Waste oil guiding and collecting device in wellhead area

A collection device and oil pollution technology, applied in wellbore/well components, earthwork drilling and other directions, can solve the problem of unable to prevent oil pollution from flowing down, and achieve the effect of convenient removal, ensuring safety, and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

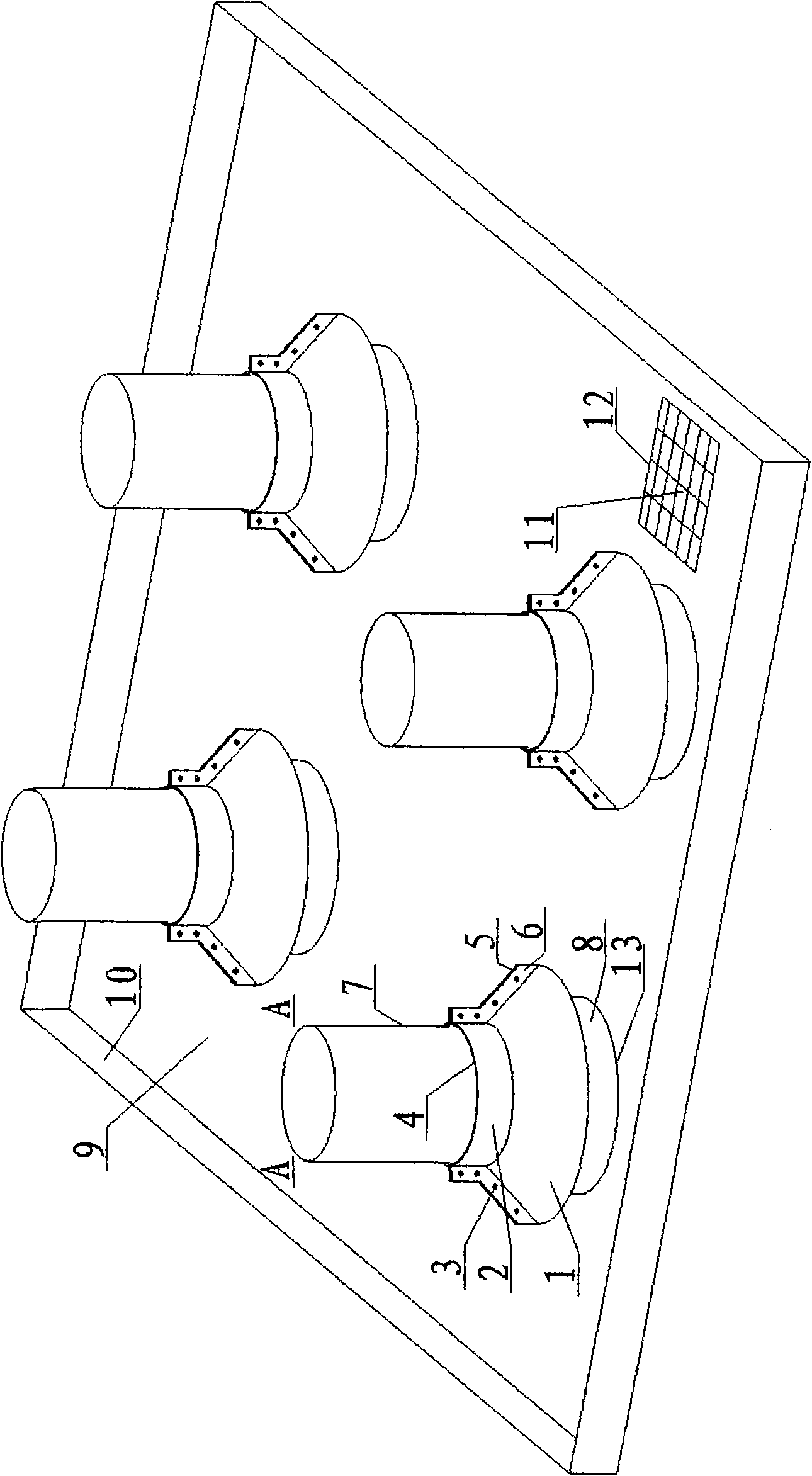

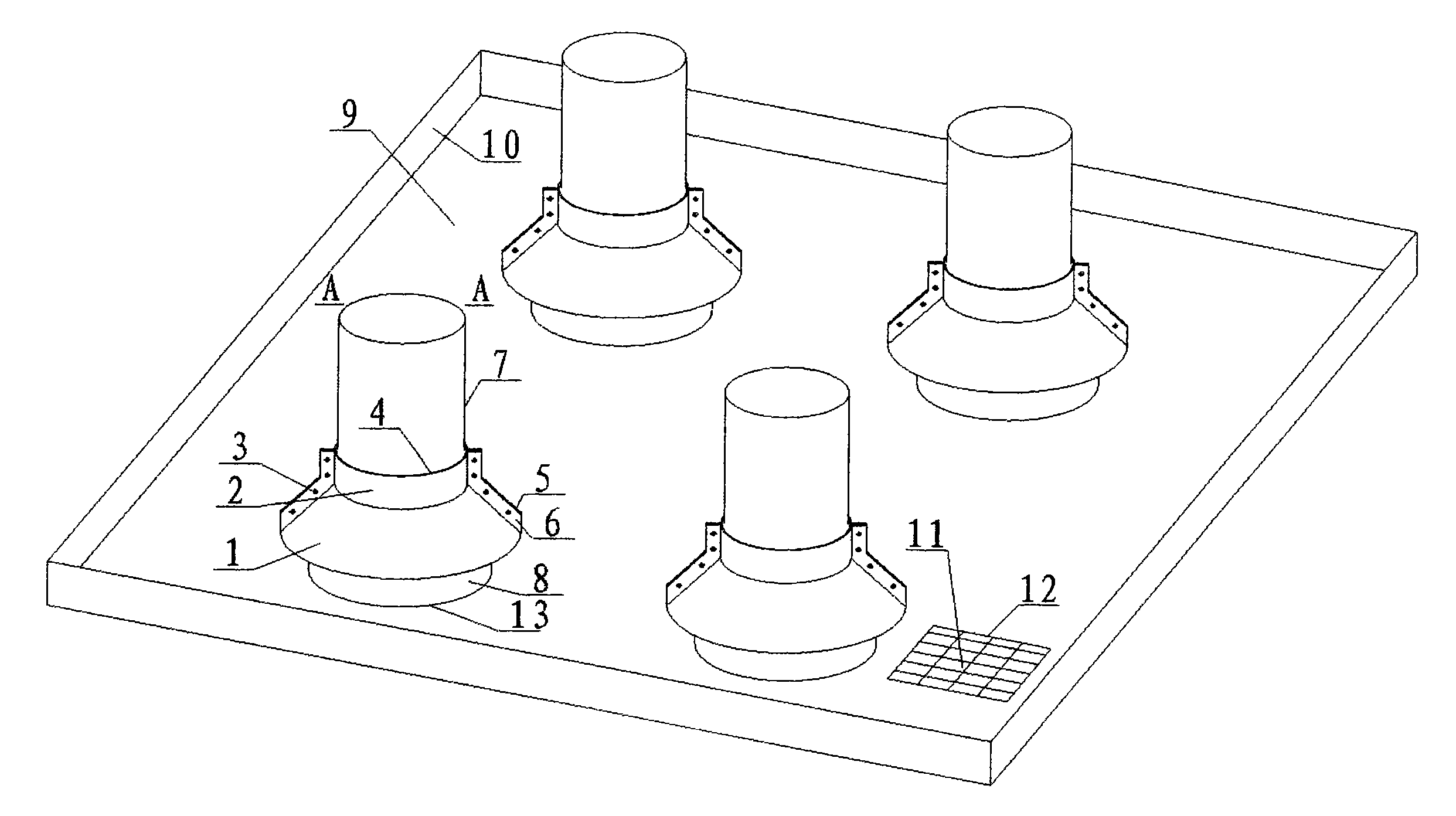

[0014] 1. Laying of impermeable steel plate 9. Firstly, remove the grid plate originally laid in the wellhead area of the platform, and then lay steel plates of appropriate size and weld them together. An annular baffle plate is welded around the waterproof casing 7 and a coaming plate 10 is welded around the wellhead area, and the height of the two is 100-200 mm. Set up an oil stain collection tank 11 at a suitable position in the wellhead area, and cover the top of the collection tank 11 with a grid plate 12 to ensure that the oil dirt can flow into the collection tank 11 smoothly, and ensure the safety of the operator and prevent other items from falling into the collection tank 11 in.

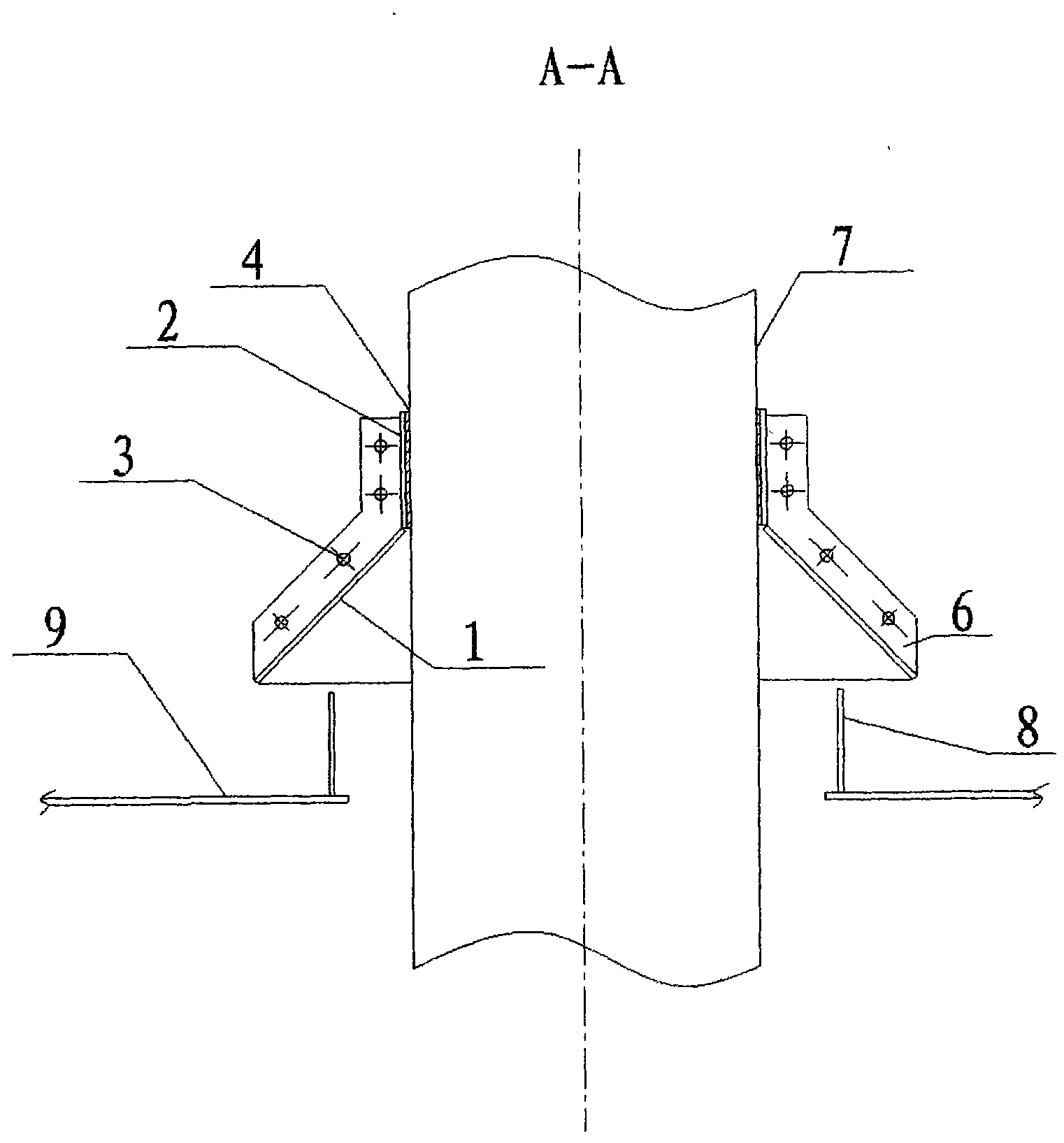

[0015] 2. Production of horn-shaped sleeves. The lower cone 1 and the upper cylinder 2 are rolled into two symmetrical half tiles. The inner side of the connection between the lower cone 1 and the upper cylinder 2 forms a natural cut, so the inner side is welded according to the single ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com