Mask cushioning and forehead pad for a respiratory mask, respiratory mask, manufacturing mould and method for producing the same

A breathing mask and mask technology are applied to a sealing structure and used to manufacture the sealing structure, a molding tool for manufacturing such a breathing mask, and the field of breathing masks, which can solve problems such as problems and achieve the effect of low Shore hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

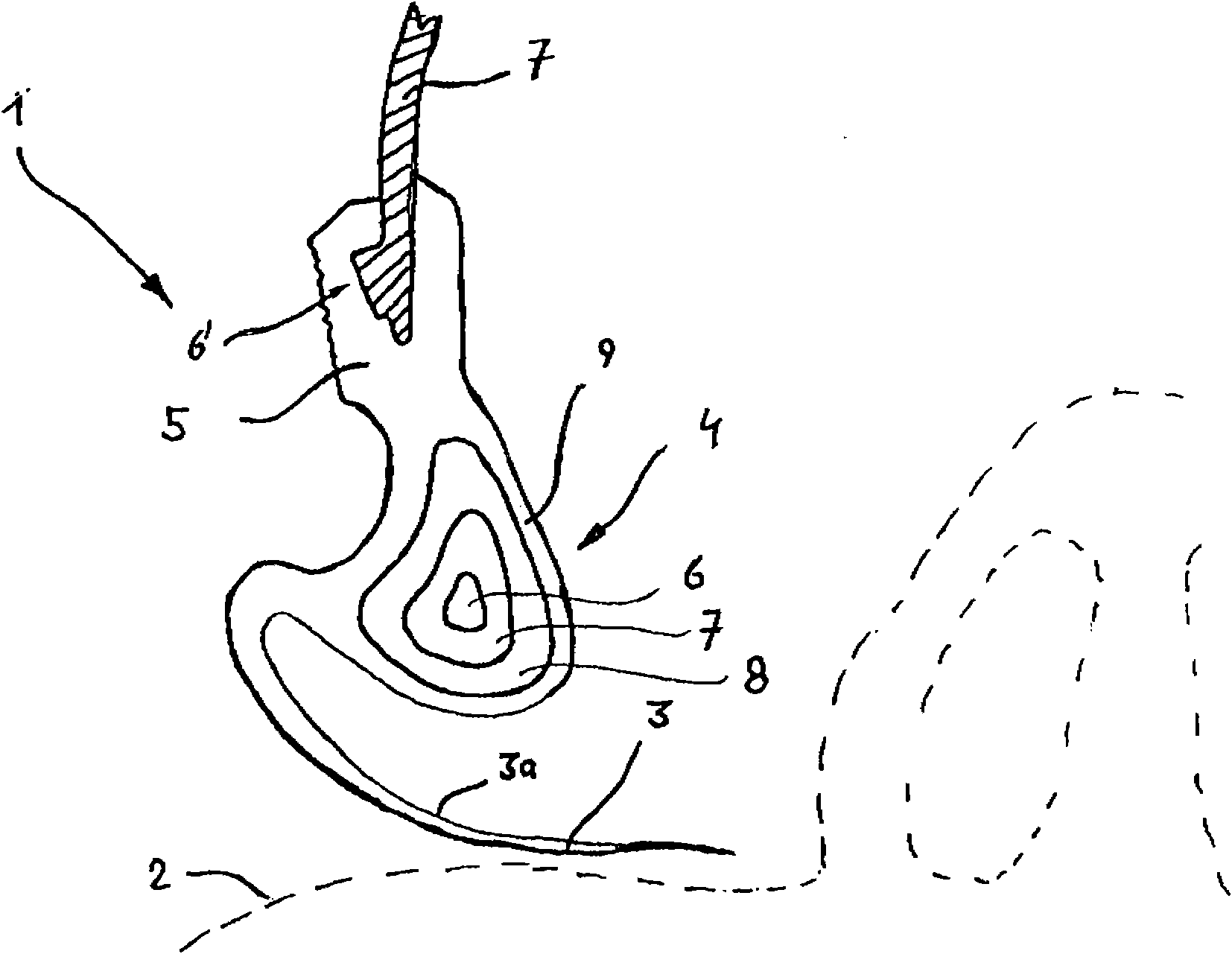

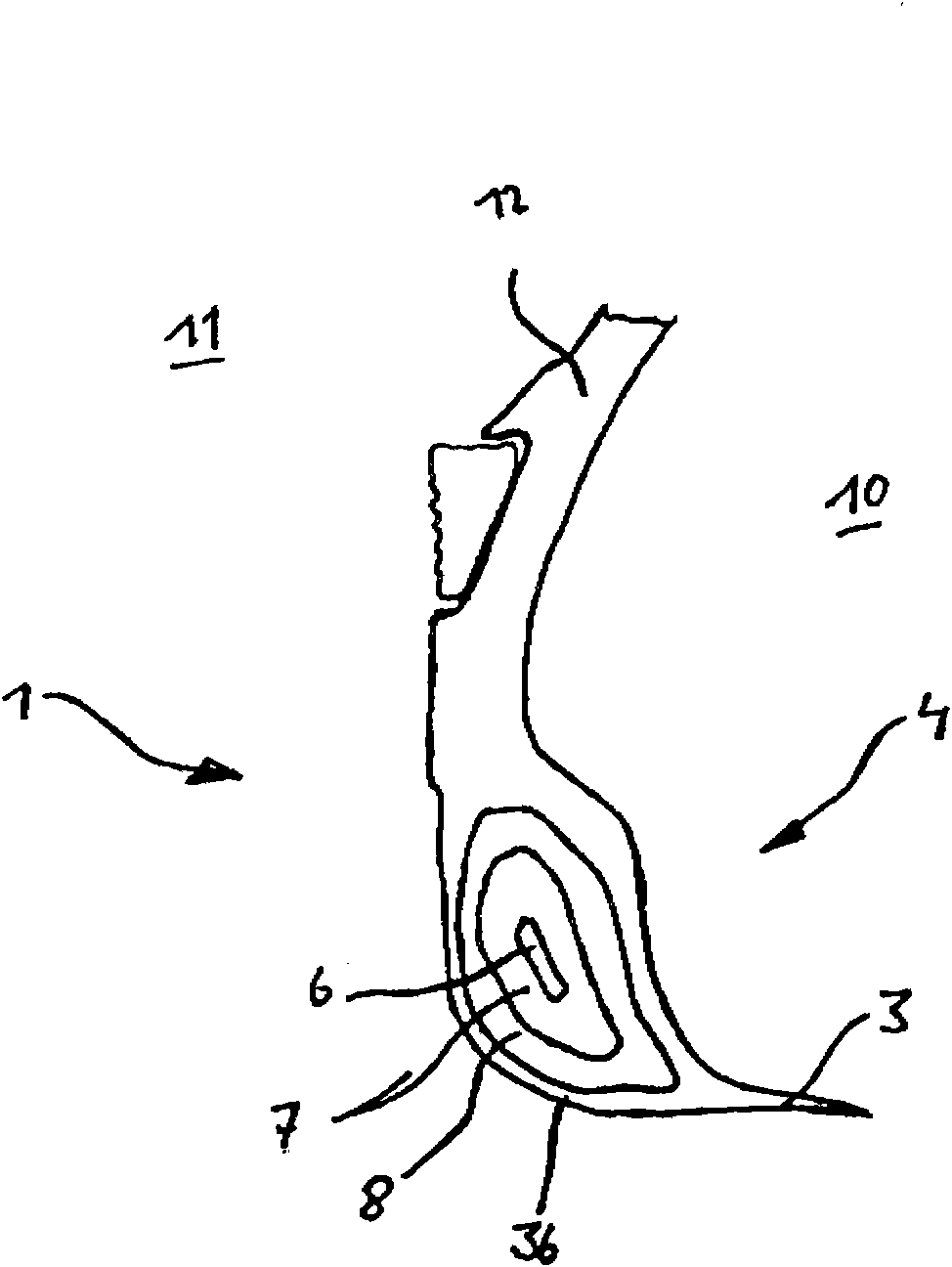

[0068] figure 1 The shown sealing cushion arrangement 1 comprises a sealing lip 3 which, in the application position, fits onto the surface 2 of the face shown here.

[0069] The mask cushion arrangement 1 also comprises a cross-sectional thickening 4 which, in the present embodiment, is arranged between the upper peripheral edge 5 and the sealing lip 3 .

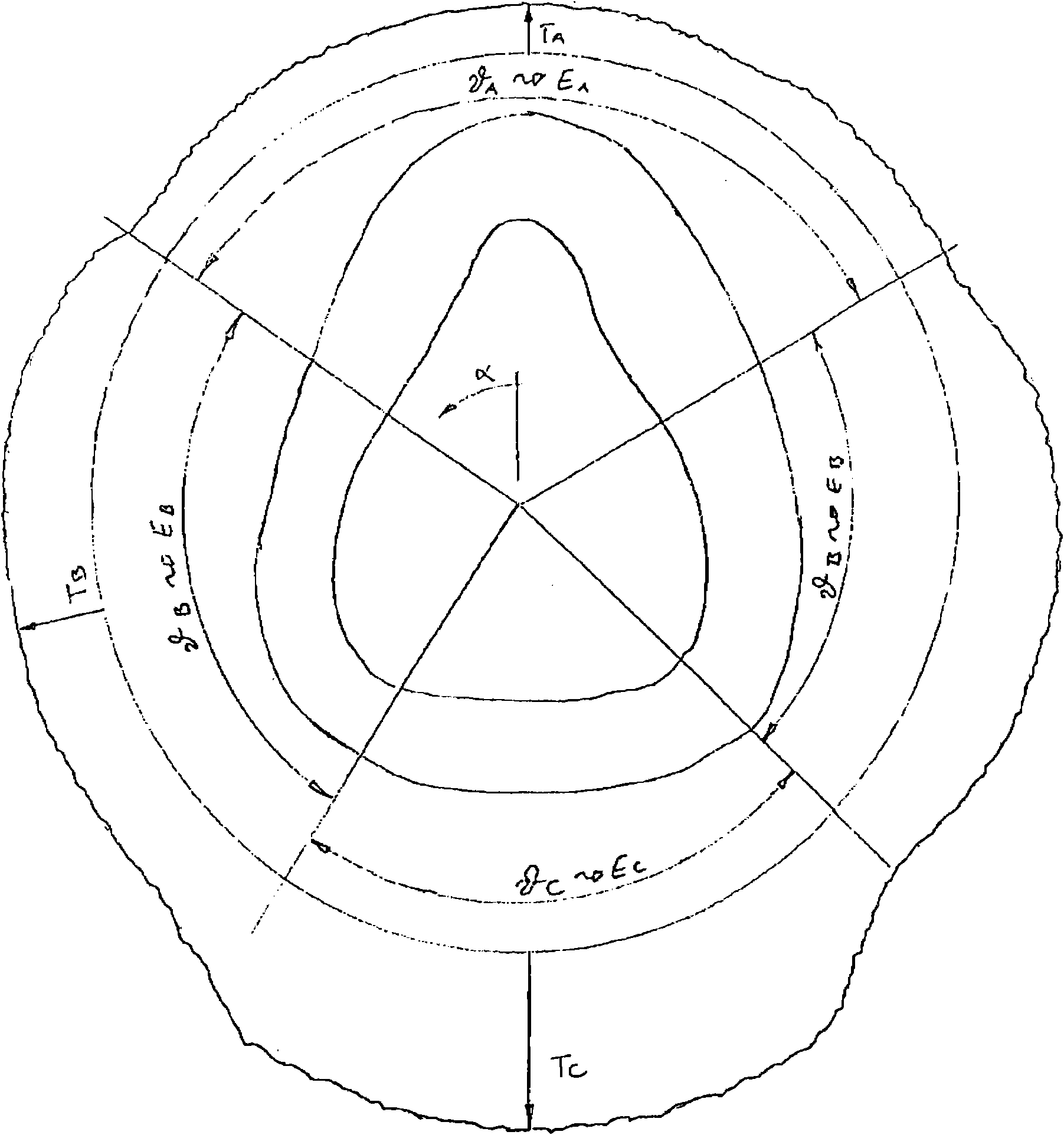

[0070] The cross-sectional thickening 4 is configured such that the Shore hardness of the material forming the cross-sectional thickening varies. The region of material represented here has an almost jelly-like character. The innermost material region 6 has a lower Shore hardness than the adjacent material region 7 , which in turn has a lower Shore hardness than the adjacent material region 8 . The outer region of the cross-sectional thickening is made of a substantially fully cross-linked elastomeric material and has substantially the same Shore hardness as the sealing lip 3 .

[0071] The different material properties ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com