Generation device and method of parallel light path in vertical direction

A vertical direction and generating device technology, which is applied in the direction of using optical devices, measuring devices, and measuring fixed angles, etc., can solve the problems that fine-tuning takes a certain amount of time, and it is difficult to maintain a high level, so as to achieve the effect of ensuring verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

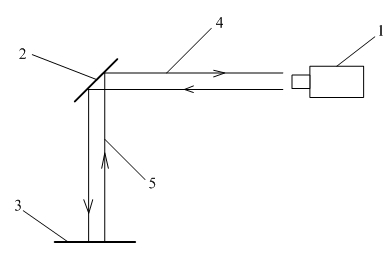

[0013] Such as figure 1 As shown, the device for generating parallel optical paths in the vertical direction includes a laser light source 1, a total reflection mirror 2, and an oil mirror 3, wherein the laser light source 1 and the total reflection mirror 2 are correspondingly arranged, and the oil mirror 3 is correspondingly arranged below the reflector 2.

[0014] The total reflection mirror 2 and the oil mirror 3 are at 45° to each other.

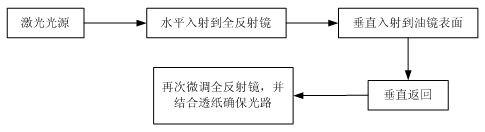

[0015] Such as figure 2 As shown, make the horizontal laser incident on the 45-degree reflective mirror, precisely adjust the angle of the mirror so that the laser is vertically incident on the oil mirror mirror, and move the lens paper back and forth on the long optical path to make the incident laser and the laser reflected by the oil mirror surface The beams are completely coincident, which ensures that the downward incident light path is strictly perpendicular to the ground surface, and also ensures that the incident light path in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com