Rotary speed reduction device for automobile crane

A technology of truck crane and reduction gear, which is applied to cranes, transmissions, gear transmissions, etc., can solve the problem that the brake pressure oil is easy to penetrate into the brake, the wear resistance of the brake friction plate is not good, and the sealing performance of the brake piston is not good. Good and other problems, to achieve the effect of improving braking reliability, wide practicability, avoiding extravasation and dust intrusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] An embodiment of the invention will be further described below in conjunction with the accompanying drawings:

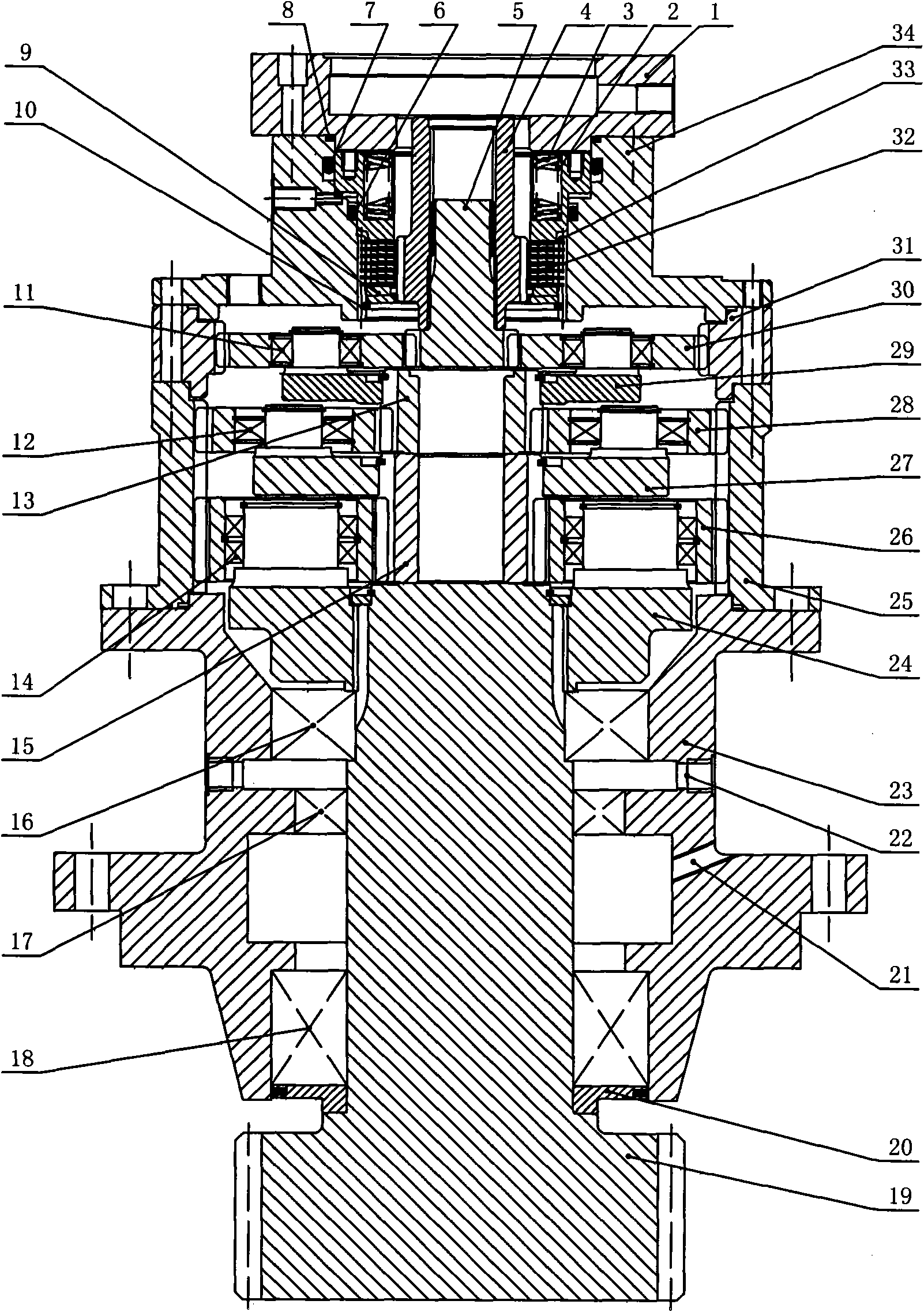

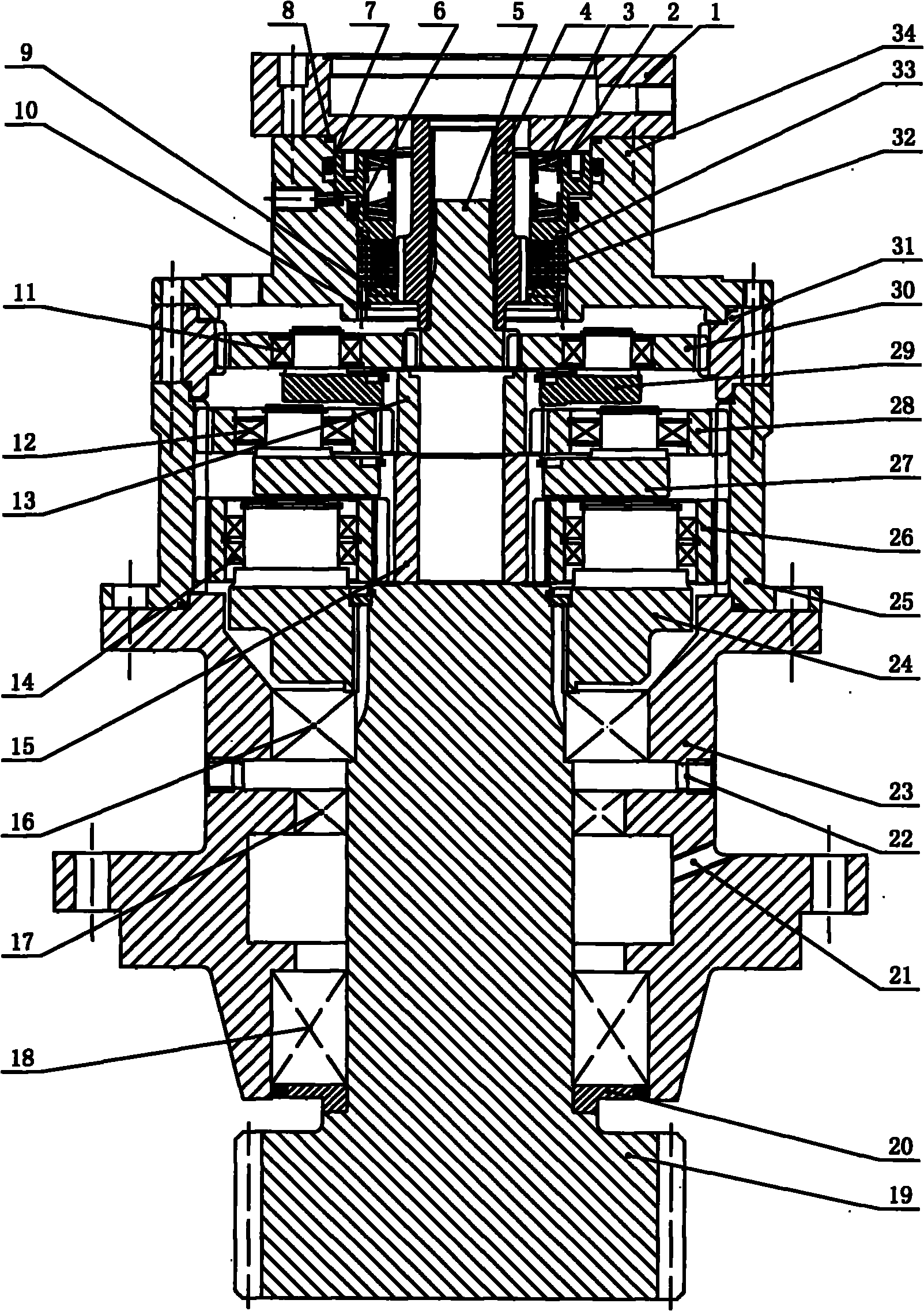

[0010] As shown in the accompanying drawings, the slewing deceleration device of the truck crane is mainly composed of a motor connection plate 1, a brake, a planetary gear reducer, an output gear 19 and its bearings and bearing housings. The motor connecting plate 1 is in the shape of a flange, with a through hole processed in its center and a notch for positioning the motor at the upper end; the entire motor connecting plate is fixed on the brake housing 34 by 8 screws evenly distributed, and on the motor connecting plate 1 An O-ring 8 is housed between the brake housing 34. The brake is composed of a brake housing 34, a brake piston 2, a brake spring 3, 6 dynamic friction plates 32 and 7 static friction plates 33, combined seals 6, 7, gaskets 9, retaining rings 10 and the like. The housing 34 is fixedly connected with the small internal gear 31 and the lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com