Manufacturing WTG blade having a spar

A technology of wind turbines and wind turbines, applied in wind engines, wind engines consistent with the wind direction, wind power generation, etc., can solve problems such as increasing WTG costs, and achieve the effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

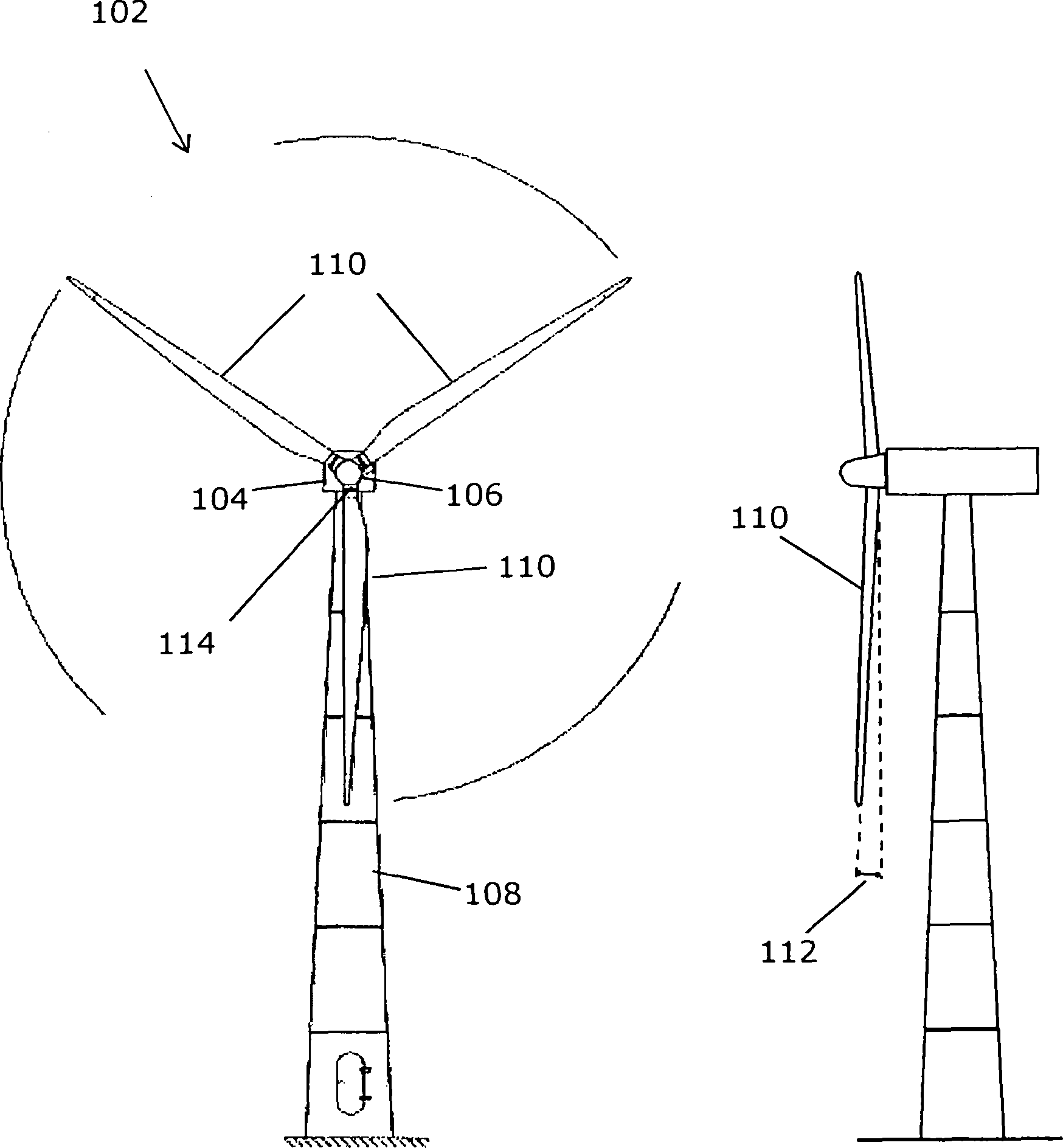

[0063] figure 1 A wind turbine generator 102 is shown having a nacelle 104 and a hub 106 pivotally mounted on the nacelle 104 by a shaft. The nacelle 104 is mounted on a wind turbine tower 108 via a swivel joint. The hub 106 of the wind turbine includes three wind turbine blades 110 connected to the hub at blade root ends 114 . The hub rotates about the central axis of the rotor shaft of the wind turbine in a rotational plane substantially perpendicular to the central axis. In the example shown the length of the wind turbine blade is about 40 meters, but the blade length can also generally be between 25 and 75 meters.

[0064] In the plane of rotation of the blades, it can be seen from the figure that the blades are separated from each other by a sweep angle of 120 degrees. A side view of the wind turbine is shown on the right side of the figure. As can be seen from the side view, the wind turbine blade is tapered with a cone angle 112 offset from the plane of rotation. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com