Anti-pollution pin pulling device

A pin puller and anti-fouling technology, which is applied in the direction of suspension/strain insulators, pliers, overhead lines/cable equipment, etc., can solve the problems of difficulty in pulling out pins, small clamping force, and difficult to hold firmly and permanently, and achieve universal Wide range of performance, reliable performance, and complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

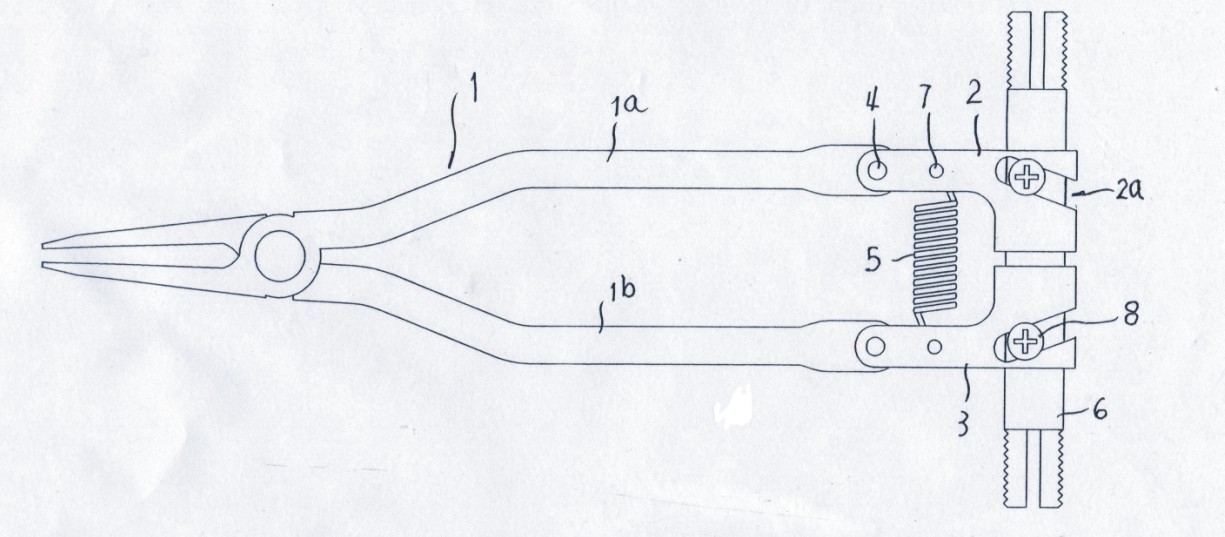

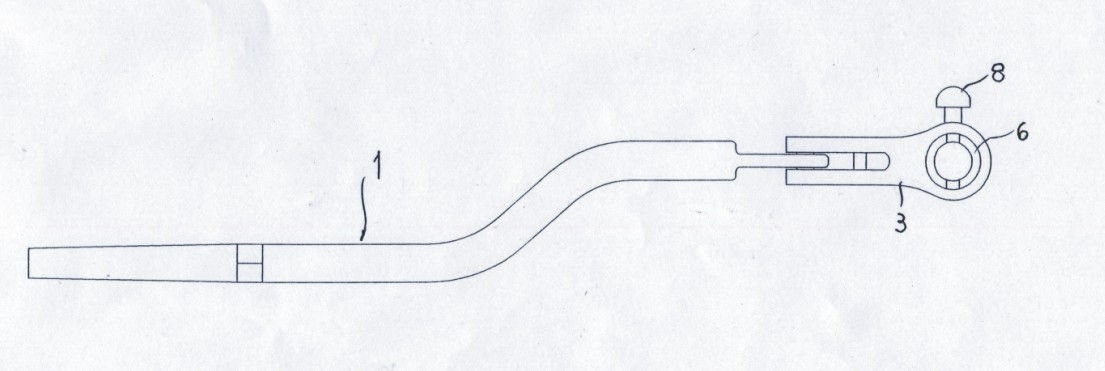

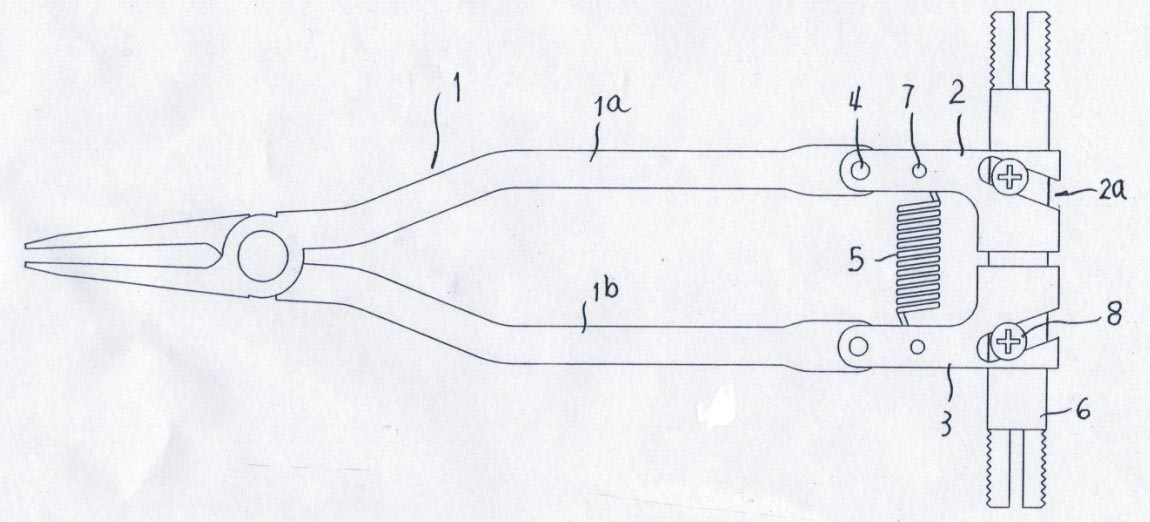

[0014] figure 1 , figure 2 It is shown that the pin puller 1 of the present invention has the same structure, left and right symmetrically arranged left support 3 and right support 2, wherein the right support 2 is formed by welding an lug plate on a pipe joint, and the pipe joint There is a strip-shaped notch 2a; the left and right handles of the pin pulling pliers 1 are curved in a "Z" shape, the left handle 1b of the pin pulling pliers is fixed to the ear plate of the left support, and the right handle of the pin pulling pliers 1a is fixed to the ear plate of the right support, and a tension spring 5 is fixedly connected between the ear plate of the left support and the ear plate of the right support. Among the two pipe joints of the seat, the two outer ends of the connecting pipe 6 protruding from the pipe joints are provided with threads and seams; the connecting pipe is left and right symmetrically screwed with two compression screws 8, and the two compression screws ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com