An automatic delivery and replenishment device for a vending machine

A technology for automatic delivery and vending machines, applied in the direction of measuring devices, coinless or similar appliances, coin-operated equipment for distributing discrete items, etc., which can solve problems such as increased operating costs, complex structures, and low space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

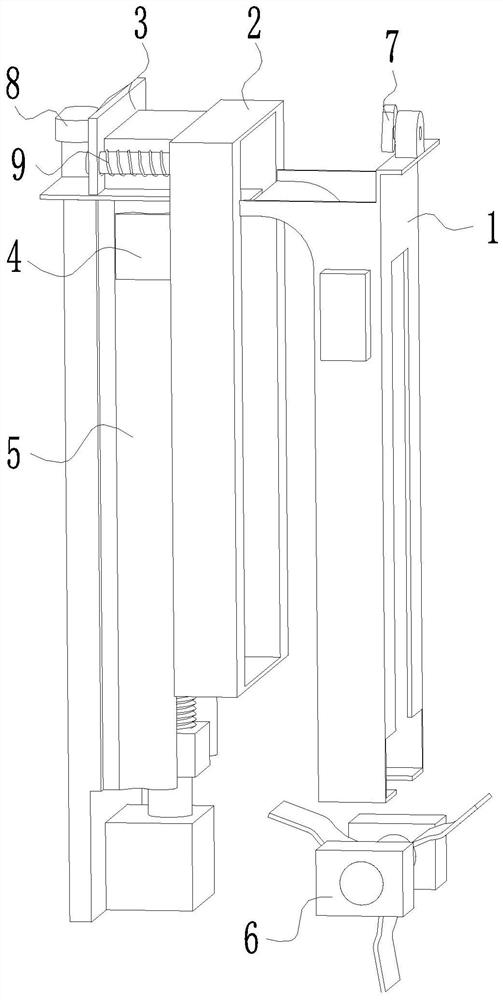

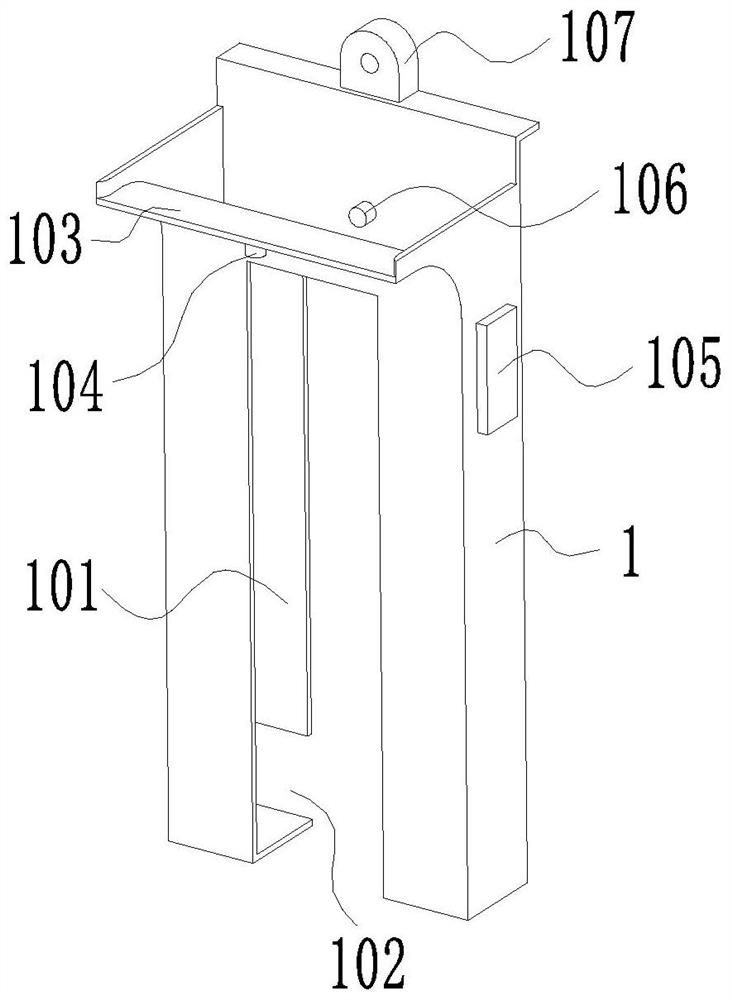

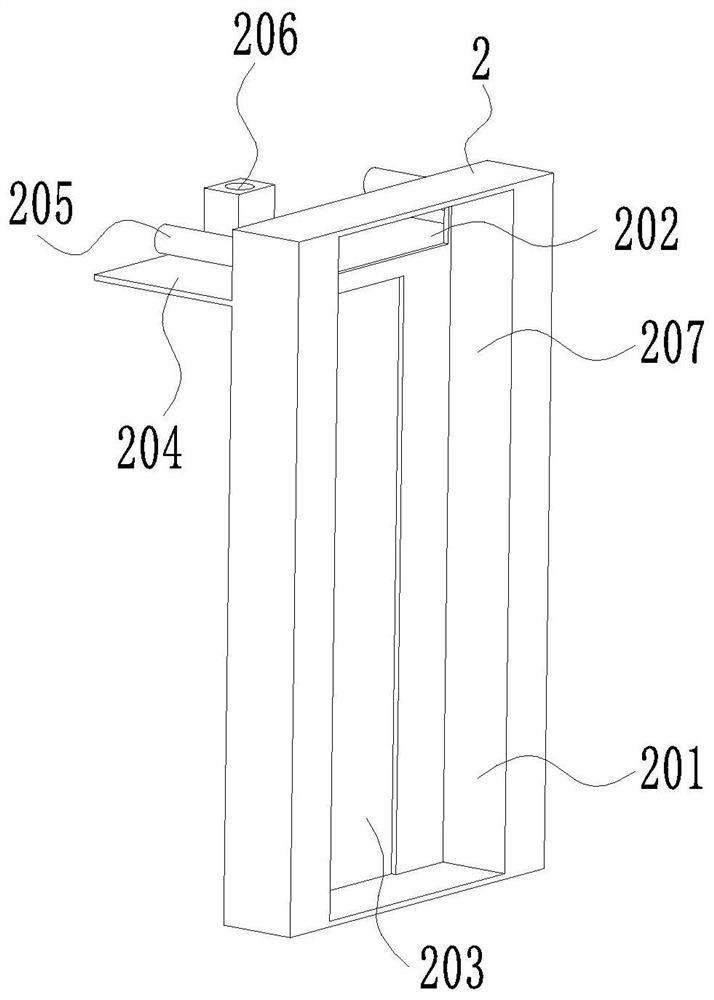

[0050] Specific embodiment one: please refer to Figure 1-8 An automatic delivery and replenishment device for a vending machine, which includes a delivery bin 1, a replenishment bin 2, an ejection assembly 3, a lifting mechanism 4 and a screw mechanism 5.

[0051] A shipping cavity 101 is provided inside the shipping warehouse 1 .

[0052] A chute 103 is provided on the left side of the delivery warehouse 1 , and a first Hall proximity switch 104 is fixed at the lower end of the chute 103 .

[0053] A controller 105 is fixed on the front side of the delivery warehouse 1 .

[0054] The controller 105 is electrically connected to the background server, and the replenishment staff can obtain various data fed back by the controller 105 through the background server.

[0055] An infrared sensor 106 is fixed on the inner wall of the delivery cavity 101 .

[0056] The infrared sensor 106 includes an infrared transmitter and an infrared receiver. The infrared transmitter is fixed ...

specific Embodiment 2

[0069] Specific embodiment two: pallet 401 has built-in weight sensor, and weight sensor is electrically connected with controller 105, and the total weight of spare goods can be passed to controller 105 by weight sensor to electric signal, and the replenishment staff passes the backup The total weight of the goods can know the estimated time of replenishment and the specific stocking quantity.

specific Embodiment 3

[0070] Specific embodiment three: different from specific embodiment one, the push-out assembly 3 is driven by a cylinder, the cylinder is fixed on the upper end of the mounting plate 204, the output end of the cylinder is fixedly connected to the limit plate 302, and the cylinder is electrically connected to the controller 105 , the driving force of the cylinder is greater, and the driving setback is shorter, the efficiency is higher, and the blocking of the pushing block 301 and the pushing groove 202 is effectively avoided.

[0071] Working principle: when the delivery chamber 101 is full of goods, the infrared receiving part cannot receive the infrared beam emitted by the infrared emitting part, the controller 105 does not receive the electrical signal from the infrared sensor 106, and the motors do not operate.

[0072] After the goods at the bottom of the delivery cavity 101 are discharged, the goods on the upper layer fall one by one, and there is no goods blocking betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com