High-pressure and impact resistant bearing roller bit with elastic sliders

A roller cone bit, impact-resistant technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve problems such as the impact of broken teeth of the roller cone, damage to the inner hole of the cone, and damage to the sealing system, so as to achieve smooth operation of the drill bit and avoid Severe vibration, good protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

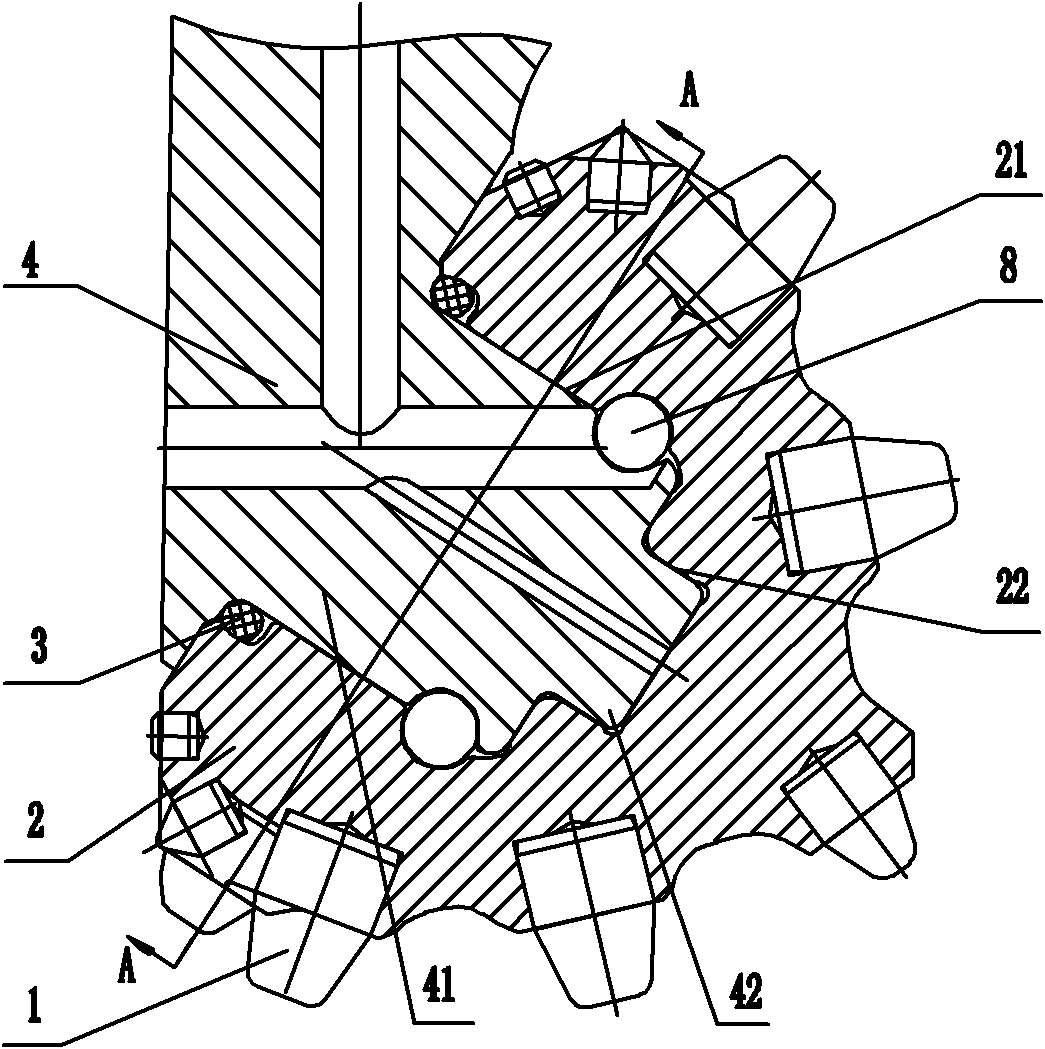

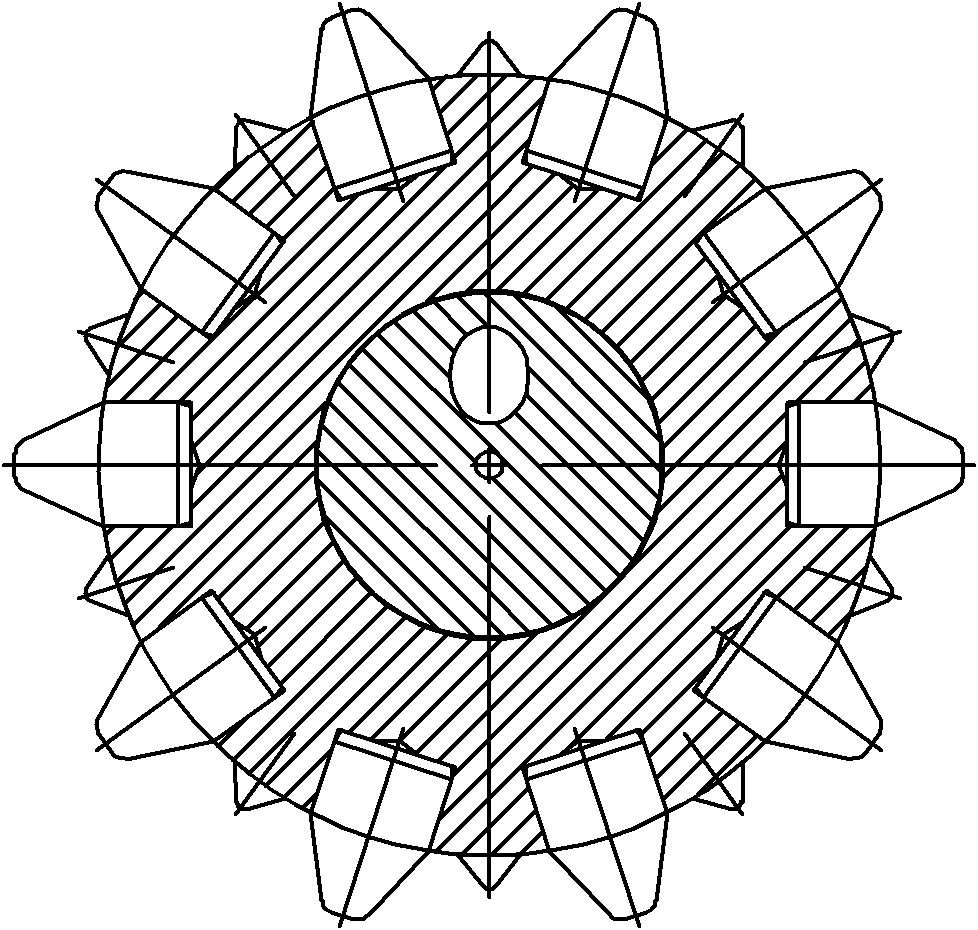

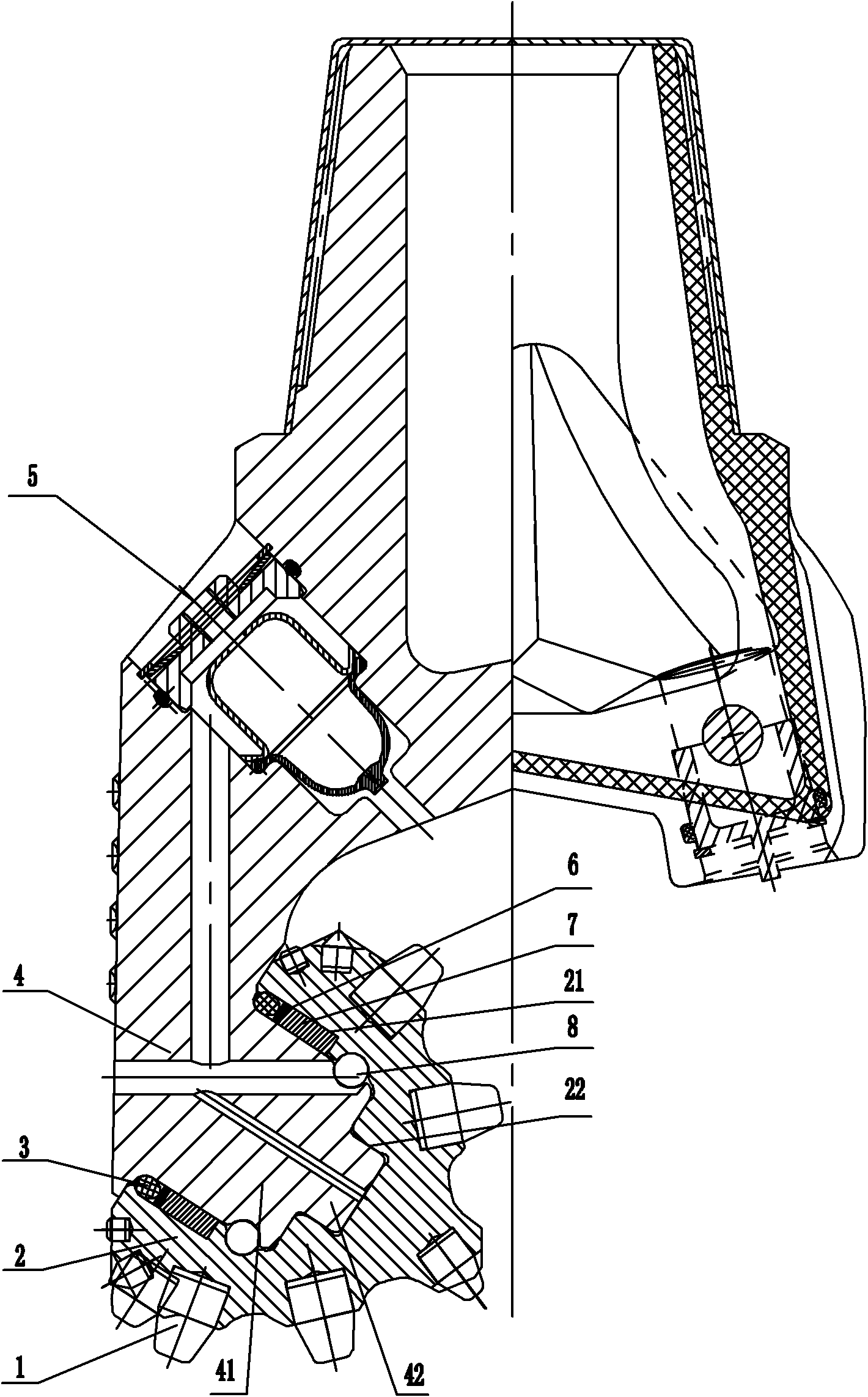

[0023] Referring to the accompanying drawings, a high-pressure and impact-resistant roller cone bit of the present invention includes a cone 2 inlaid with alloy teeth 1, a tooth palm 4 with a large journal 41 and a small journal 42, and the cone 2 is provided with a large journal correspondingly. The shaft hole 21 and the small shaft hole 22, the large shaft hole 21 and the small shaft hole 22 of the cone are respectively set on the large shaft journal 41 and the small shaft journal 42 of the tooth palm journal, and the tooth palm 4 is also equipped with an oil supply system 5. Rubber sealing ring 3, gasket 6 and locking ball 8.

[0024] On the inner wall of the large shaft hole 21, there are annular slides distributed around the axis of the large shaft hole 21. A plurality of elastic sliders 7 are installed in the annular slides. Cooperate.

[0025] The elastic slider 7 is an arc shoe type, and all the elastic sliders are put together in the annular slideway in sequence, for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com