Rotor hybrid magnetic bearing in flat horizontal coil

A hybrid magnetic bearing and horizontal line technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of magnetic bearings with complex structure, large mass, and high energy consumption, and achieve increased bearing capacity, reduced mass, processing and assembly convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

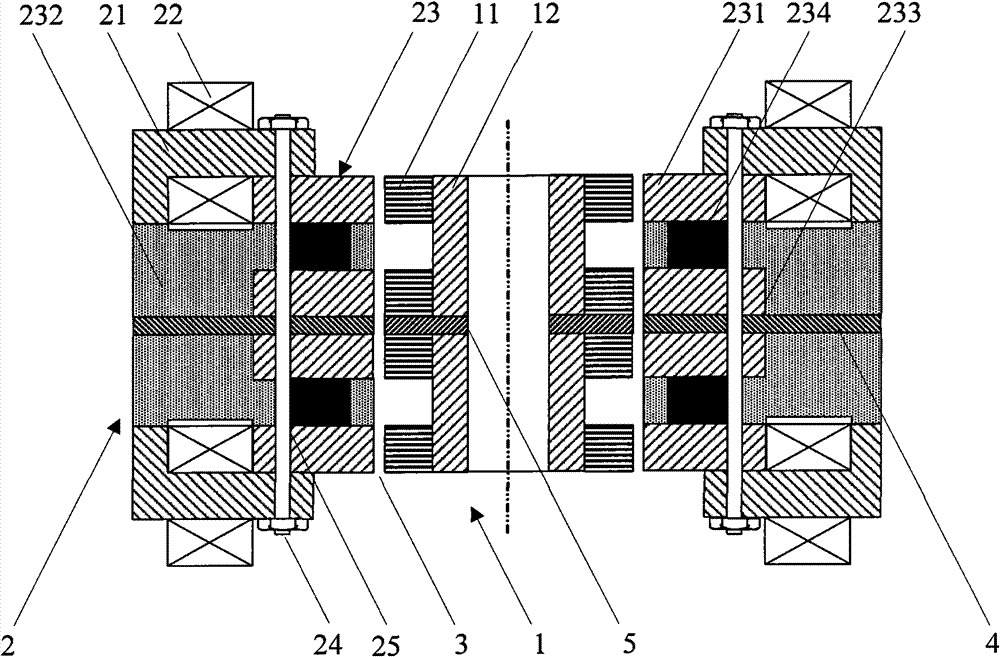

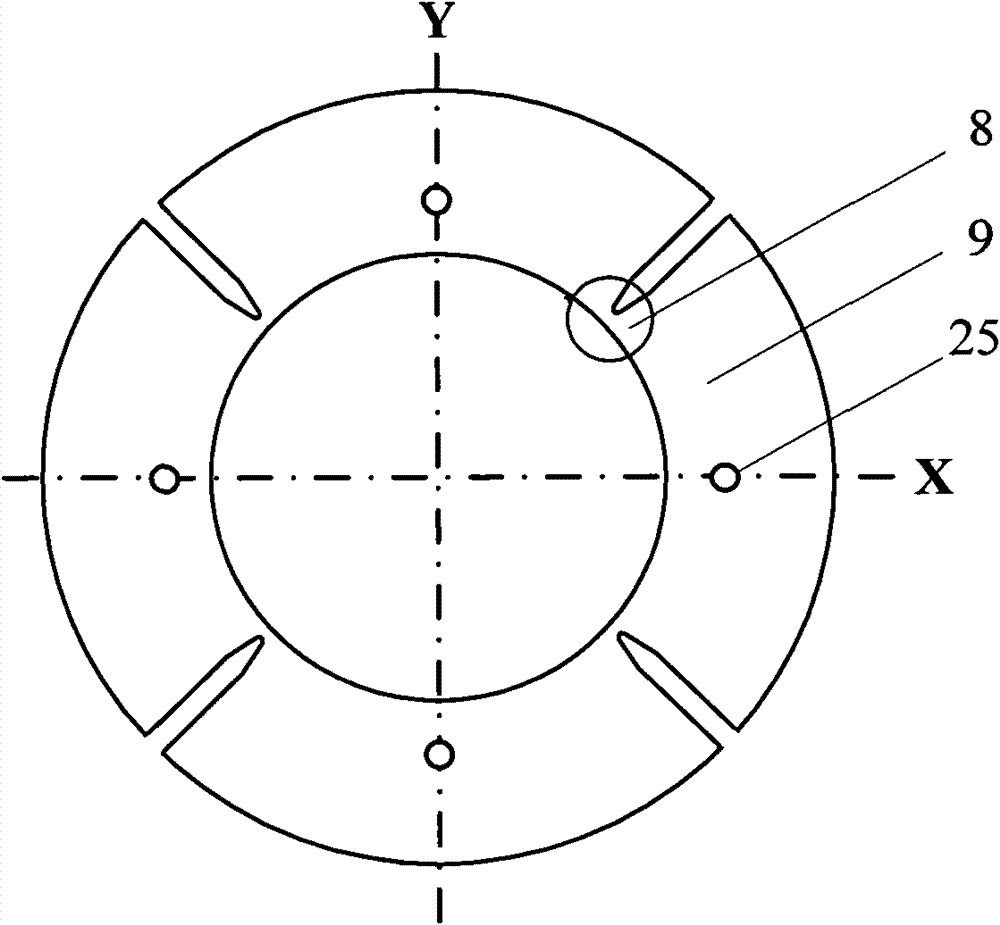

[0041] see figure 1 , the flat type horizontal coil outer rotor hybrid magnetic bearing of the present invention is a flat type low loss four-axis hybrid magnetic bearing comprising a horizontal coil, radially uniform magnetic poles and an inner rotor. The horizontal coil hybrid magnetic bearing constitutes a four-axis hybrid magnetic bearing, the upper and lower bearings are symmetrically placed, and the middle is separated by a spacer ring 4 and a spacer ring 5 .

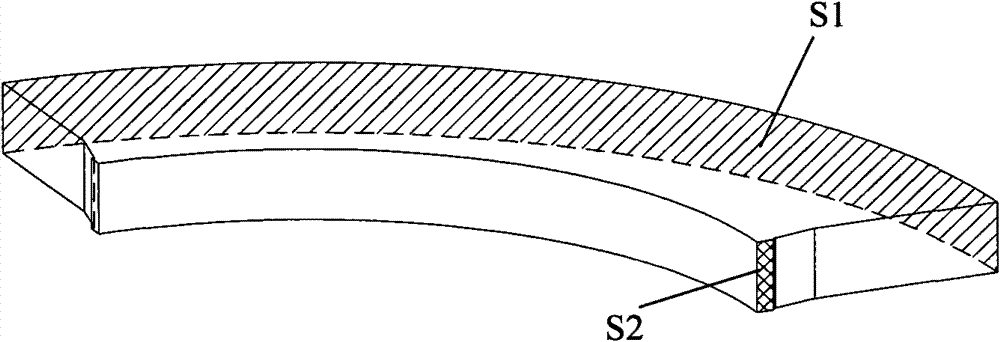

[0042] Each of the two-axis single-sided horizontal coil hybrid magnetic bearings is composed of a rotor 1 and a stator 2 . The rotor 1 is installed inside the stator 2 to form an inner rotor. The rotor 1 is composed of a rotor core 11 and an inner magnetically permeable ring 12 , wherein the rotor core 11 is coaxially sleeved on the outside of the inner magnetically permeable ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com