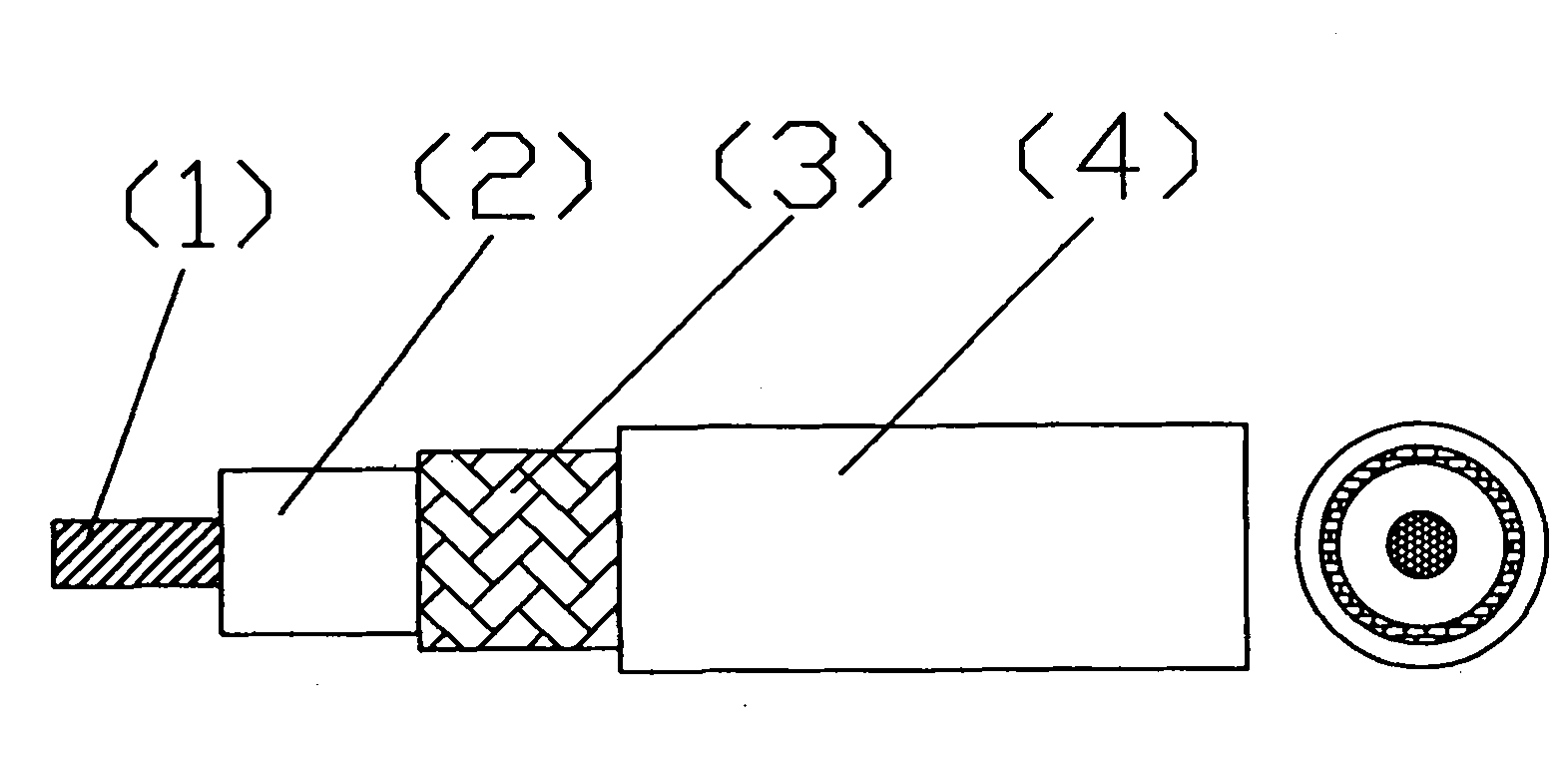

[0035] See attached figure 1 .

[0036] The cable wire of the present invention includes an inner conductor, an insulating layer, an outer conductor and a sheath.

[0037] attached figure 1 For, a polysulfone plastic insulating layer (2) is extruded from a single conductor (1);

[0038] The outer conductor (3) is braided / covered on the insulation layer (2); the outer conductor (3) is extruded with a polysulfone / polyether ether ketone sheath layer (4) as required.

[0039] Inner conductor (1) silver-plated copper wire (SPC), bare copper wire (TPC);

[0040] The insulating layer (2) adopts polysulfone plastic (PSU);

[0041] Outer conductor (3) silver-plated copper wire (SPC) / copper tube (TPP);

[0042] The sheath layer (4) is made of polysulfone (PSU) / polyether ether ketone plastic (PEEK).

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com