Modularized combined motor stator structure and application thereof

A motor stator and combined technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve problems such as limited radial strength, high processing accuracy requirements, structural deformation, etc., to reduce manufacturing costs , Improve fault tolerance, improve the effect of slot full rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

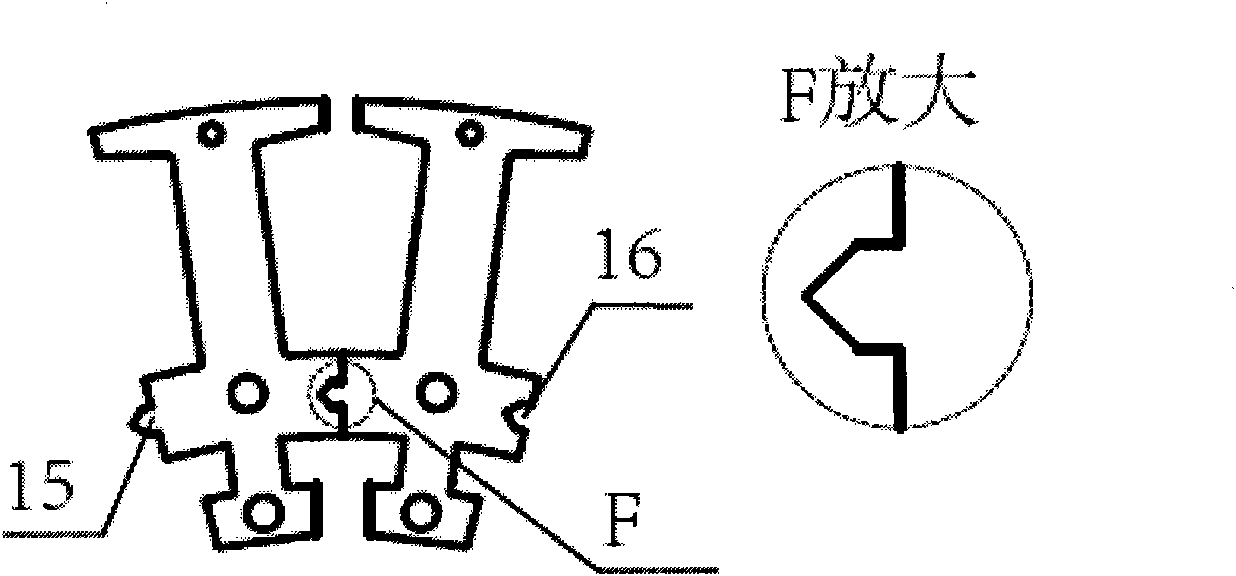

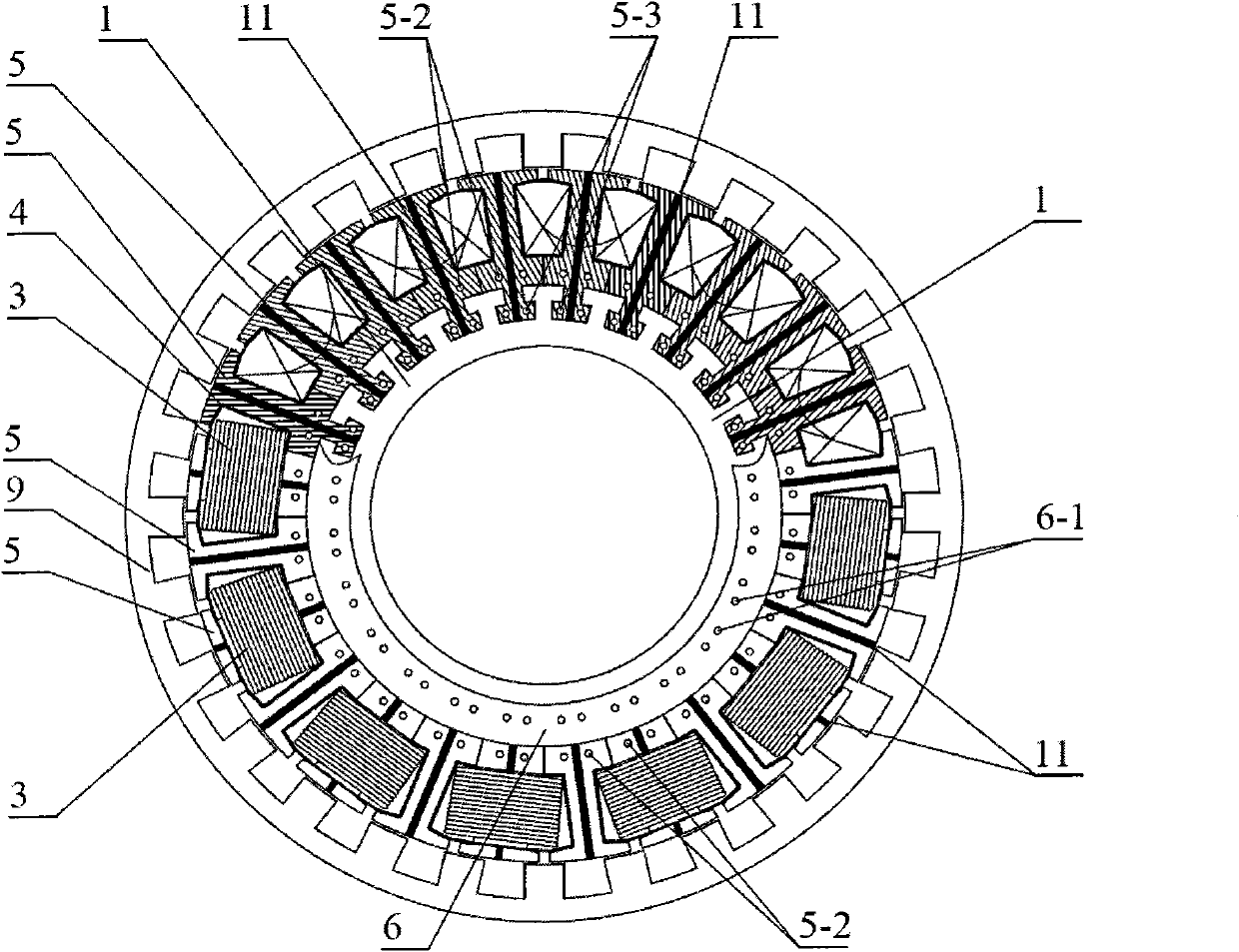

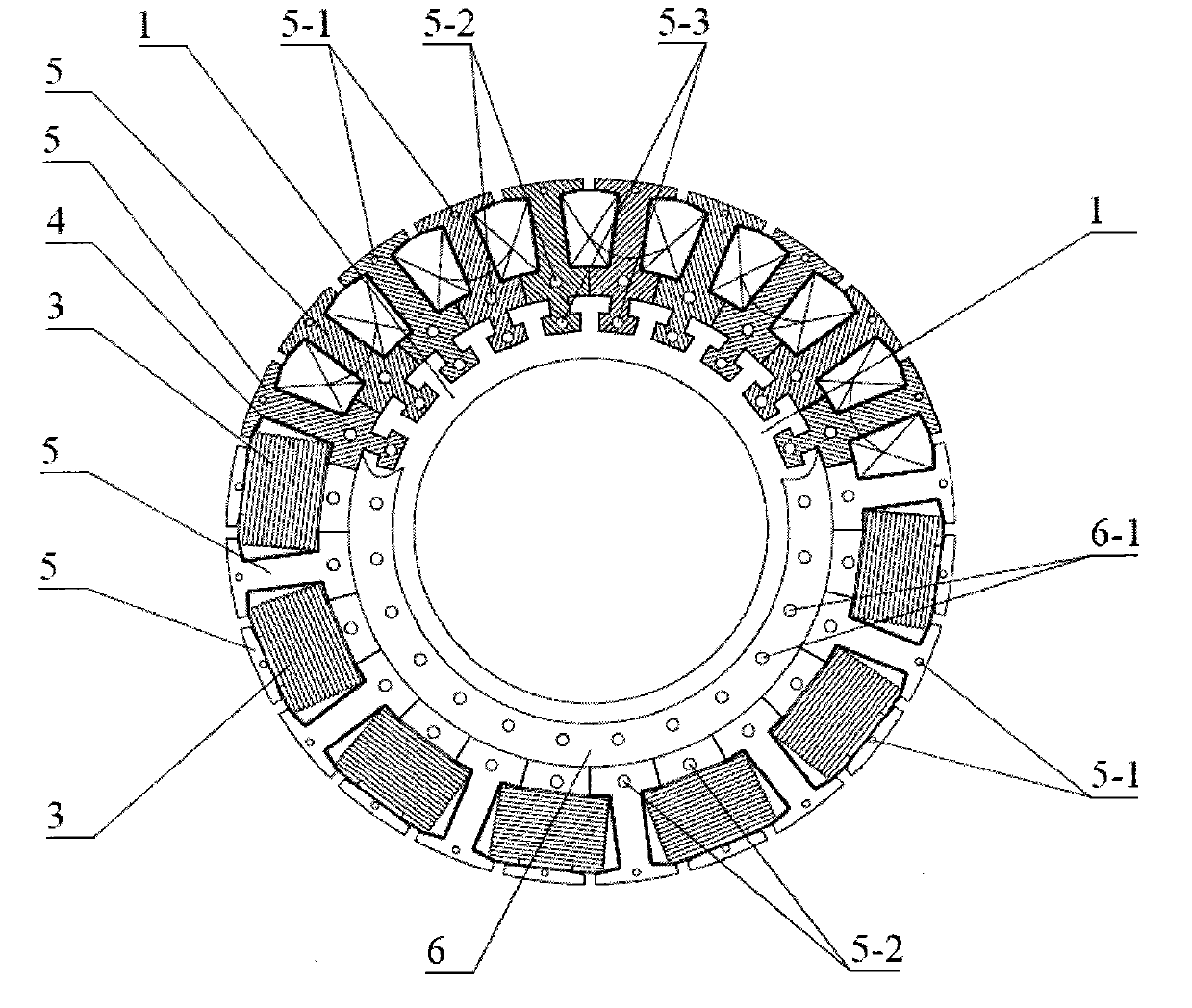

[0025] figure 1 Shown is the modular combined stator structure of the present invention for the outer rotor / inner stator motor, the structure includes: a cylindrical stator support 1 and a stator tooth core 5, the outer surface of the cylindrical stator support 1 is evenly distributed with bottom width , The narrow "T" groove at the opening, the stator tooth core such as figure 2 As shown, it includes crown a, tooth body b, tooth yoke c and tooth root d. The stator tooth core 5 is formed by lamination and fastening of stator tooth punching sheets. In the illustrated example, there is a through hole 5- 1. There is a through hole 5-2 on the yoke c, and the stator tooth core 5 is fastened by fasteners passing through the through hole 5-1 on the tooth crown a of the stator tooth punch and the through hole 5-2 on the tooth yoke c ; Or the stator tooth core 5 can also be fastened by the crown and the rivet buckle on the tooth yoke. The dedendum d of each stator tooth core 5 is pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com