Leakage protection socket with reverse wiring and end of life detection function

An end-of-life and leakage protection technology, which is applied to parts of connecting devices, protection switch operation/release mechanisms, switches operated by ground fault current, etc. Compulsory tripping function, electric shock hazard and other issues, to achieve the effect of reasonable connection, simple and reasonable structure, and smooth action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

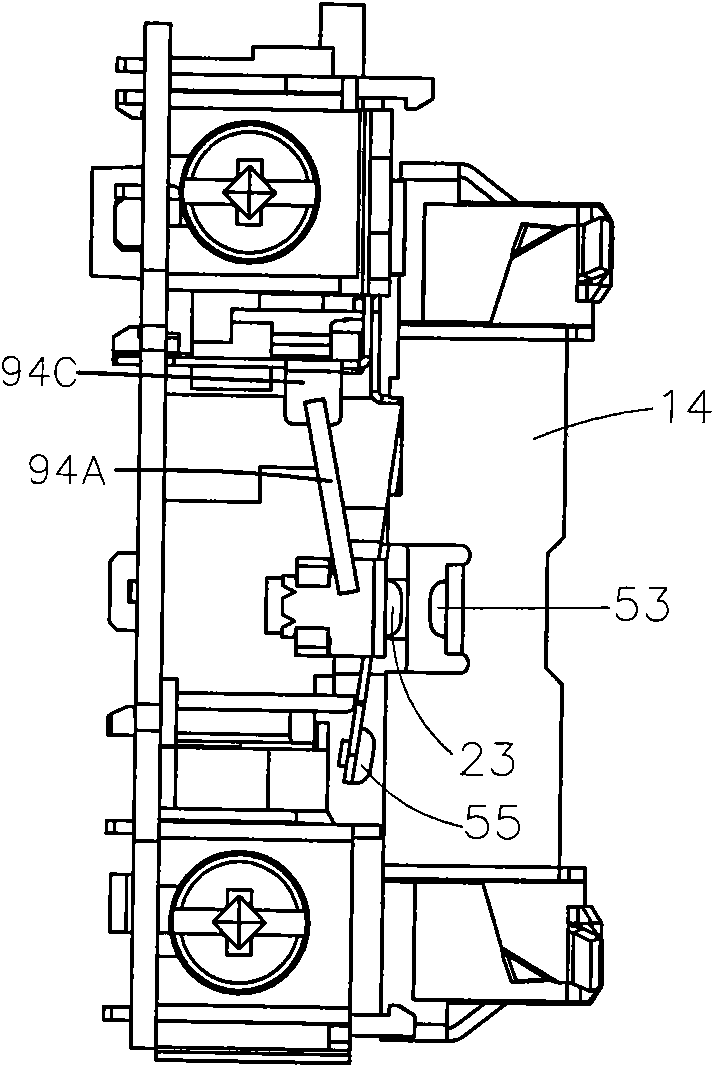

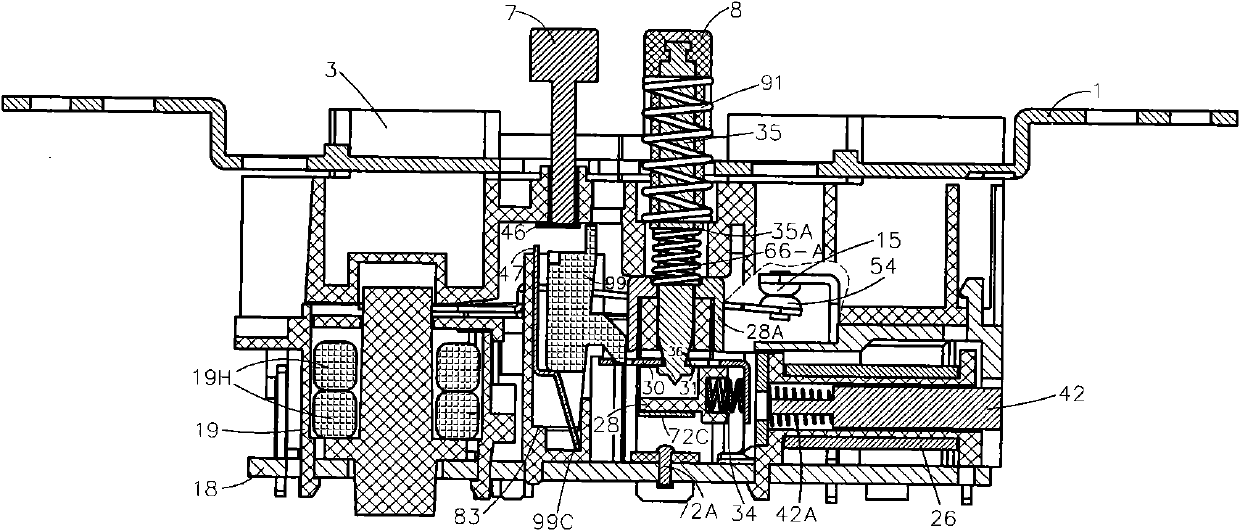

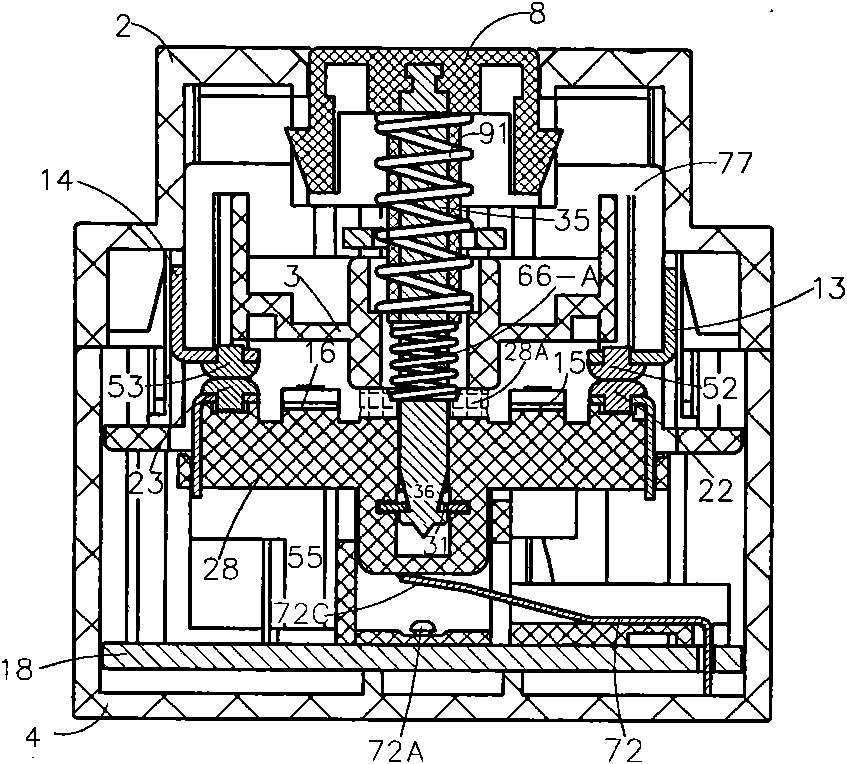

[0037] refer to figure 1 , figure 2 and image 3, the leakage protection socket with reverse wiring and end-of-life detection function of the present invention includes a housing with an output jack, a conductive socket corresponding to the output jack, power input terminals 25 and 24, and power output terminals 81 and 80 , reset / tripping mechanism, leakage current detection circuit, electromagnetic tripping mechanism, analog leakage current generating mechanism and power supply output indicating circuit, the output jack of the present invention is a three-eye jack arranged in a triangle, wherein the grounding hole is a horseshoe-shaped hole, The neutral line hole is a T-shaped hole, and the live line hole is a bar-shaped hole. The live wire and the neutral wire of the power supply input terminals 25, 24 are respectively connected with a dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com